Paper packaging is produced from paper materials used to pack food, goods, items, etc. They help preserve goods during the process of storage, loading and unloading, transportation from factories to distributors, agents, stores to consumers. Because it is environmentally friendly, not harmful to health, it is applied to many industries such as: Food - Cosmetics - Textiles - Electronics - Furniture wood - Agricultural processing - E-commerce, ... so the paper packaging industry is increasingly receiving attention and investment in development with eye-catching, novel designs and many other useful functions.

Paper packaging has the main product lines:

PRODUCTION PROCESS

The tariff war between the US and China pushes the tariff rate on paper packaging products to 25% from the end of 2019, which has created a trend of shifting foreign-invested packaging factories from China to ASEAN, including Vietnam.

It is predicted that Vietnam's export value will grow well in 2021 thanks to the advantages of the Vietnam-EU Free Trade Agreement (EVFTA); Comprehensive and Progressive Trans-Pacific Partnership (CPTPP)... to help increase industries that need to use paper packaging a lot such as agriculture, seafood, garment and leather, telephone and electronics, ... not to mention the domestic retail and e-commerce market is also forecast to grow by over 10%.

According to VPPA, the restriction of plastic waste, nylon bags and increasing the incentive to use alternative paper packaging has become a worldwide trend, regulated by many countries into laws, especially in Vietnam, which is showing signs of extensive and strong development in 2021 onwards.

Packaging paper manufacturing businesses also face the challenge of a lack of production materials and prices that remain high in the first 6 months of 2021 because the main supplier of recalled paper is North America, Europe and Japan, which are still strongly affected by the COVID-19 epidemic.

Social distancing reduces the collection rate of paper materials, in addition, the lack of containers and freight is also a big problem, so the lack of raw materials and prices are still at a high level that is very clearly shown.

Meanwhile, the domestic collection source is low, the quality of raw materials is not high, not enough to meet demand when new factories with capacity are expected to increase by 1 million tons in 2021.

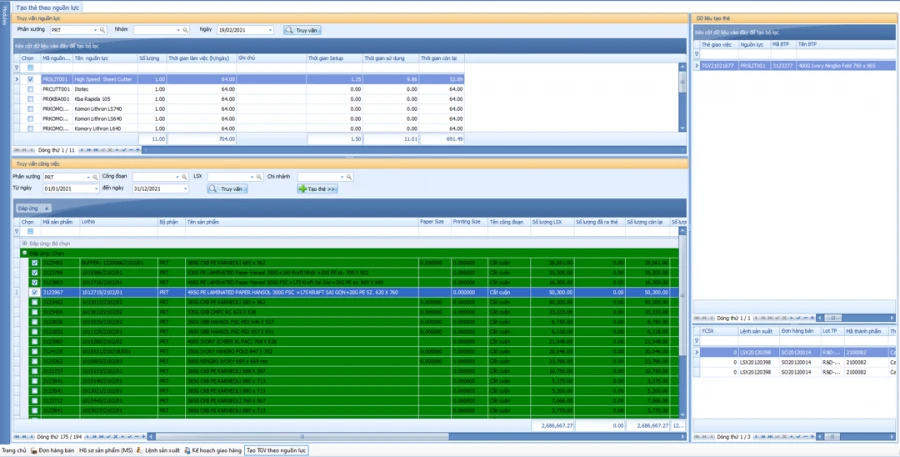

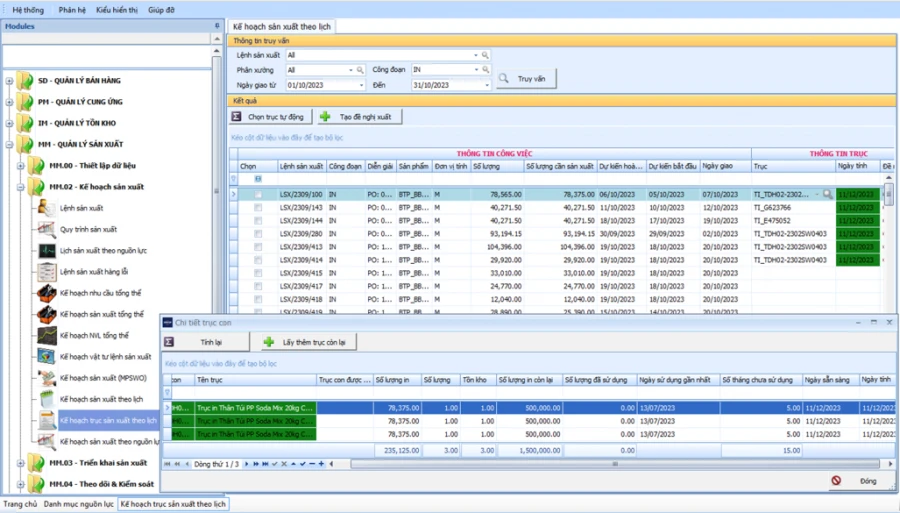

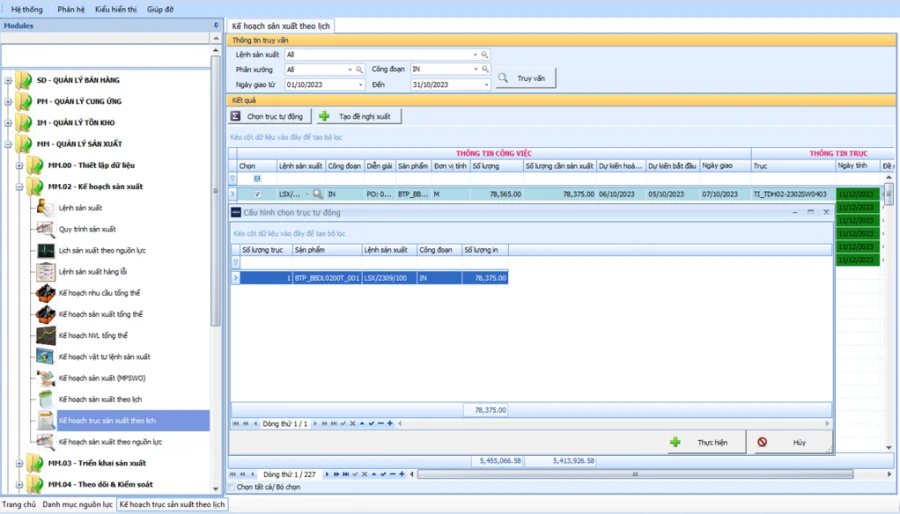

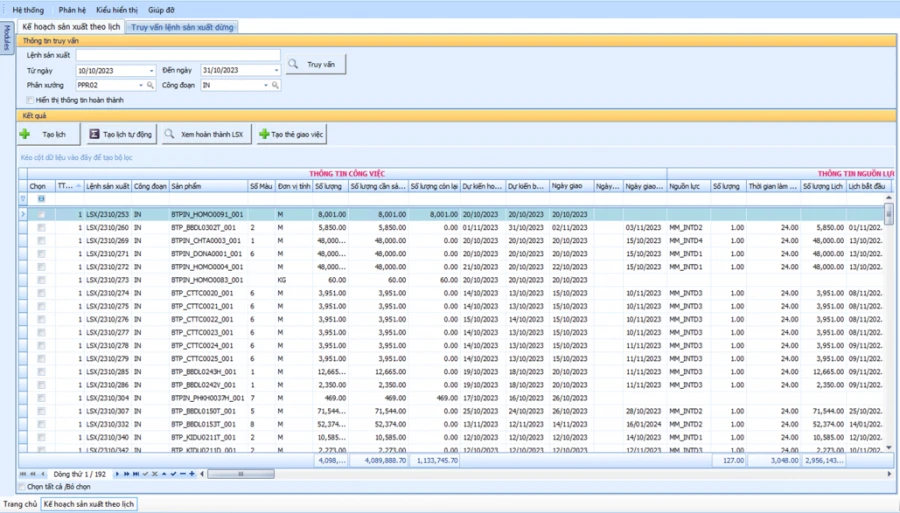

Paper packaging enterprises mainly produce according to Orders/Contrats, so the monitoring process from the Business stage - Production planning - Preparation of production materials - Production statistics - Warehouse semi-finished products - finished products must be attached to the Order/Conct. Therefore, businesses face difficulties in the planning stage, importing raw materials, machinery and equipment according to the "Just In Time" principle.

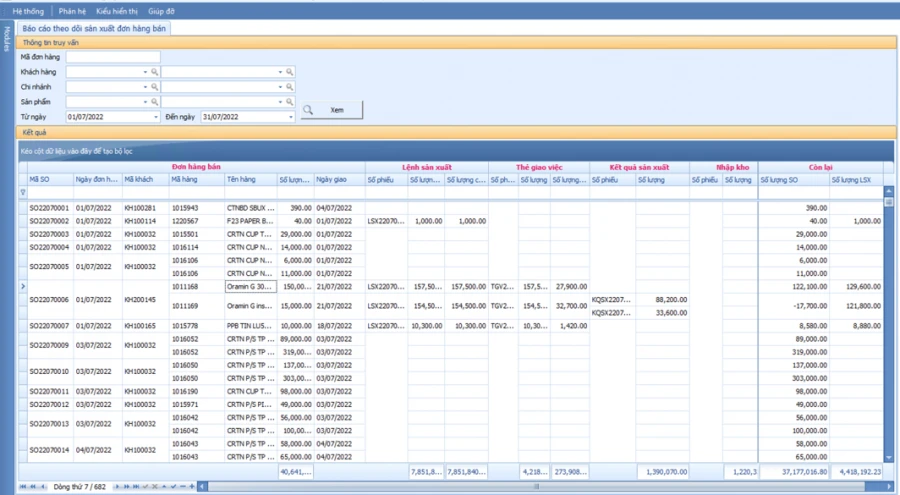

For Sales Department:

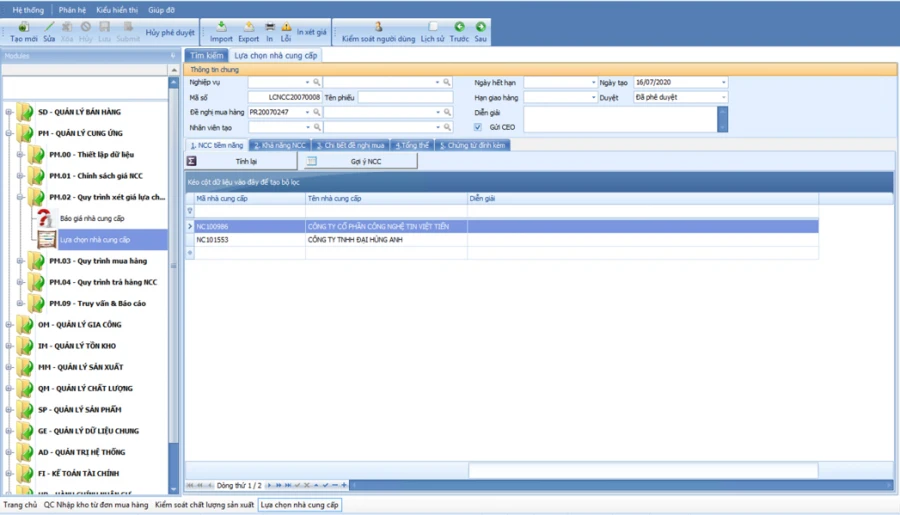

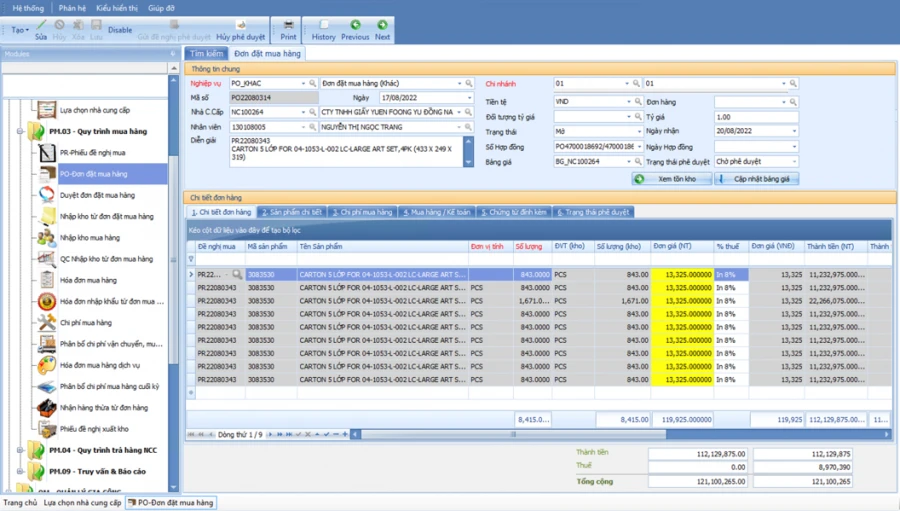

For the Purchasing Department:

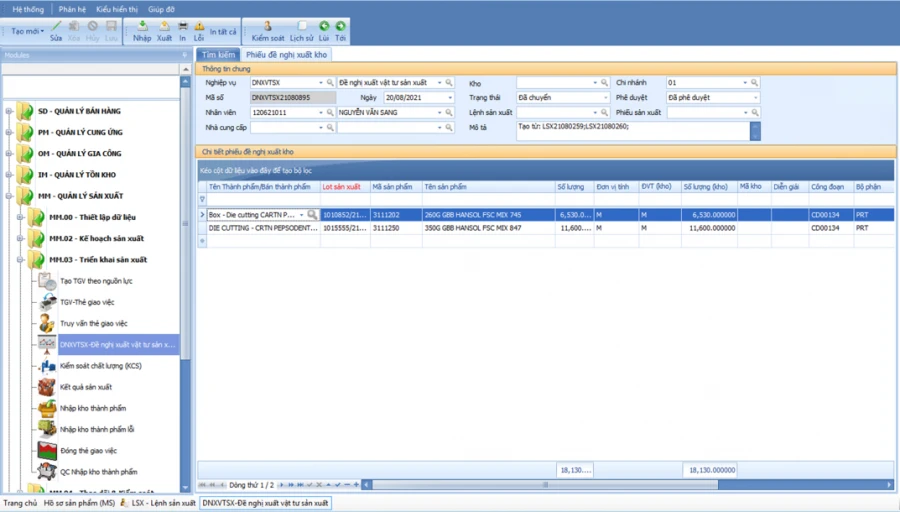

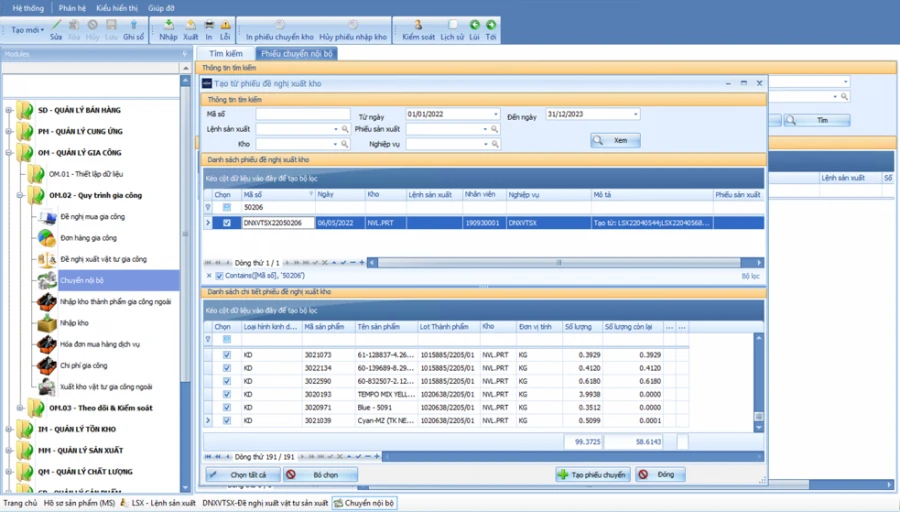

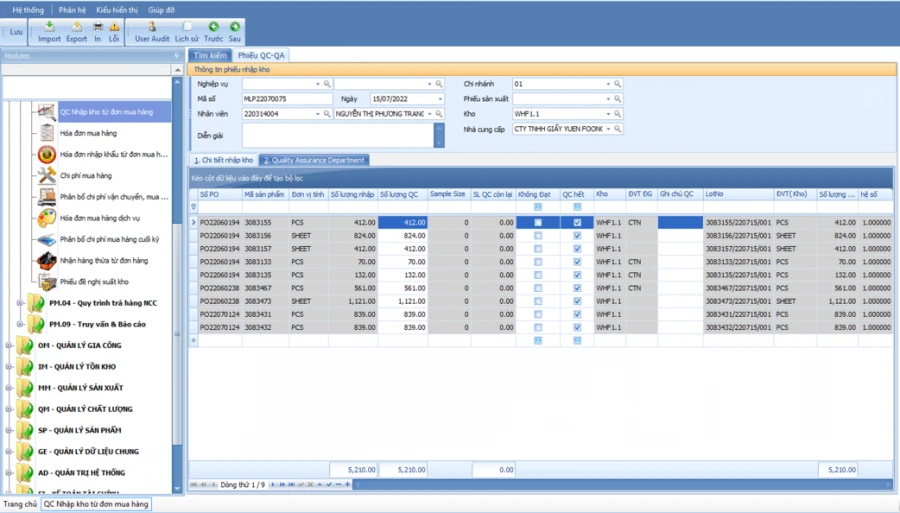

For Warehouse Management:

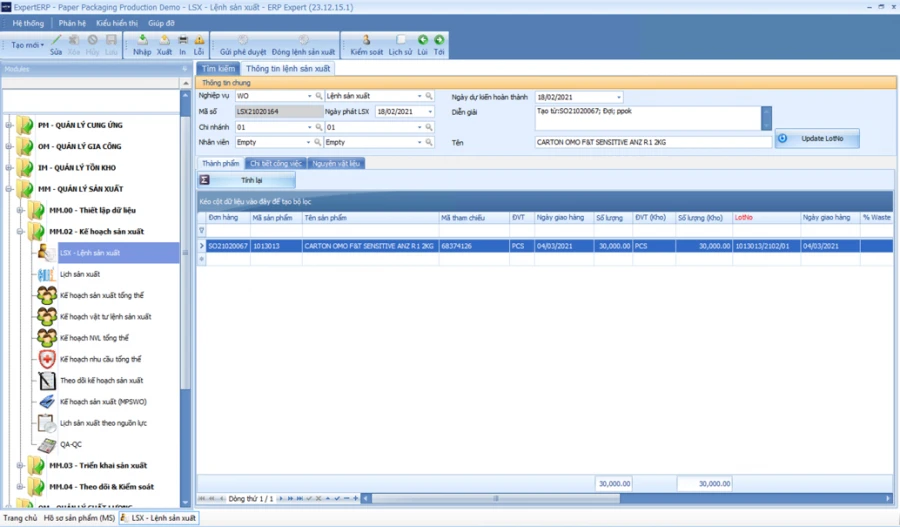

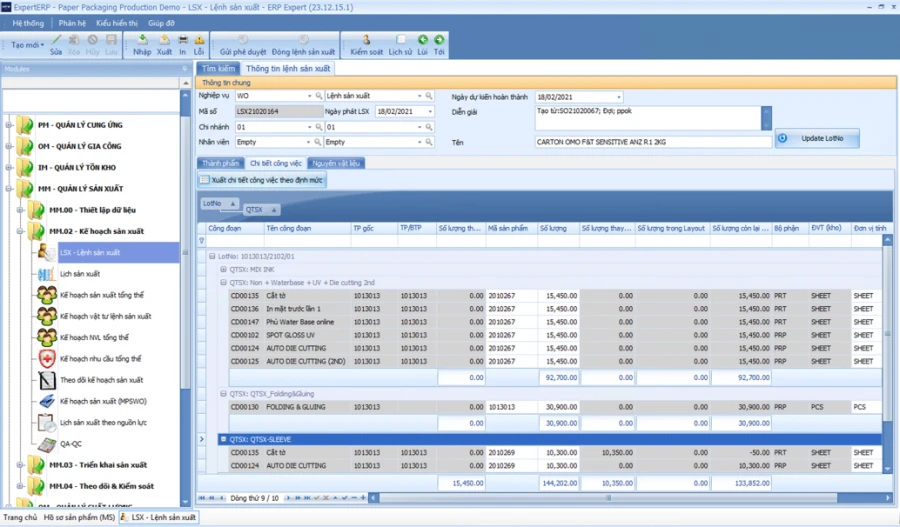

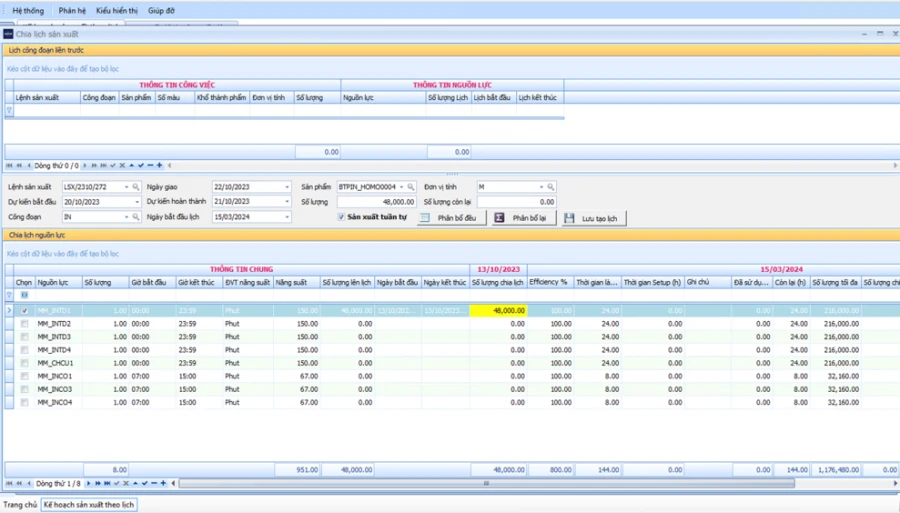

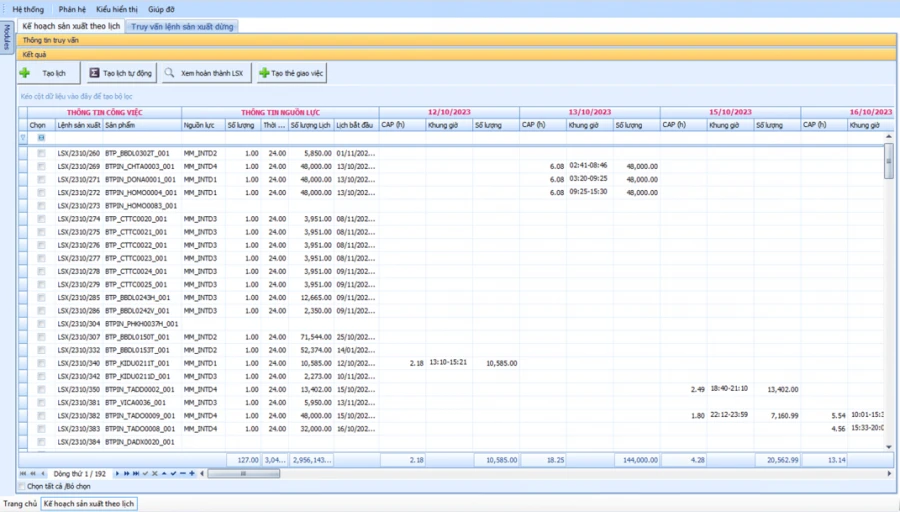

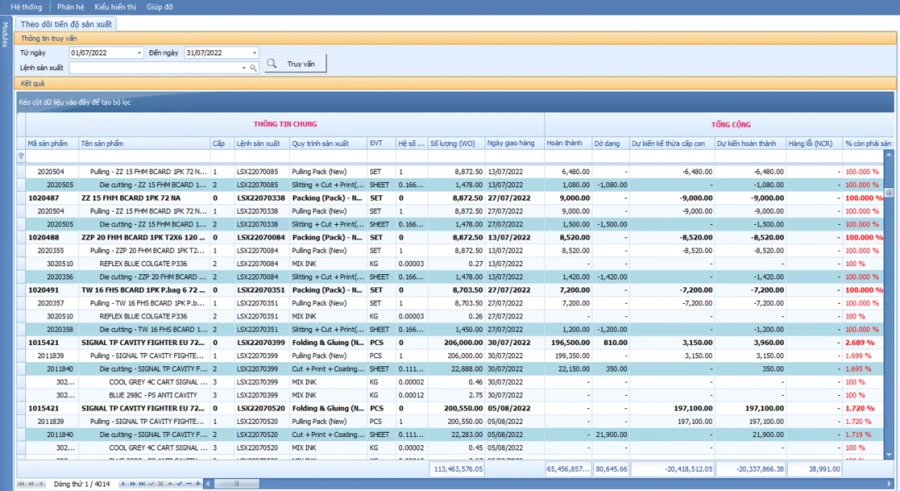

For Production Management:

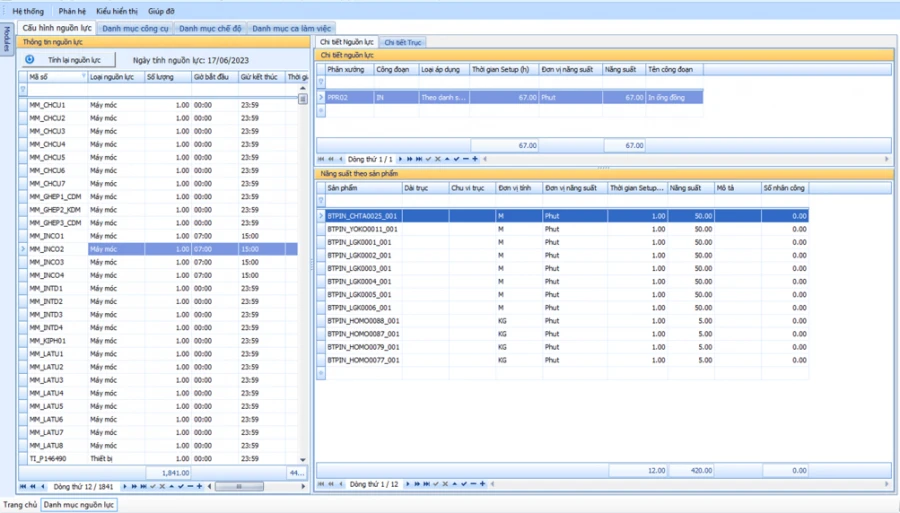

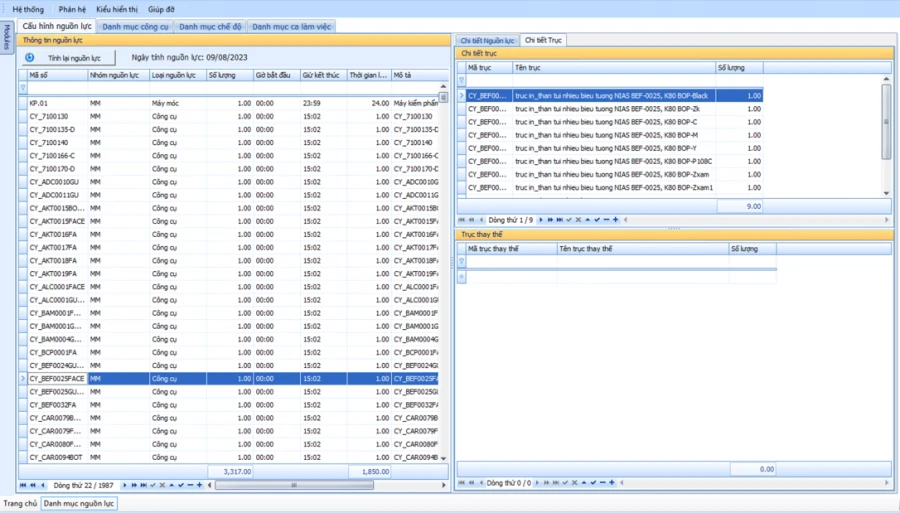

For Machine and Equipment Management:

EXPERT ERP SOLUTION

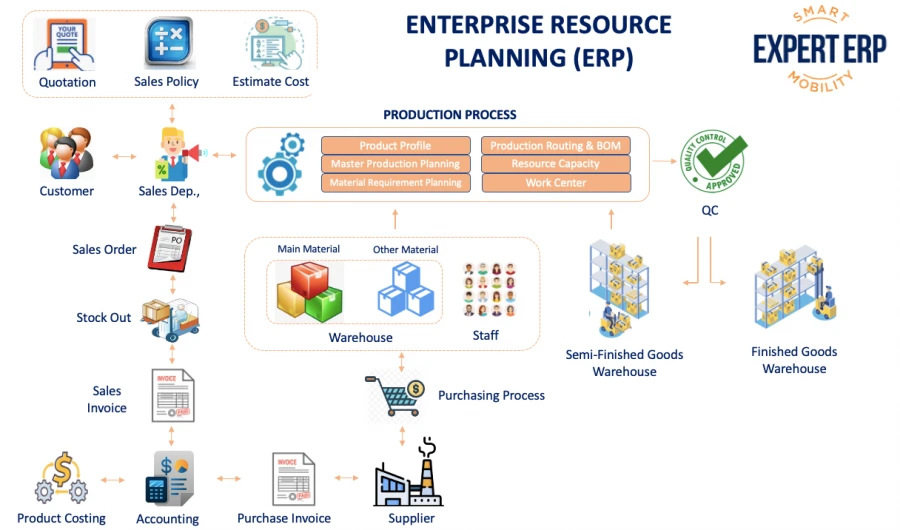

With in-depth knowledge and experience in research, analysis and development of Enterprise Resource Planning (ERP) Solutions in Europe. We build ExpertERP Solutions according to advanced technology, international standards with a process that both meets the multidisciplinary direction and can solve specific problems and intensive management requirements by industry.

With a team of experienced experts, it has been successfully deployed for many FDI businesses and domestic businesses of the paper packaging industry in Vietnam. ExpertERP Total Management Solution applies to all business - production activities of enterprises, thanks to the application on a single platform of systems, software and databases, the flow of information data ensures transparency, seamless, instant, accurate. Allow access to data and statistics, instant reports, "Anytime - Anywhere - On any device", support the Leadership to make timely and correct decisions.

The Covid 19 pandemic situation will continue to have a bad impact and cause many difficulties for the production - business activities of businesses in general, the paper packaging industry in particular. However, this is a favorable time for businesses to stabilize, re-regulate all activities, and move towards a comprehensive "DIGITAL TRANSFORMATION" of the company. If you want to be highly capable of improving management, increasing labor productivity, and increasing profit margins, you must digitize all core activities of the enterprise, which is the Application of ENTERPRISE RESOURCE PLANNING SOLUTION (ERP). With successful deployment experience for many businesses in the industry, GMC's Expert ERP Solution will help your business achieve these key goals.

EXPERT ERP ENTERPRISE RESOURCE PLANNING SOLUTION MODEL

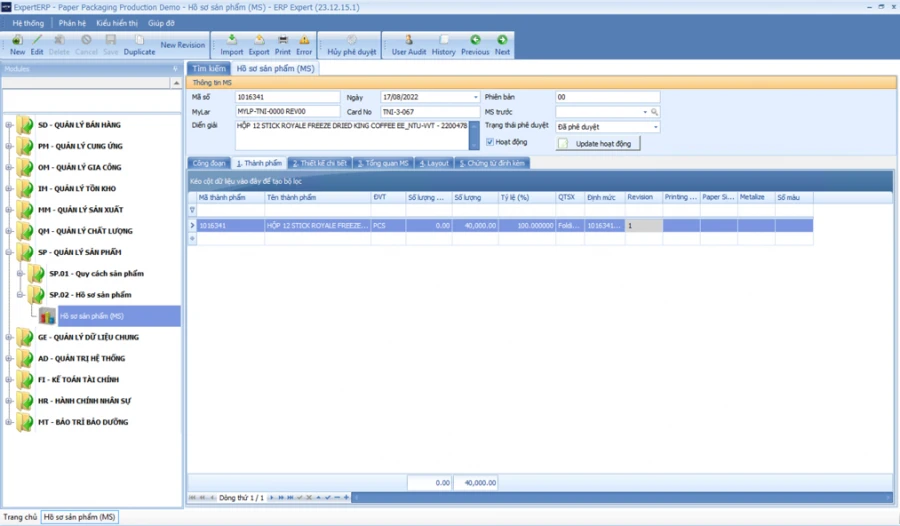

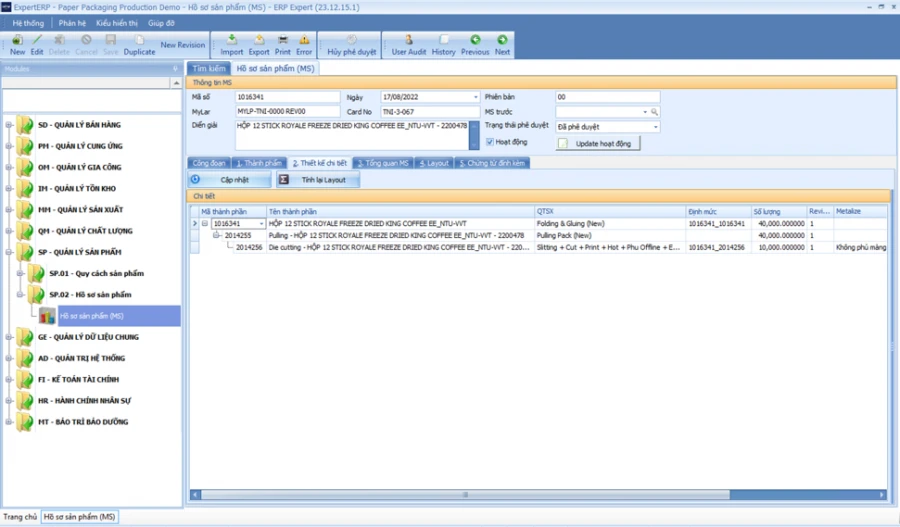

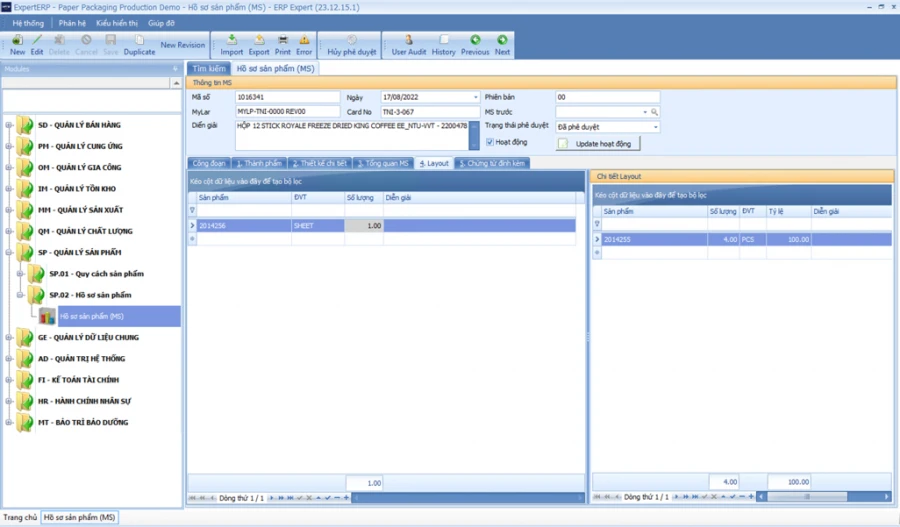

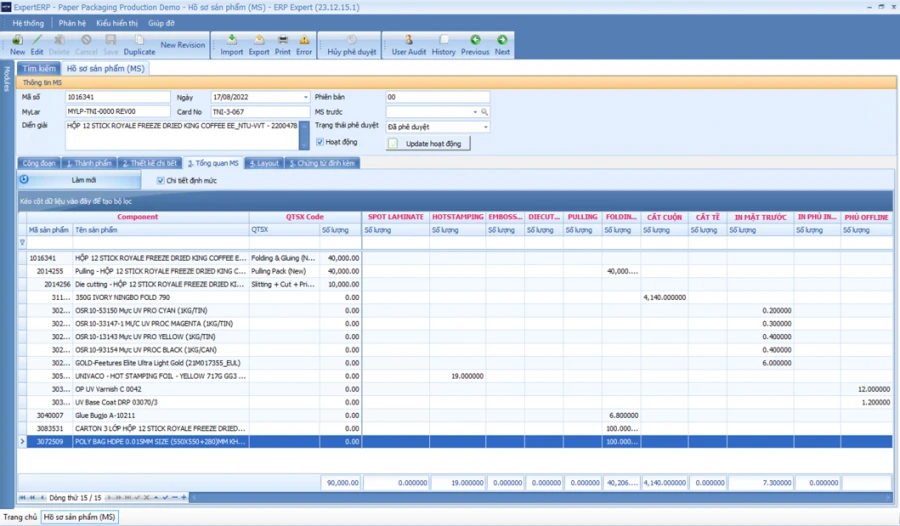

The software allows management:

Automatic calculation support system:

Automatic calculation system:

Ability:

Ability:

The software allows:

Ability:

Ability:

Ability:

Ability:

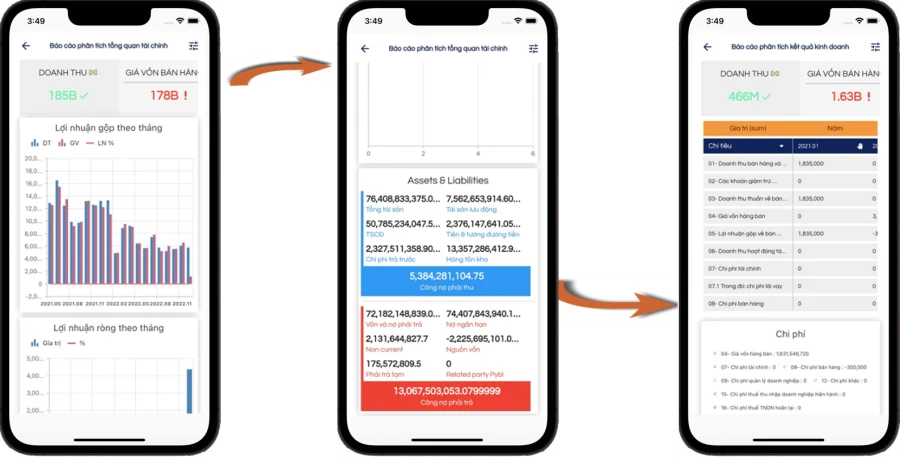

SMART REPORT

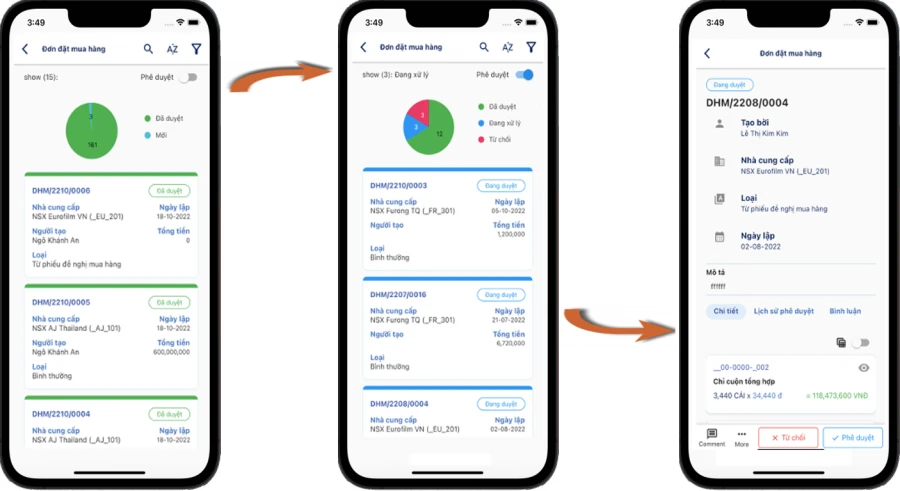

ORDER REVIEW

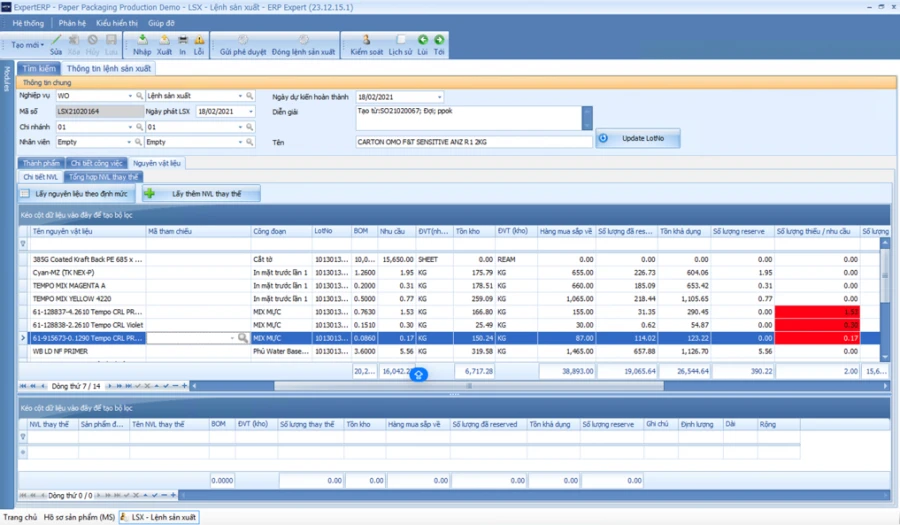

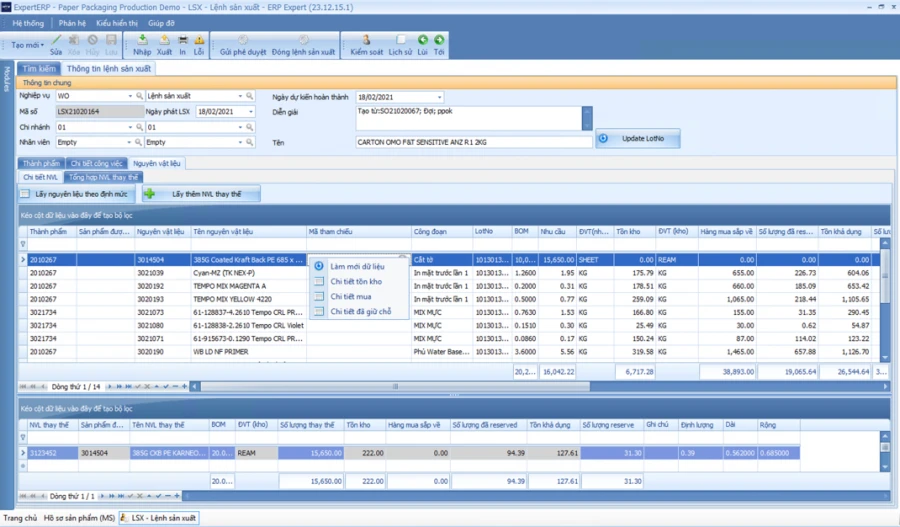

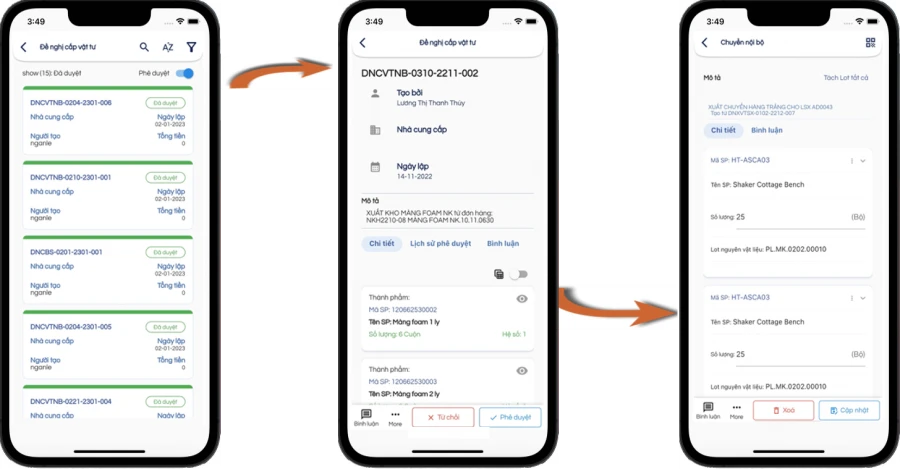

CONTROL OF PRODUCTION MATERIALS

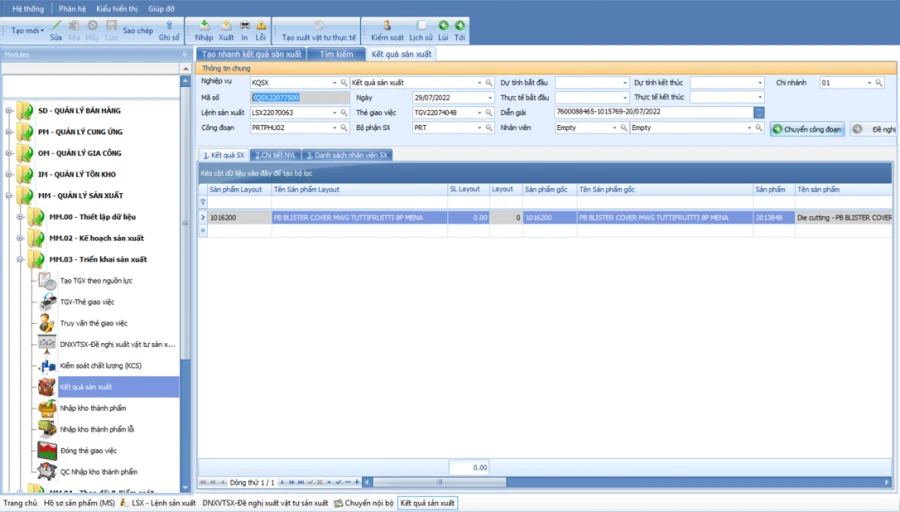

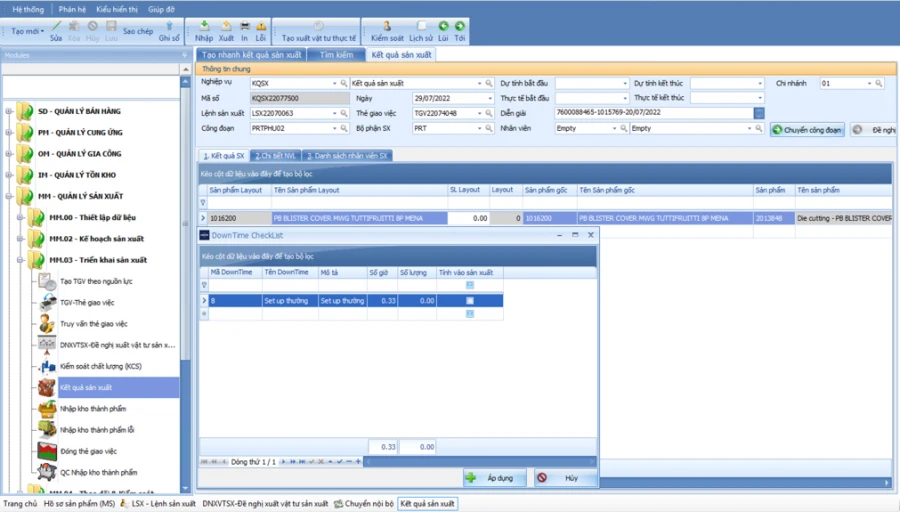

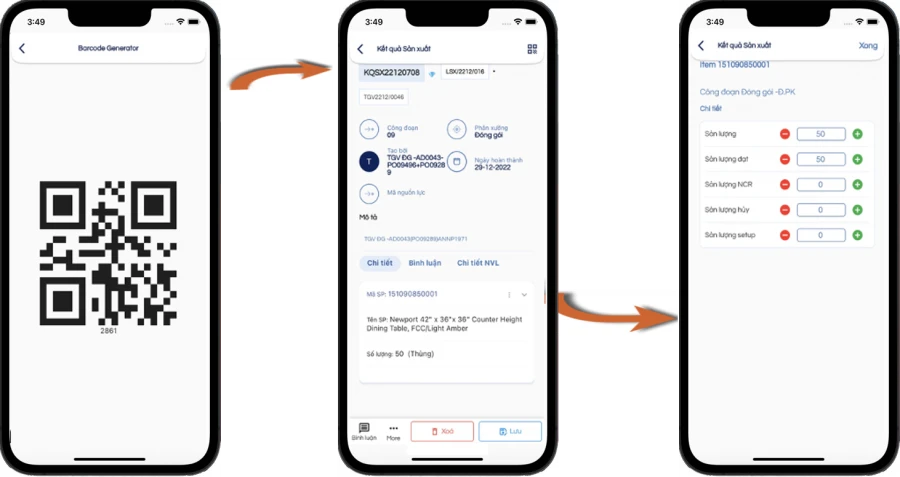

RECORD PRODUCTION RESULTS

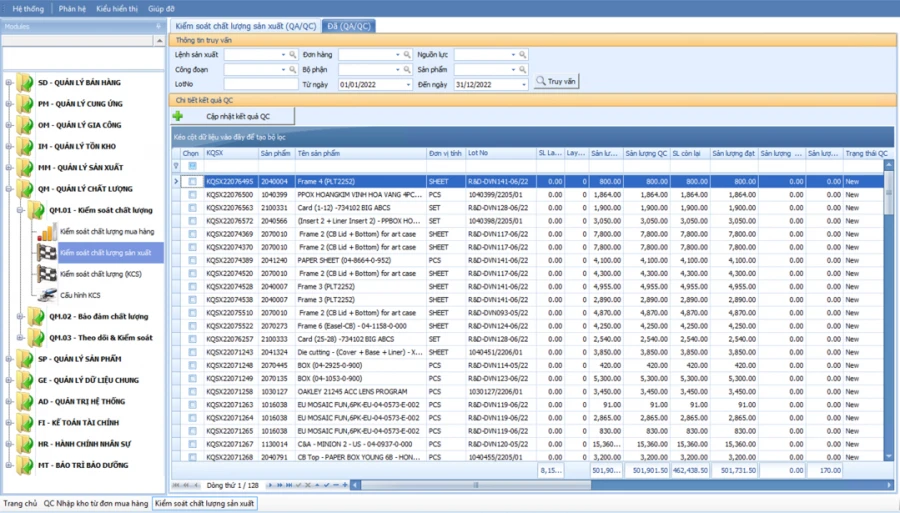

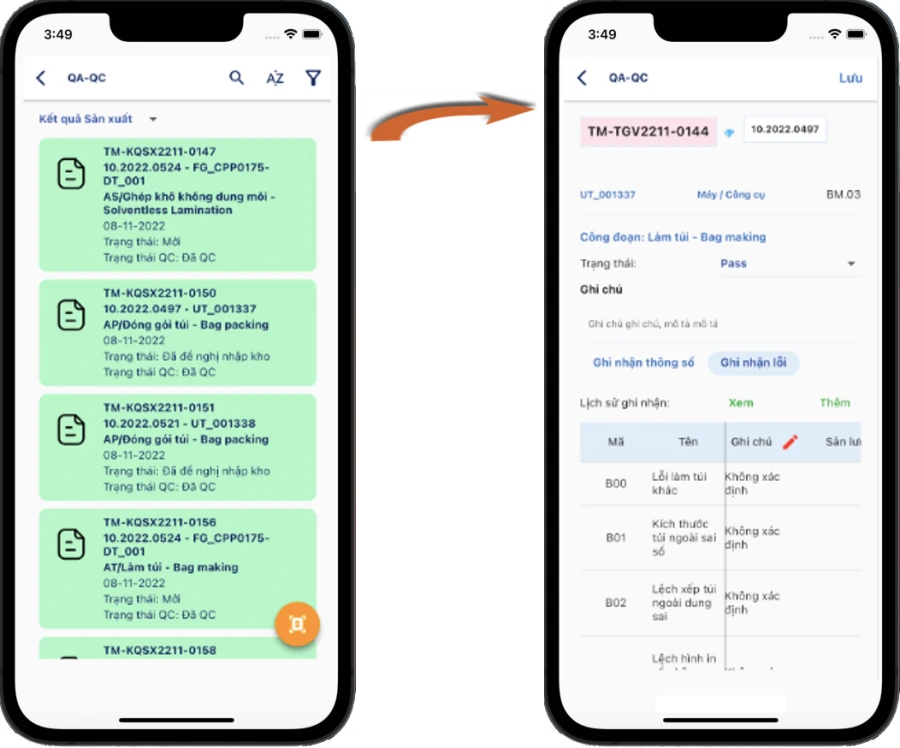

QUALITY ASSESSMENT BY LINE

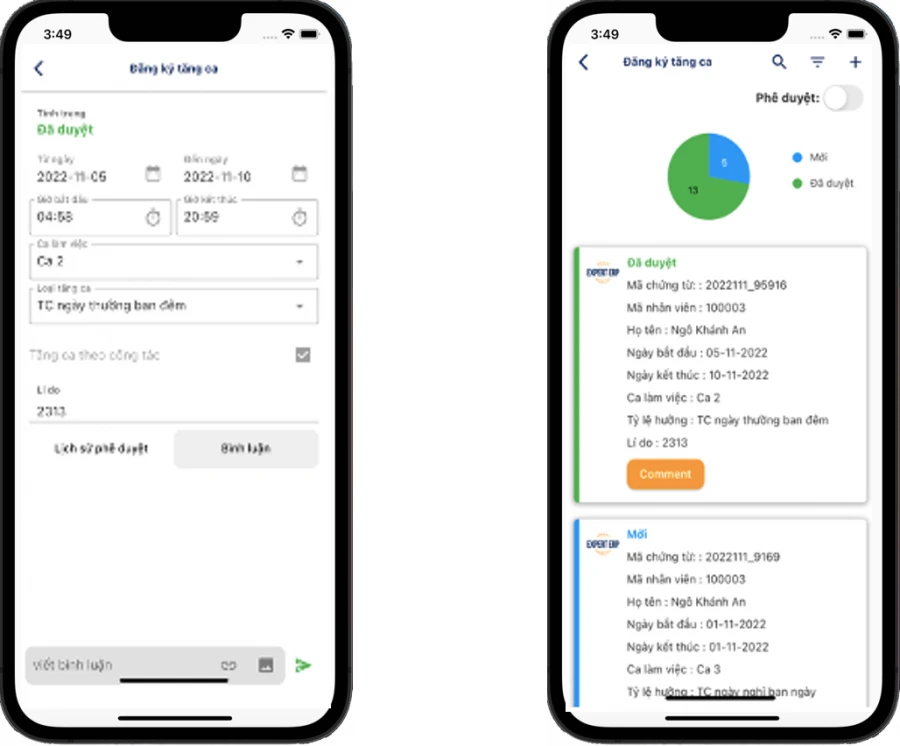

OVERTIME REGISTRATION

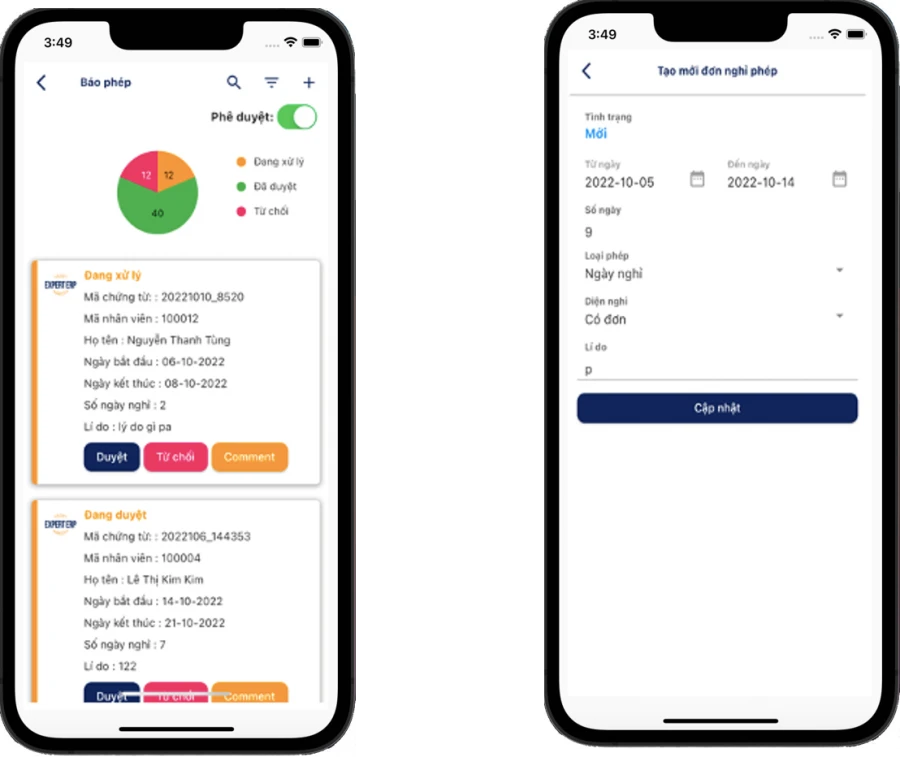

LEAVE REPORT

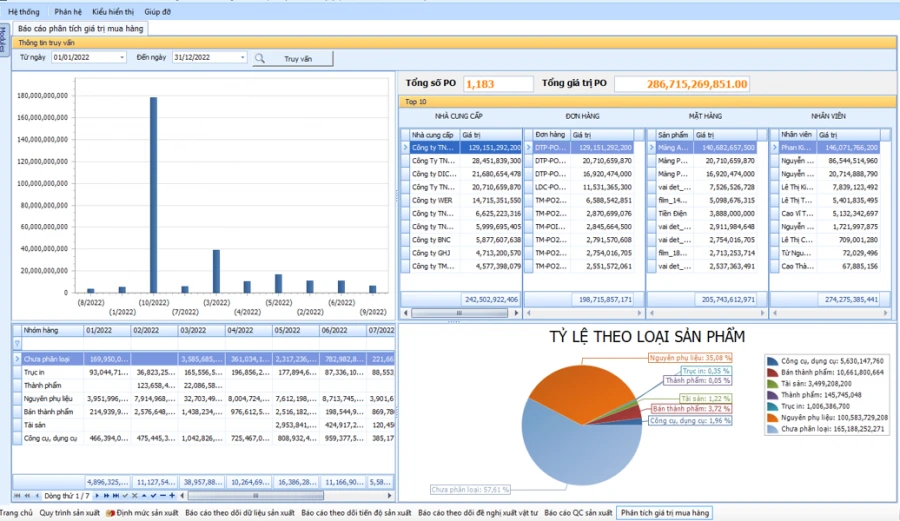

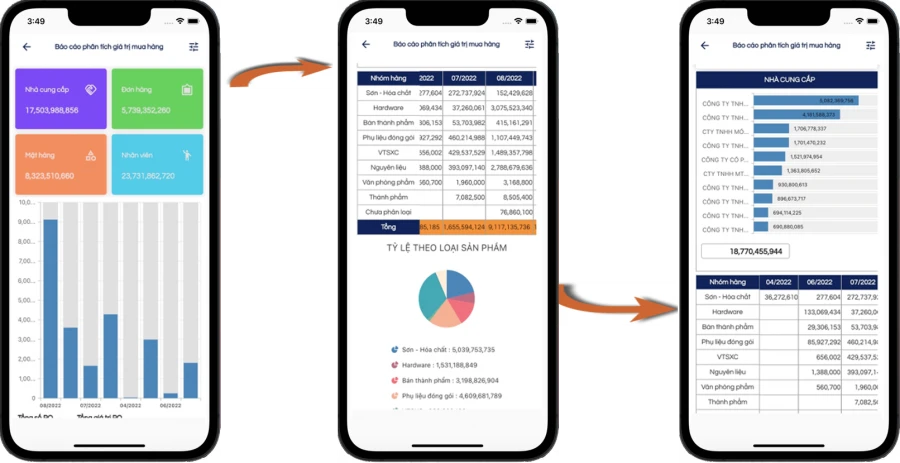

PURCHASE ANALYSIS

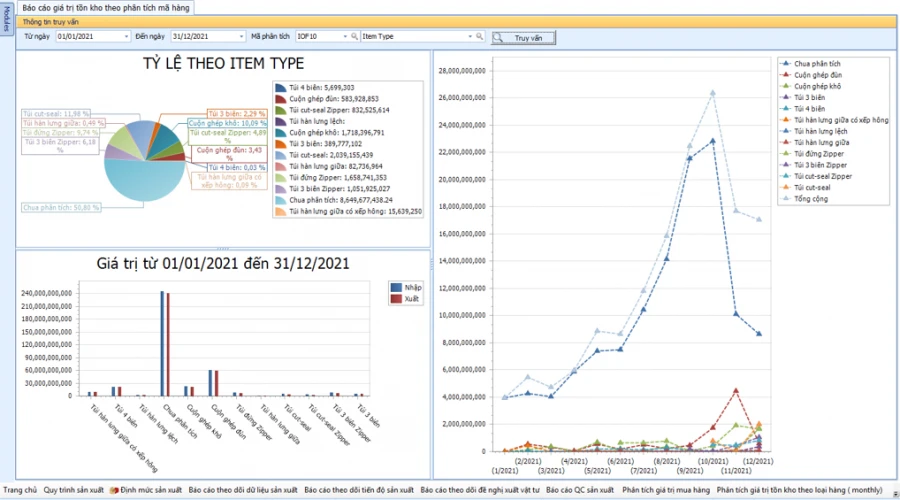

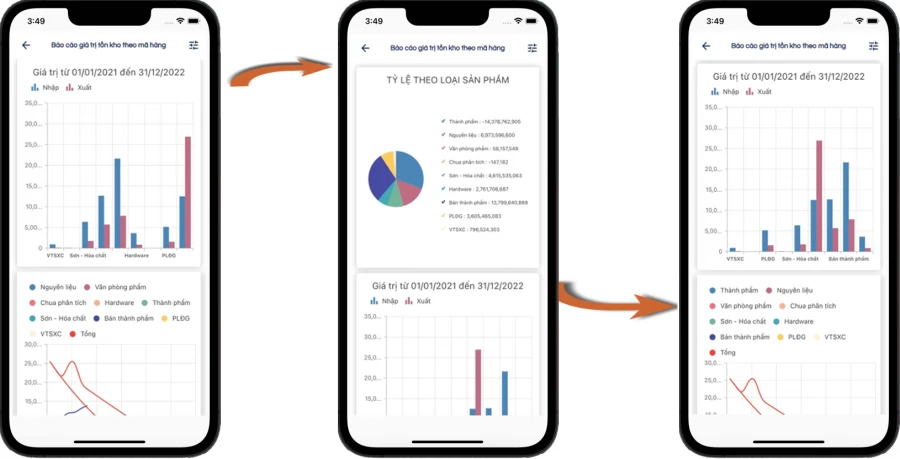

INVENTORY VALUE ANALYSIS

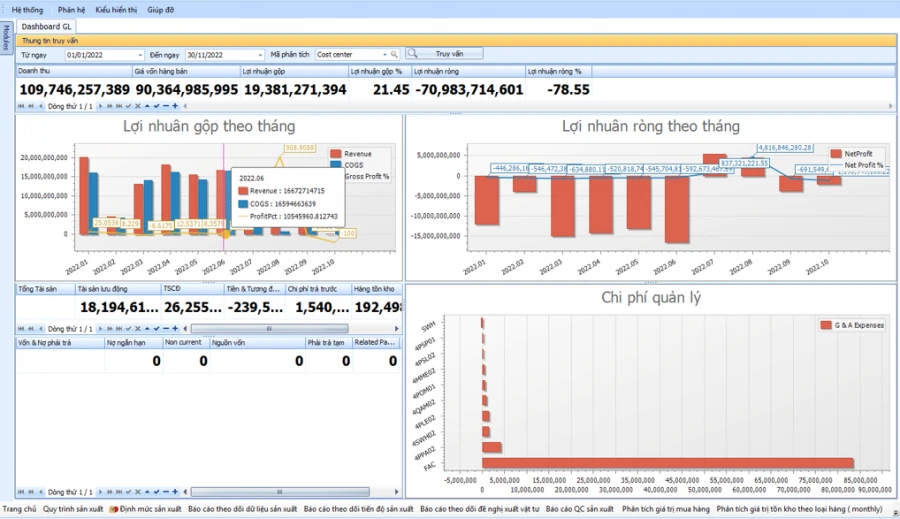

OVER VIEW OF FANANCIAL SITUATION