Inventory management

Master data for warehouse goods.

Manage inventory according to different units of account (basic unit, packaging unit, storage unit) for different management purposes.

Warehouse management by shipment (batch/lot)/serial number.

Warehouse management by barcode

Manage inventory by expiration date. The function notifies warehouse managers when the warehouse expires.

Query, display and report inventory with errors/reshipment/damaged/unused.

Retrieve, display and report warehouse goods with negative residuals and marks to track/manage.

Order management

The ability to set up the order warehouse level, minimum inventory and maximum inventory for each item to avoid excess/deficit of inventory. When the inventory balance decreases to the order inventory level, the system will automatically send a notification to remind the warehouse manager to take timely action.

The function of setting up the optimal order level for each item to practice the quantity of orders from large suppliers and effectively use the cost of shipping/communication. When the inventory is reduced to the order level, the system will automatically set up a purchase request form (for raw materials/goods) or a production requirement (for components) according to the specified optimal order quantity and transfer it to the warehouse manager.

Inventory demand planning

Check the material requirements for production with inventory in this Division; convert the missing materials into a purchase requirement and connect to the accounting system.

The ability to set up the optimal inventory level for each warehouse inventory.

Check the materials required for production with warehouse materials in this system

Warehouse system structure

Lock/lock storage location function.

The function of querying and displaying the status of the storage location.

Manage the detailed storage location system according to each shipment. Retrieve and display information about each sub-shipment arranged in the same storage location/different storage locations.

Inventory rotation

- Delivery ship:

+ Create a delivery form from the customer's Order.

+ Create a delivery invoice from the delivery invoice to the customer.

+ Create other delivery forms (internal delivery, delivery for/know/disappear, sample delivery, delivery for advertising/promotion, and other purposes).

- Receiving late:

+ Create a receipt from the Order with the supplier.

+ Create a receipt from the supplier's purchase invoice.

+ Create other receipts (internal receipts, receipts for/indication/dissals, receiving samples, receiving goods for advertising/promotion, and other purposes

The ability to process certificates from warehouse turnover according to each certificate/group of certificates from the word to optimize the rotation of warehouse items that are similar or related to each other.

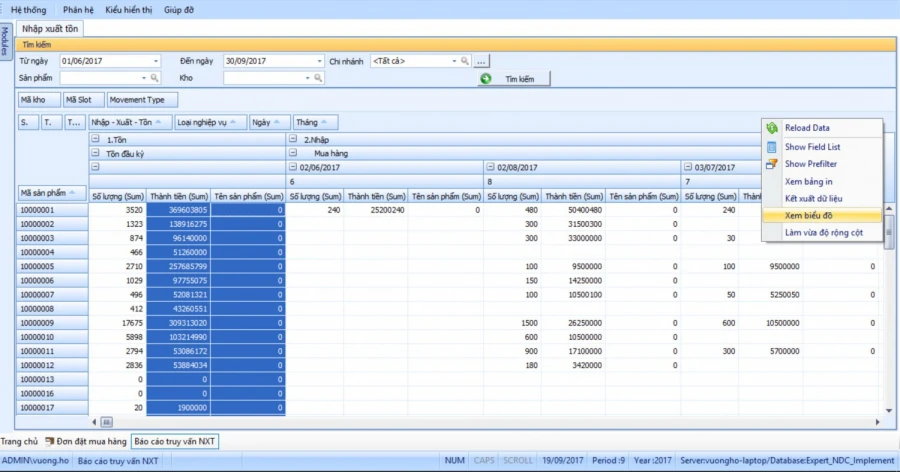

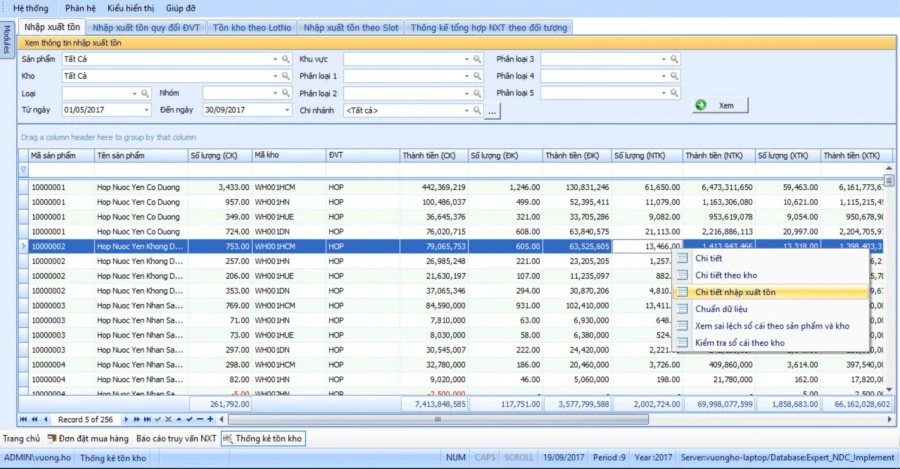

SOME INTERFACE SCREENS OF THE WAREHOUSE-INVENTORY MANAGEMENT SUBSYSTEM

Figure 1: Import and Export Inventory Report by Movement Type

Figure 2: Import and Export can Drill Down to the original document