The wood processing industry and interior - exterior furniture manufacturing industry has a very ancient history of development, parallel to human development. Wood processing and producing wood products (carpentry) to serve human life and activities such as houses, tables and chairs, beds, cabinets, ... are traditional crafts of almost every ethnic group in the world.

However, along with the development of society and science and technology, wood processing and interior - exterior furniture have been industrialized, mass-produced in large quantities in factories, applying a series of machines from simple to complex. Craft carpentry is still there, but the main focus is on custom-made products that need the ingenuity, meticulousness, and creativity of the craftsman in the direction of the station, sculpture.

Despite being affected by the Covid-19 epidemic, in 2020, Vietnam surpassed Poland, Germany, and Italy, second only to China in the top of countries exporting wood and wood products in the world. In 2020, the export turnover of forest products reached 13.17 billion US dollars, up 16.4% over the same period in 2019. The export value of timber and forest products in the first 6 months of 2021 is estimated at 8.71 billion USD, an increase of 61.6% over the same period in 2020, the export value orientation of over 12 billion USD is completely feasible in 2021.

In the context that the global wood production and processing industry has many difficulties when the US - China trade war is increasingly tense, Vietnam's wood exports have a huge advantage. This is one of the few industries that has grown every year for the past 18 years despite the world economy in crisis, even with double-digit growth years, such as in 2019 and 2020 despite Covid-19. Vietnam is currently the fourth largest wood exporter in the world, the second largest in Asia. In 2019, exports reached 11.8 billion USD, in 2020 more than 12.5 billion USD.

However, this industry also has the following big challenges:

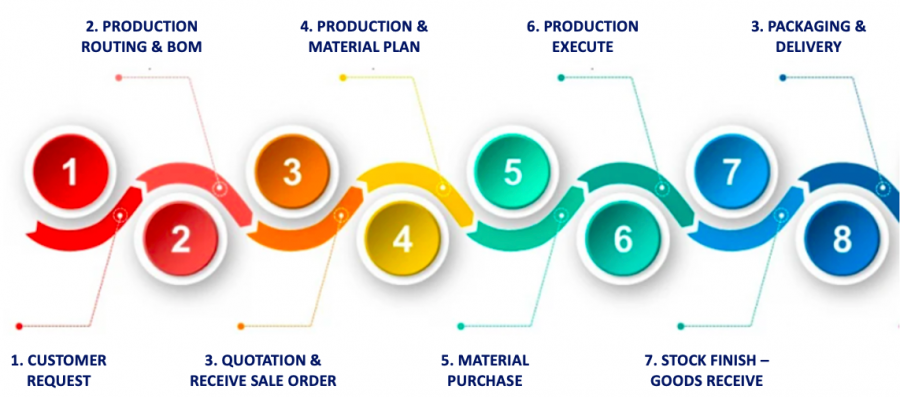

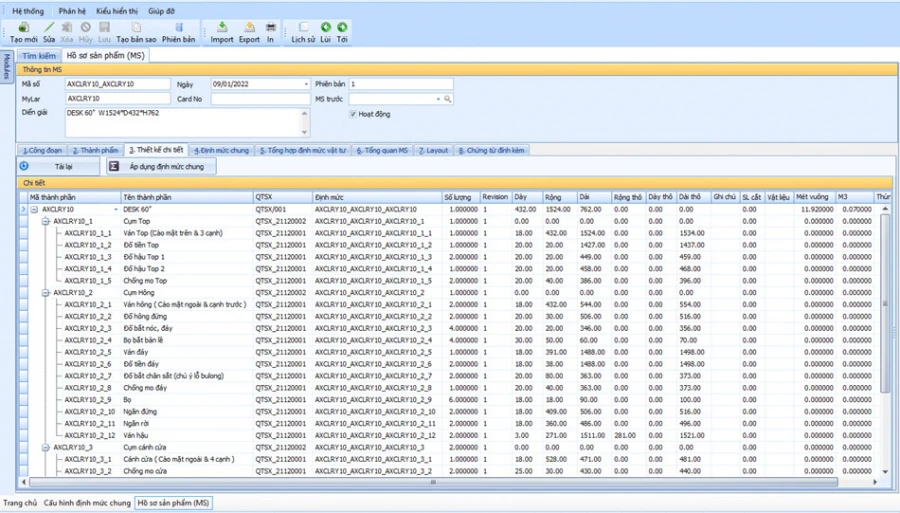

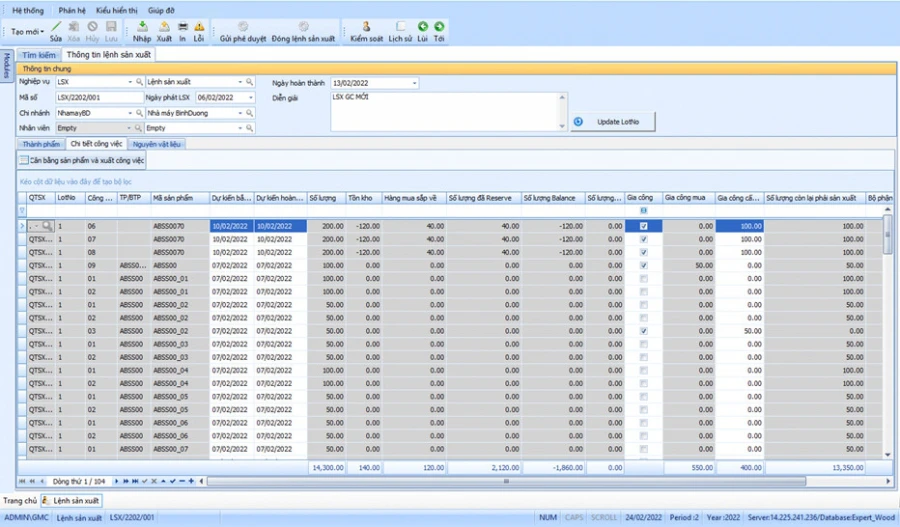

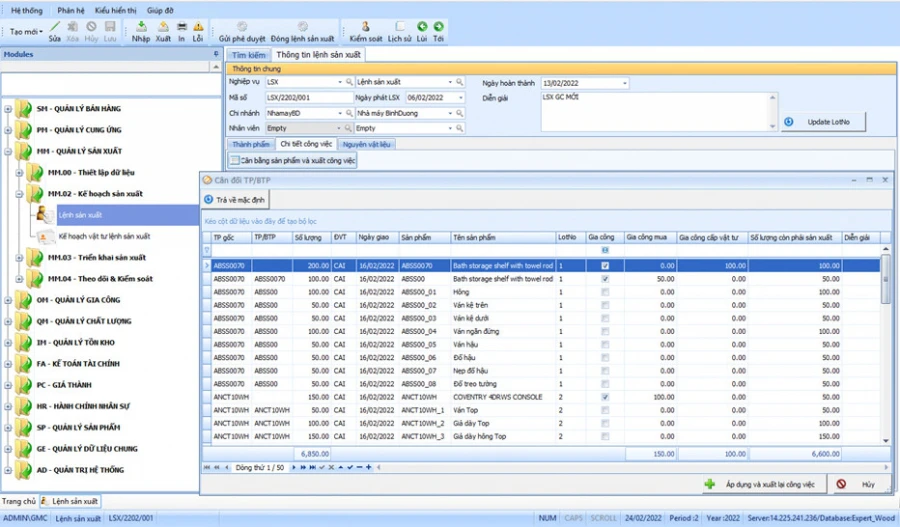

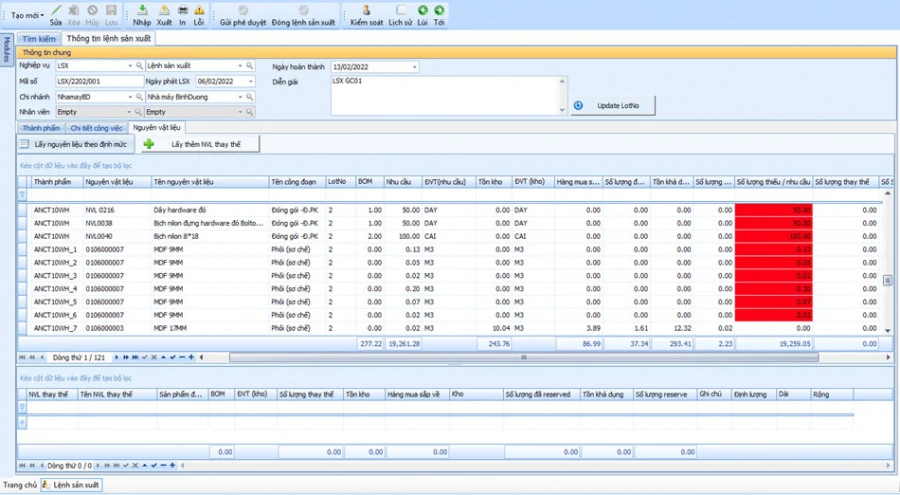

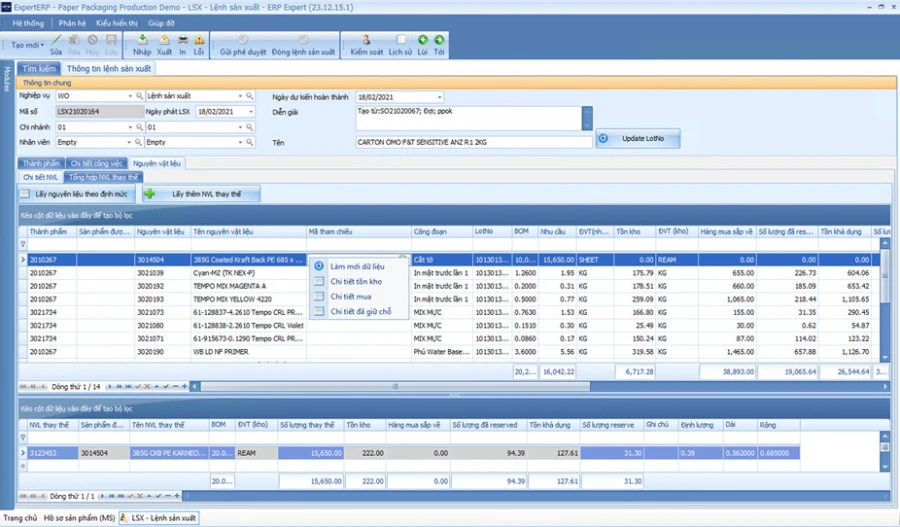

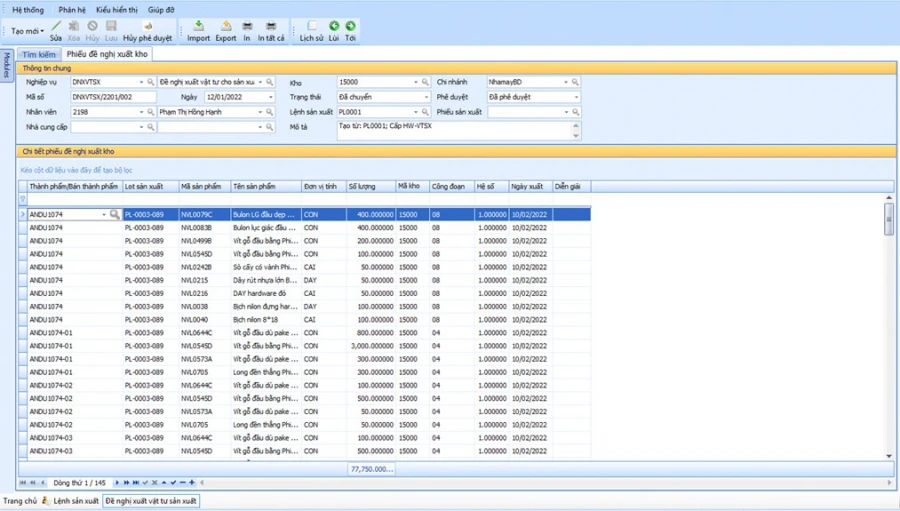

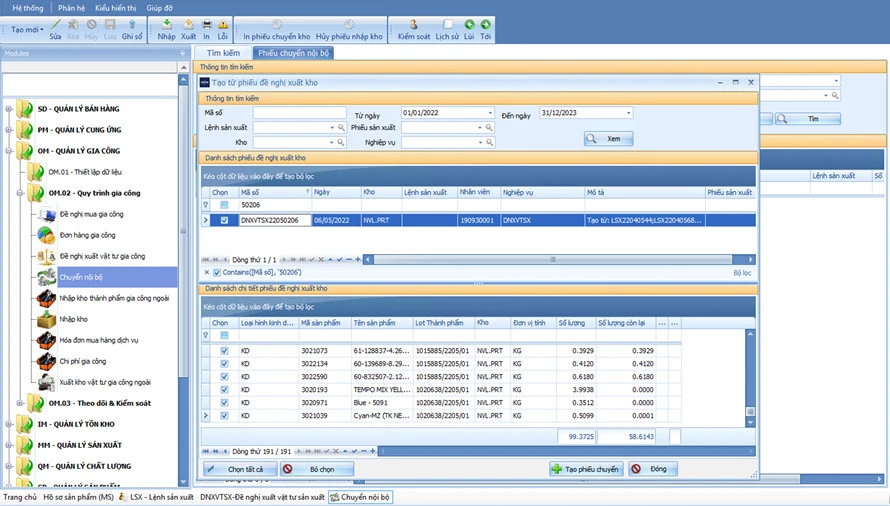

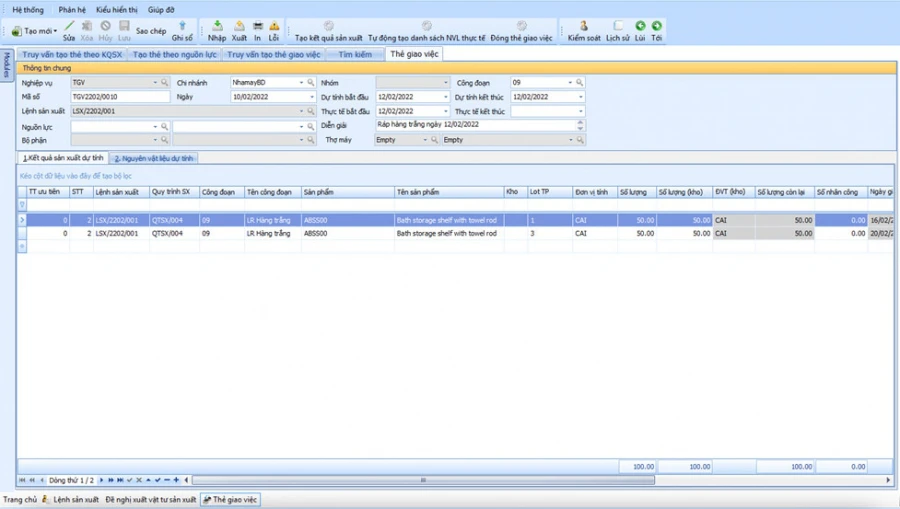

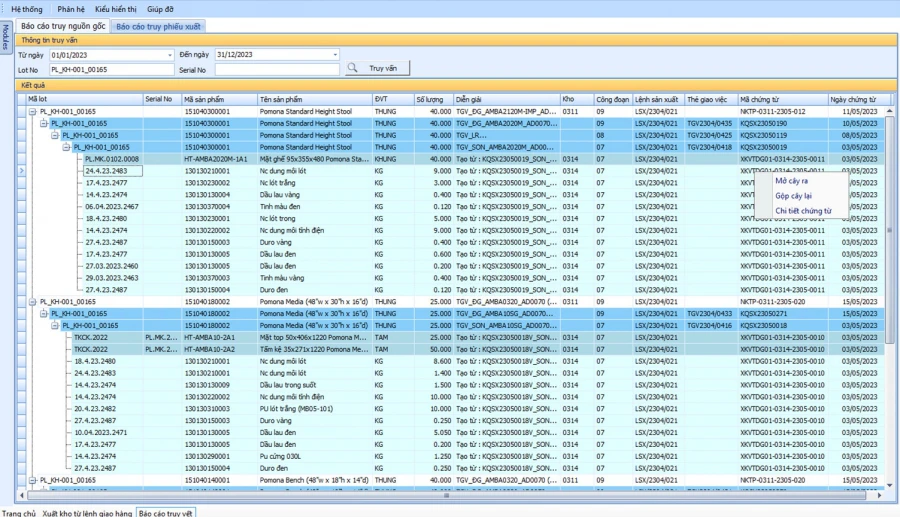

Enterprises in the wood and furniture industry mainly produce according to Orders/Consts, so the monitoring process from the Business stage - Production planning - Preparation of production materials - Production statistics - Warehouse of semi-finished products must be attached to Orders/Cons contracts. Therefore, businesses face difficulties in the planning stage, importing raw materials, machinery and equipment according to the "Just In Time" principle.

For Sales Department:

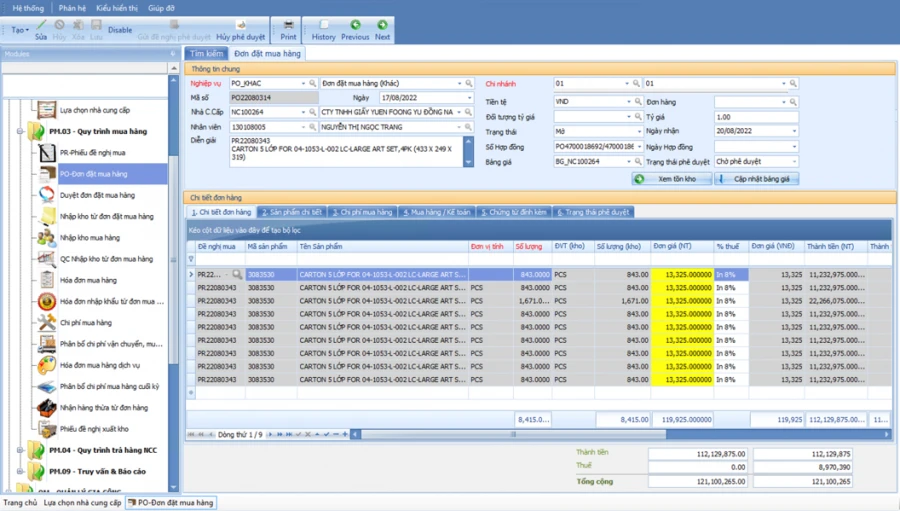

For the Purchasing Department:

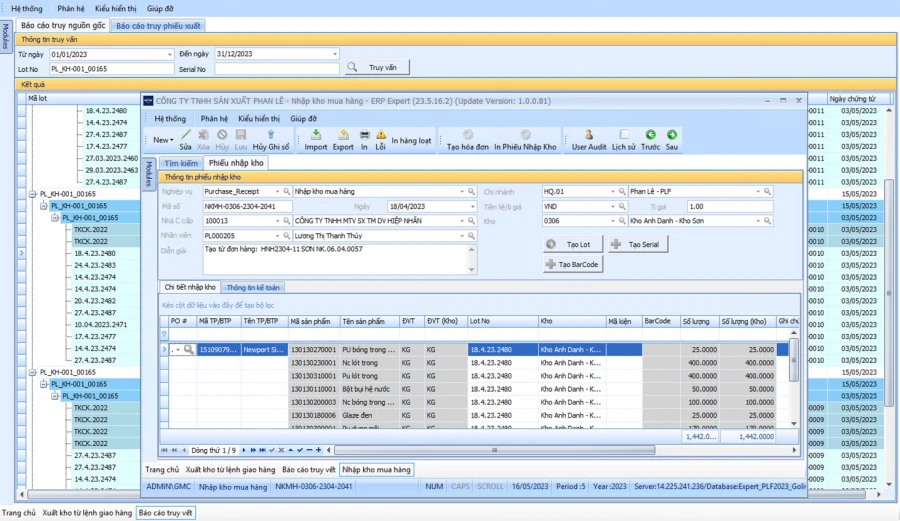

For Warehouse Management:

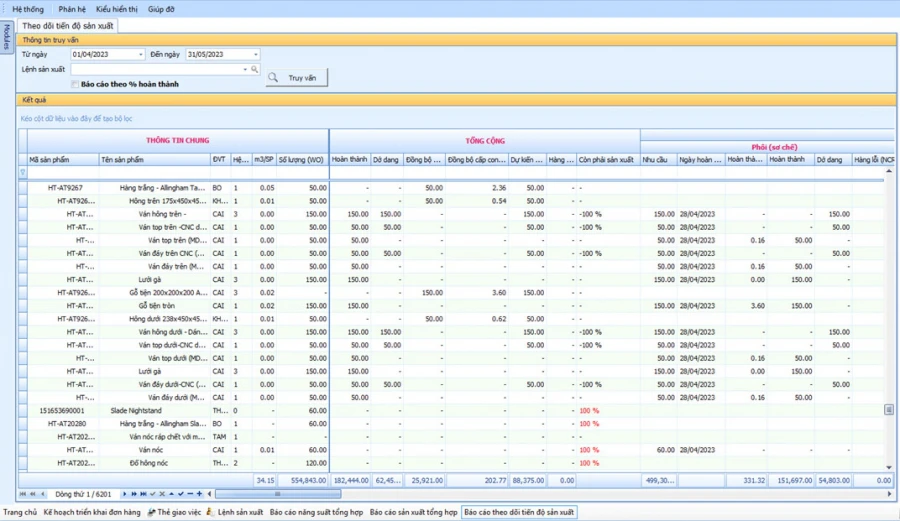

For Production Management:

For Machine and Equipment Management:

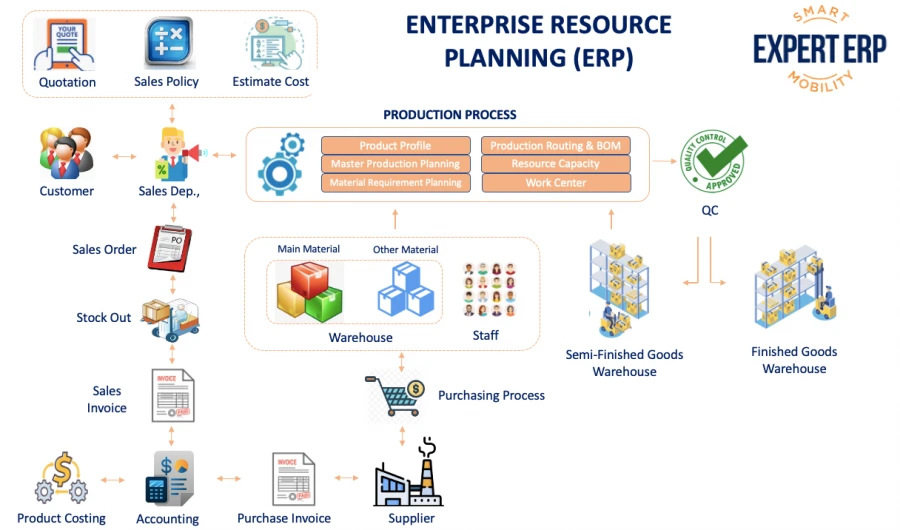

With in-depth knowledge and experience in research, analysis and development of Enterprise Resource Planning (ERP) Solutions in Europe. We build ExpertERP Solutions according to advanced technology, international standards with a process that both meets the multidisciplinary direction and can solve specific problems and intensive management requirements by industry.

With a team of experienced experts, successfully deployed for pharmaceutical manufacturing businesses in Vietnam. ExpertERP Total Management Solution applies to all business - production activities of enterprises, thanks to the application on a single platform of systems, software and databases, the flow of information data ensures transparency, seamless, instant, accurate. Allow access to data and statistics, instant reports, "Anytime - Anywhere - On any device", support the Leadership to make timely and correct decisions.

The Covid 19 pandemic situation will continue to have a bad impact and cause many difficulties for production - business activities of enterprises in general, the wood processing and furniture industries in particular. However, this is a favorable time for businesses to stabilize, re-regulate all activities, and move towards a comprehensive "DIGITAL TRANSFORMATION" of the company. If you want to be highly capable of improving management, increasing labor productivity, and increasing profit margins, you must digitize all core activities of the enterprise, which is the Application of ENTERPRISE RESOURCE PLANNING (ERP) SOLUTION. With successful deployment experience for many businesses in the industry, GMC's ExpertERP Solution will help your business achieve these key goals.

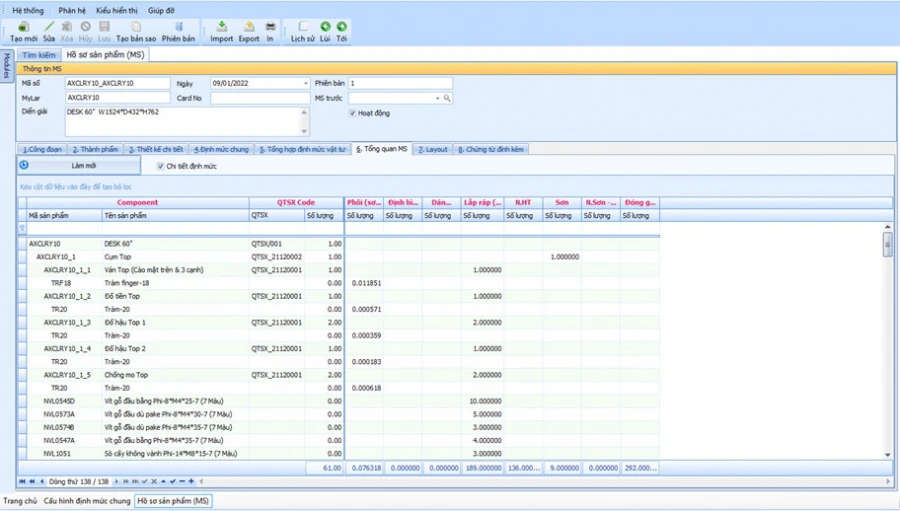

Allow to manage multiple revisions:

Automatic calculation system:

Ability:

Ability:

Ability:

Ability:

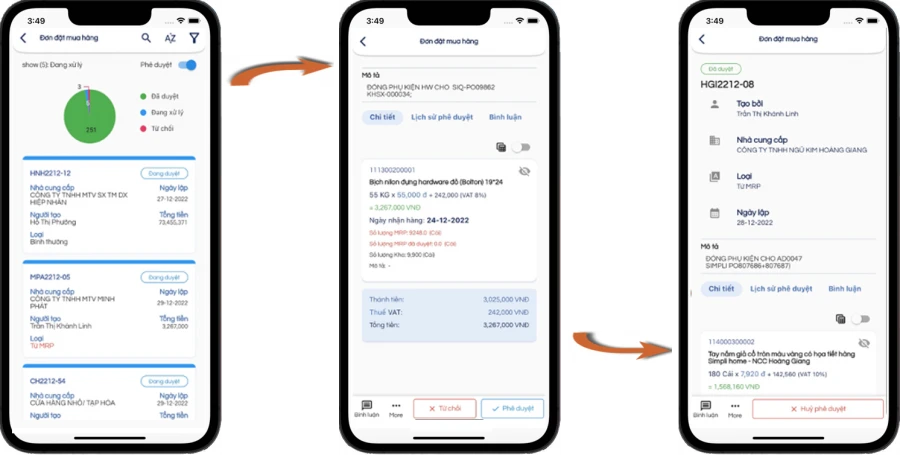

ORDER REVIEW

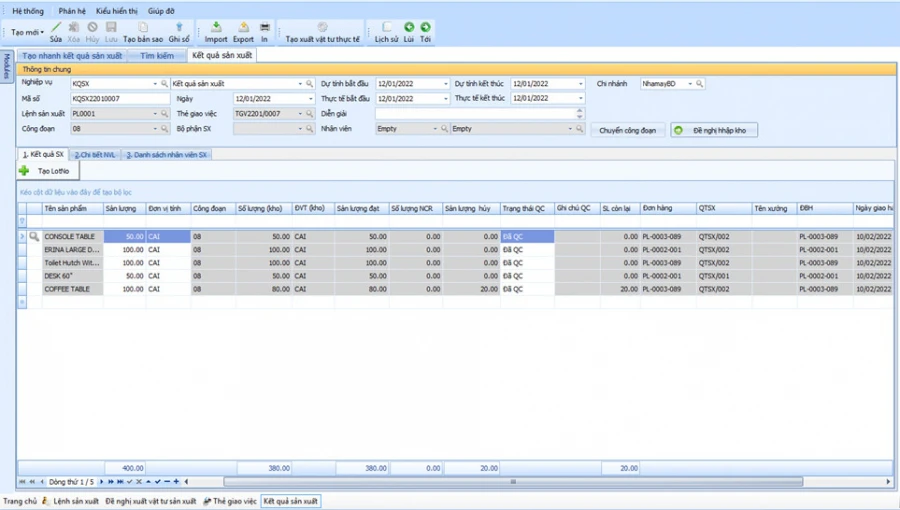

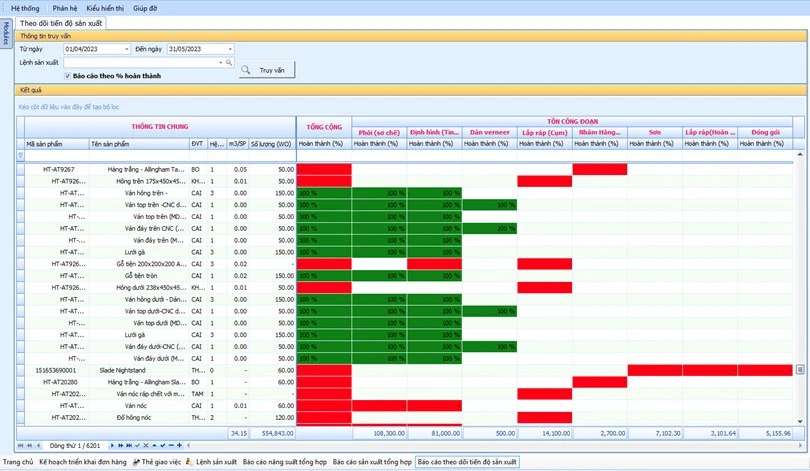

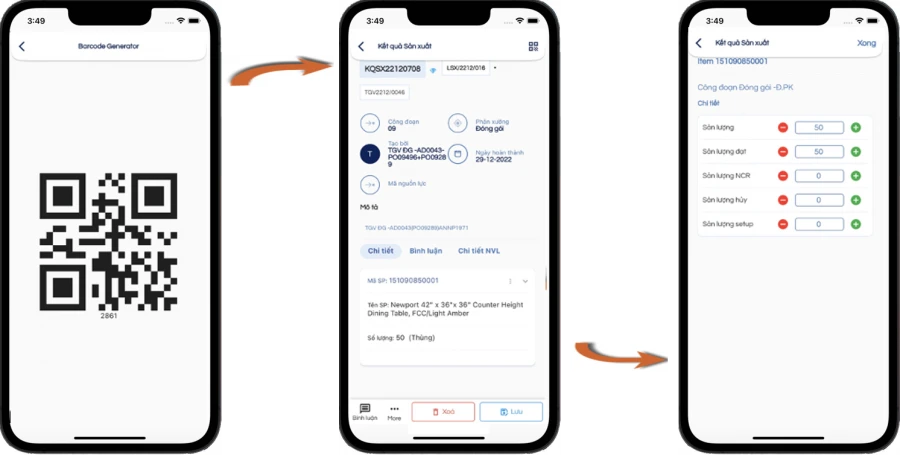

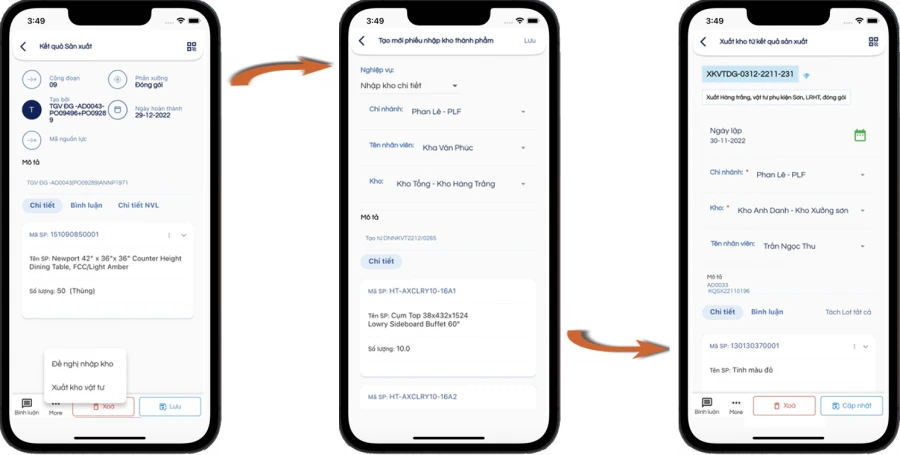

RECORD PRODUCTION RESULTS

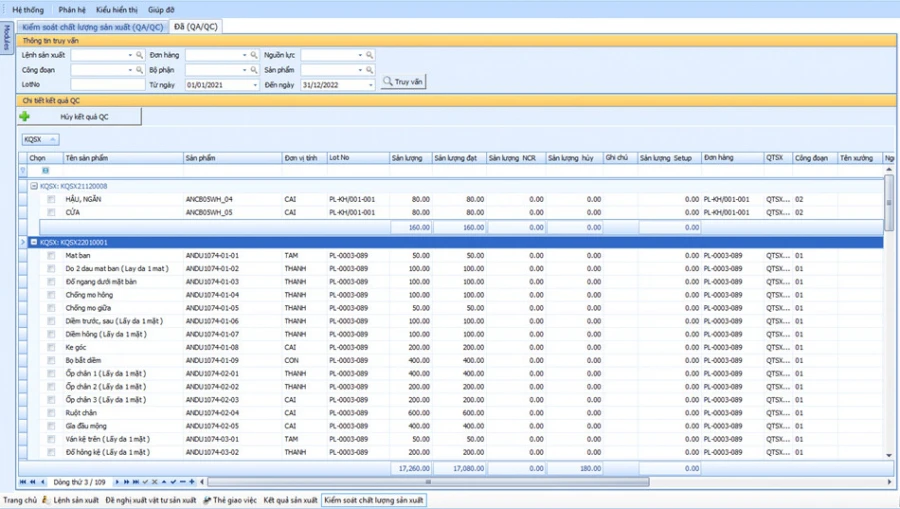

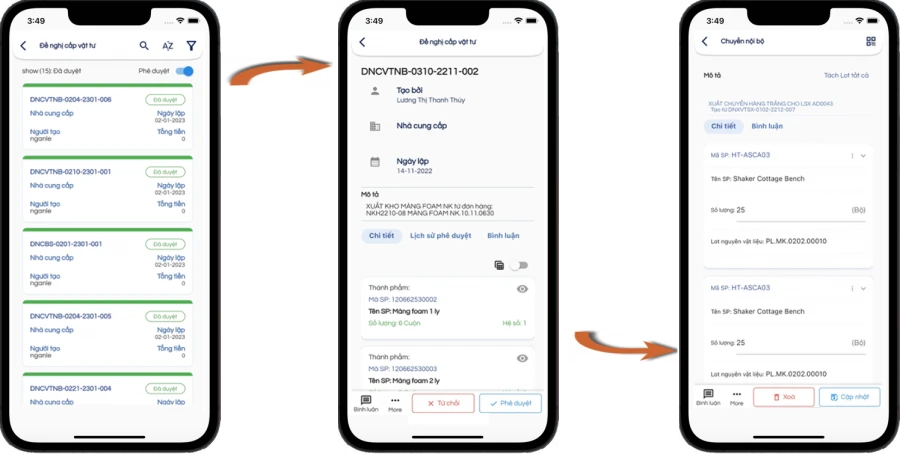

PRODUCTION MATERIAL CONTROL

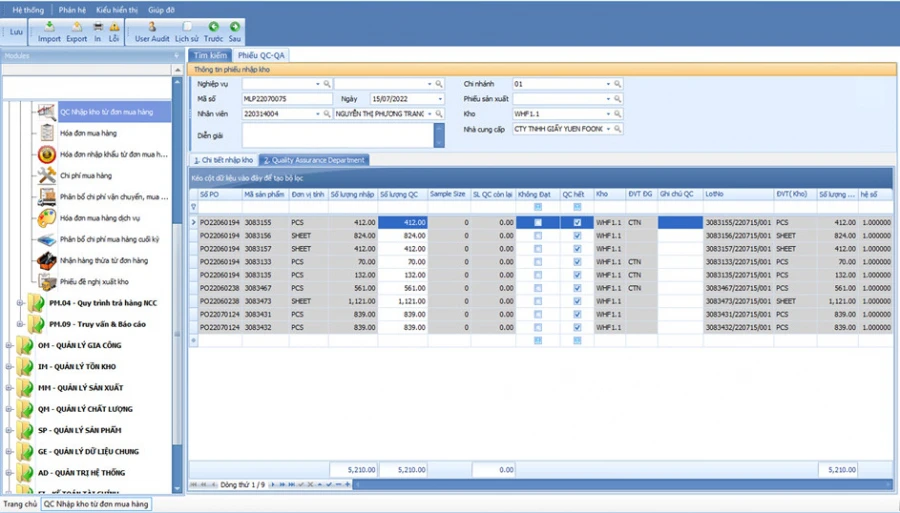

FINISHED PRODUCT WAREHOUSING & CONSUMPTION EXPORT

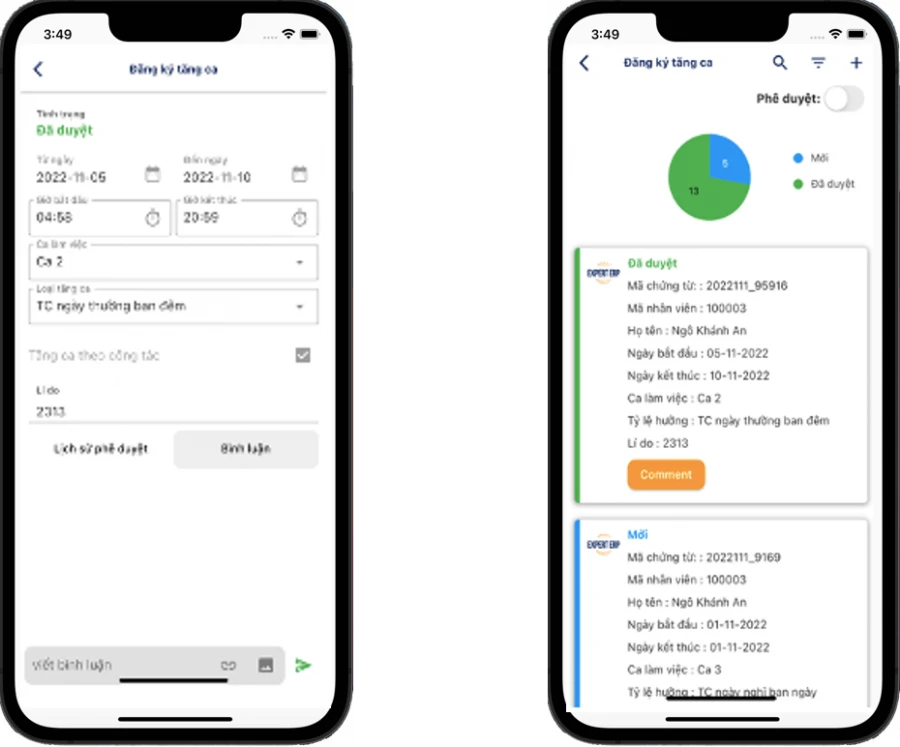

OVERTIME REGISTRATION

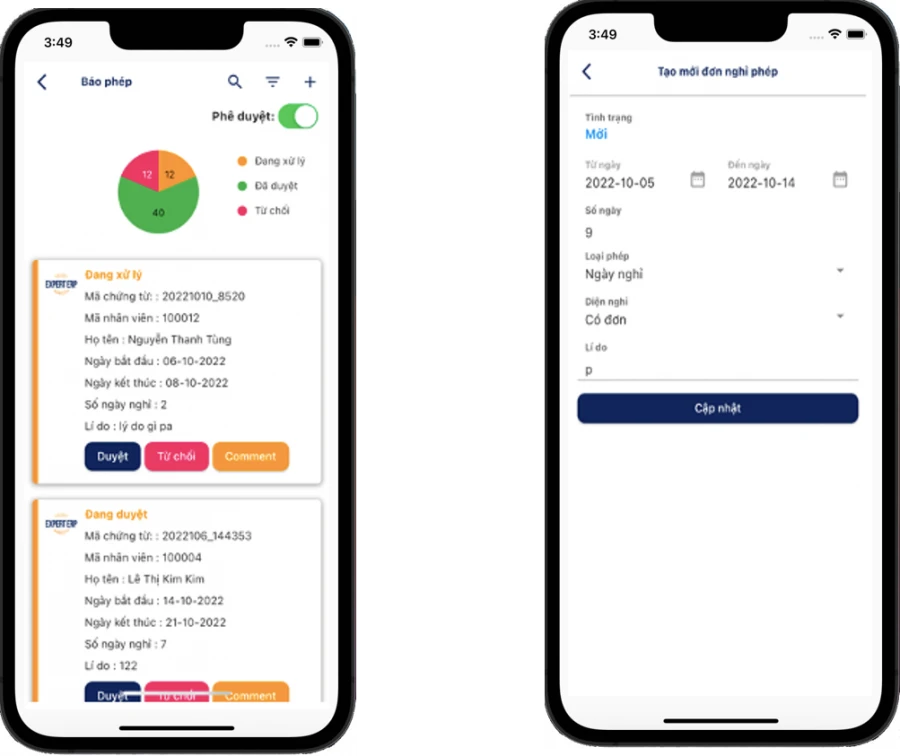

LEAVE REPORT

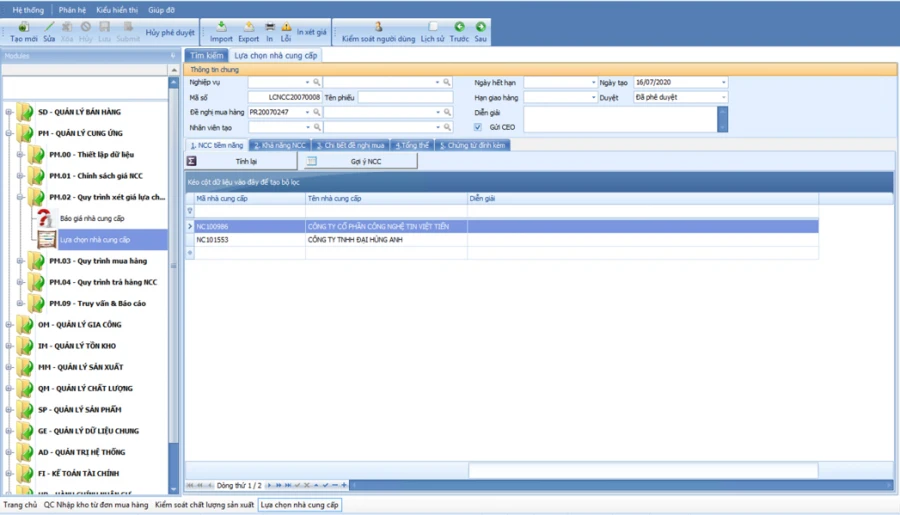

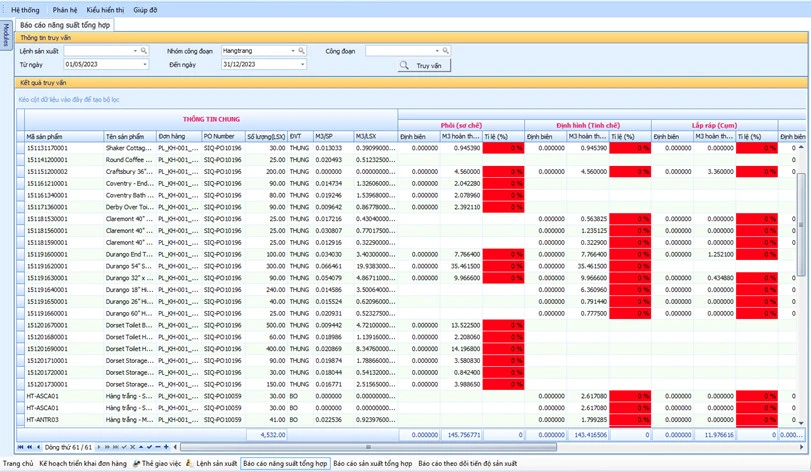

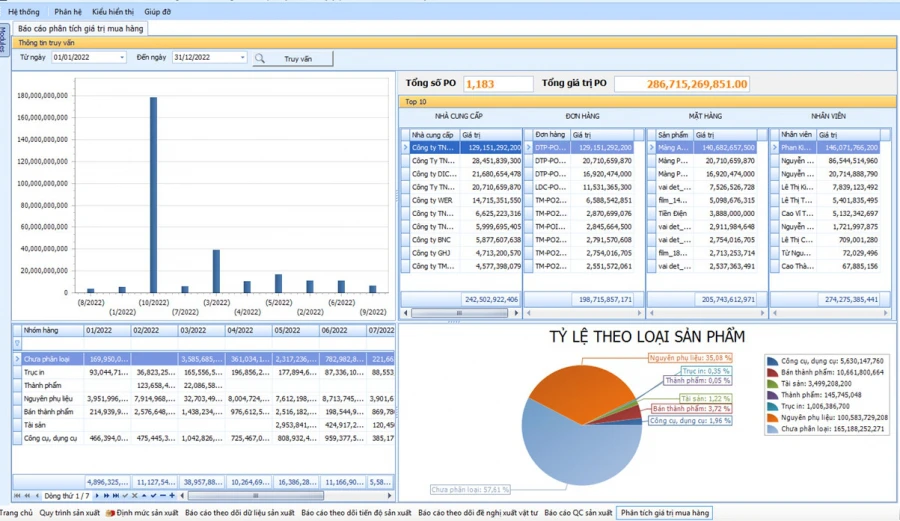

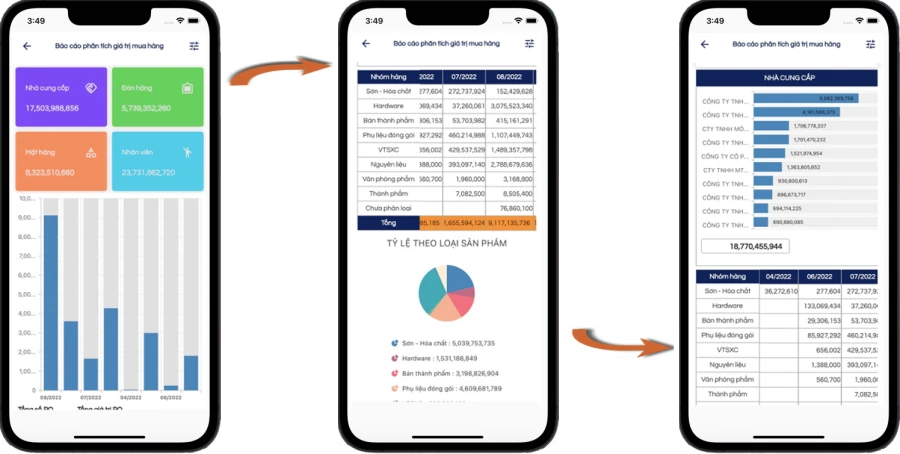

PURCHASE ANALYSIS

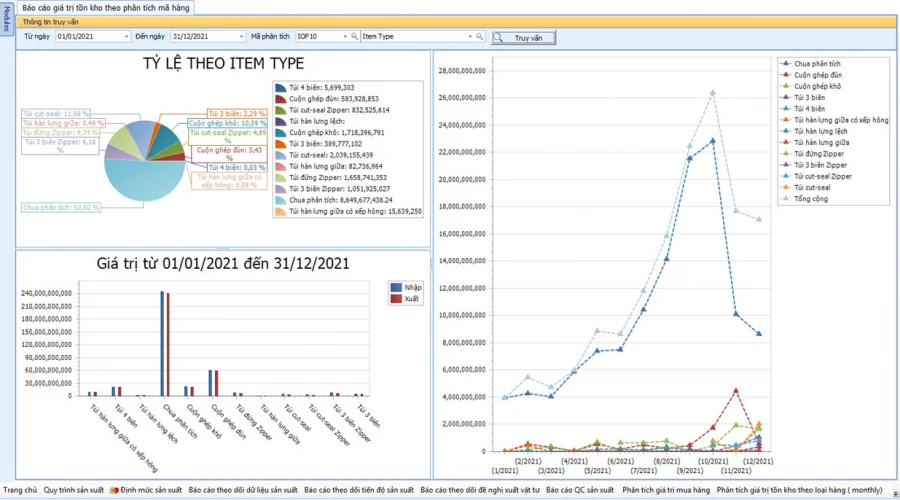

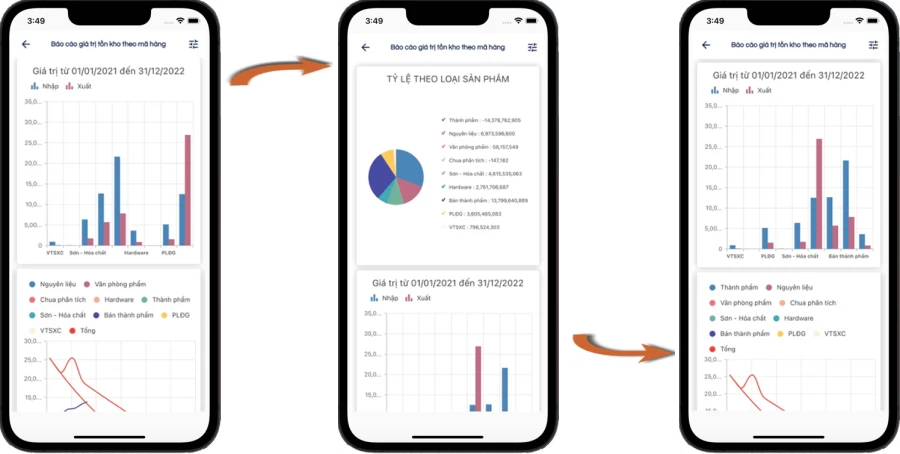

INVENTORY VALUE ANALYSIS

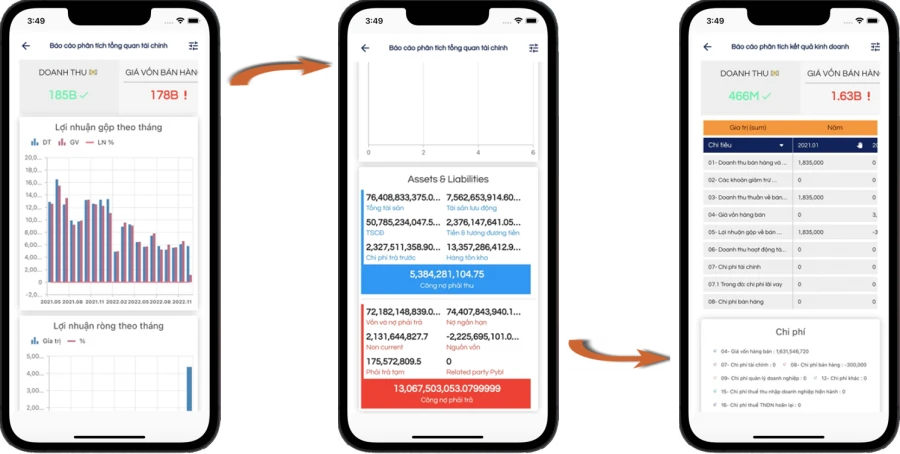

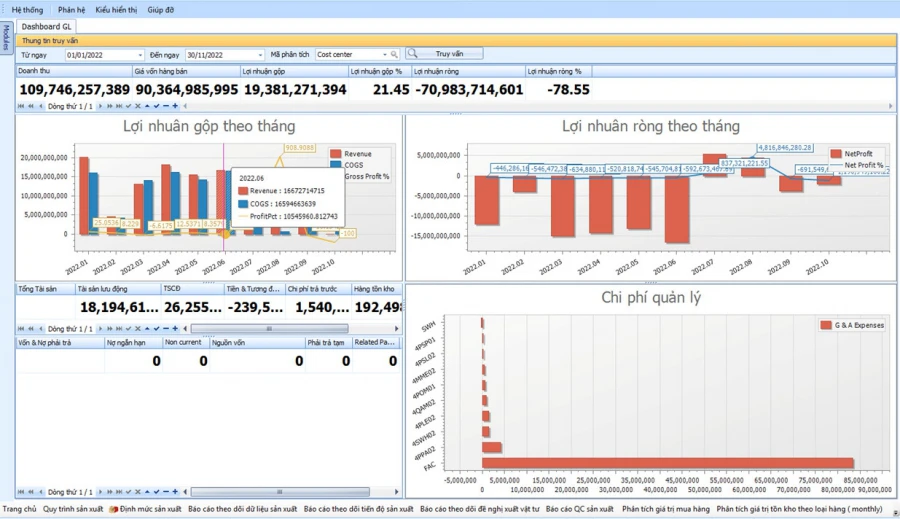

OVERVIEW OF FINANCIAL SITUATION