Plastic packaging is produced from plastic (plastic) which is a type of artificial substance. The characteristics of plastic packaging are light, waterproof and quite durable. Currently, to create safe plastic packaging, people use a variety of pure plastic particles refined from kerosene. Currently, there are plastic granules as follows: PE (Polyethylene); PP (Polyrpopylene); PVC (Polyvinylchloride); PC (Polycarbonate); PET (Polyethylene terephthalate).

There are 02 most popular types of plastic packaging today, which are plastic packaging and complex screen packaging.

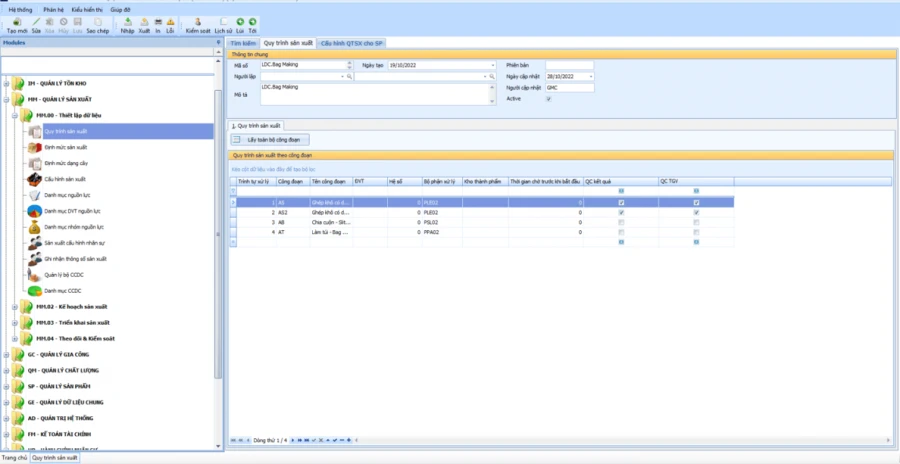

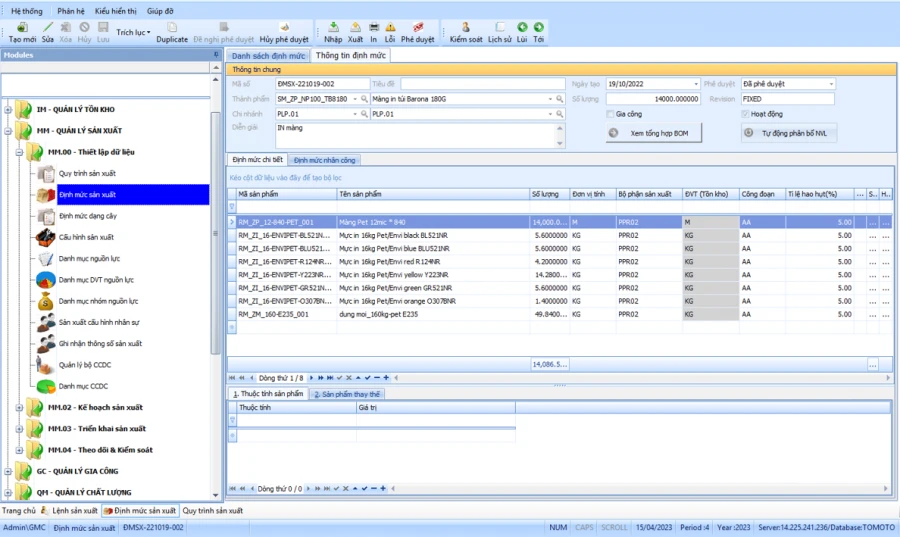

PRODUCTION PROCESS

According to the activity report of the Vietnam Plastics Association, in 2020, the revenue of the plastic industry reached 17.58 billion USD, still maintaining the growth in export turnover, in which plastic bag products were exported the most, accounting for 26.7% of total export turnover and reaching 894 million USD.

For the world market, the value of the global packaging industry reaches about 424 billion USD. In which, the Asian packaging industry accounts for 27%, Europe 30% and North America 28% (According to the market research report of SPG Media Group in 2020)

In the future, soft packaging is considered to develop more strongly thanks to the progress of materials. Currently, most soft packaging uses materials made of Polyethylene (PE); Polyethylene terephthalate (PET) or Polypropylene (PP) which are highly durable to use and safe for food, do not cause poisoning and infection of food.

However, plastic packaging and paper packaging businesses all face common difficulties under the impact of the Covid-19 pandemic. Research results from the survey of businesses in the field of packaging of Vietnam Report have pointed out 4 difficulties, which are:

Paper packaging enterprises mainly produce according to Orders/Contricts, so the monitoring process from the Business stage - Production planning - Preparation of production materials - Production statistics - Warehouse of semi-finished products-finished products must be attached to Orders/Cons. Therefore, businesses face difficulties in the planning stage, importing raw materials, machinery and equipment according to the "Just In Time" principle.

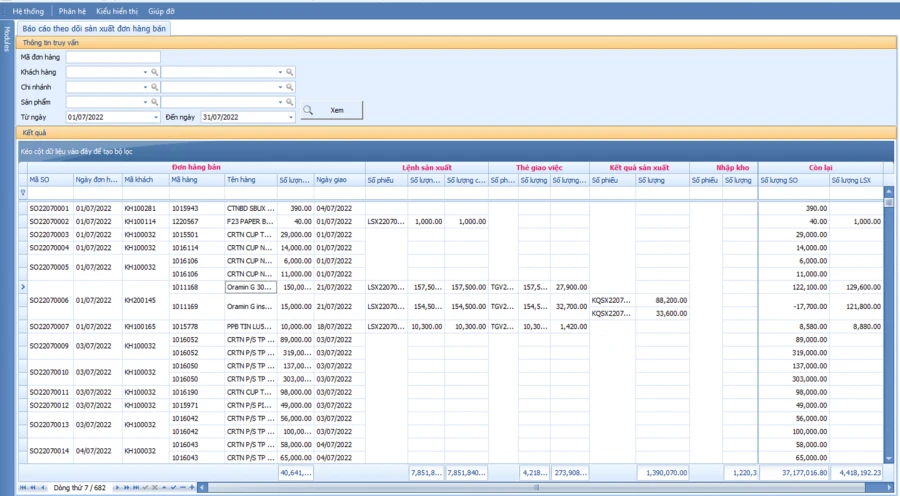

For Sales Department:

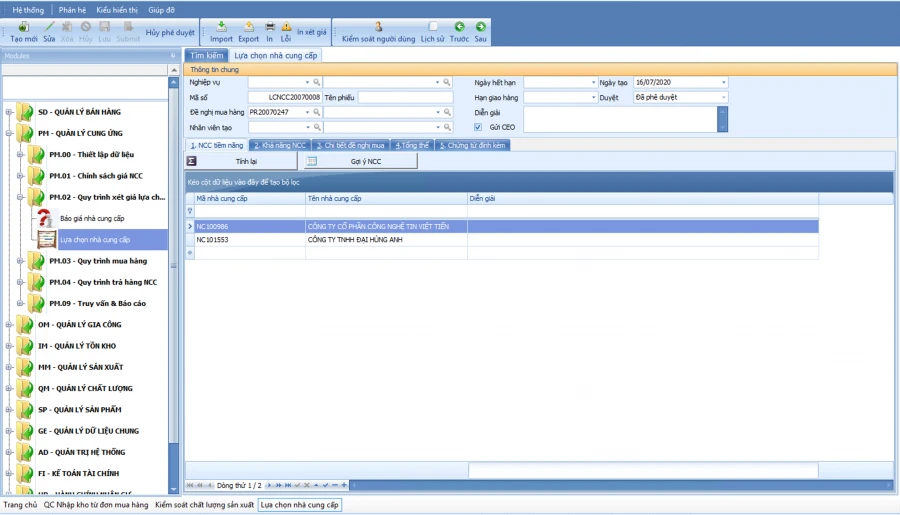

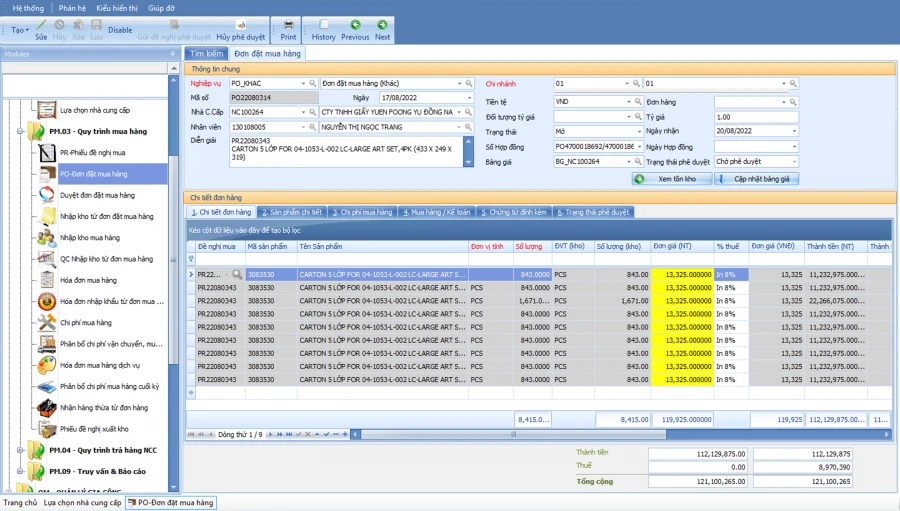

For the Purchasing Department:

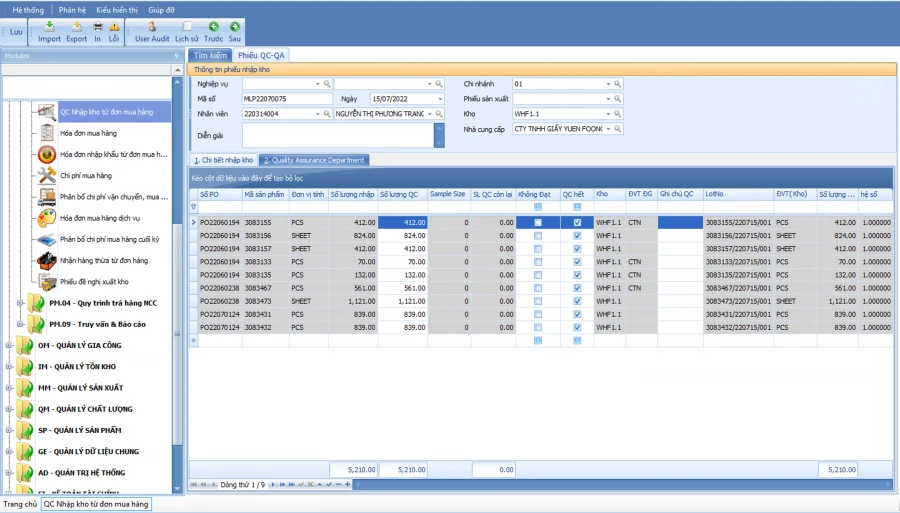

For Warehouse Management:

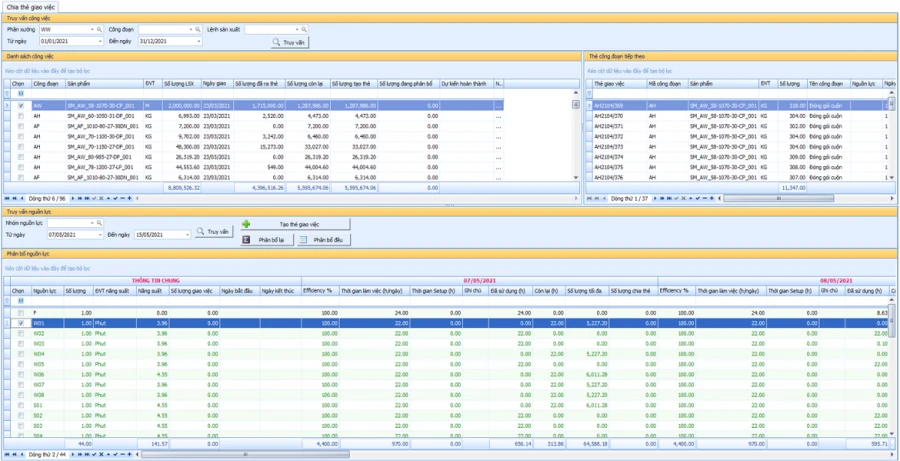

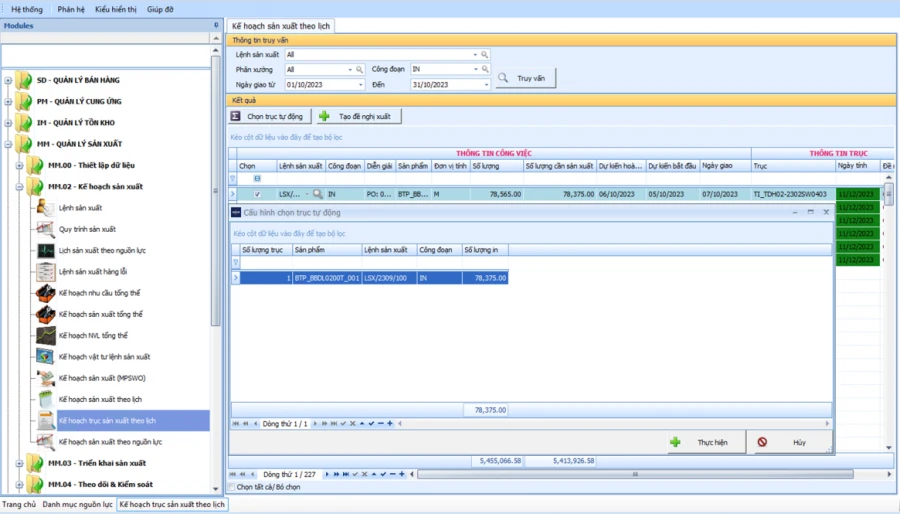

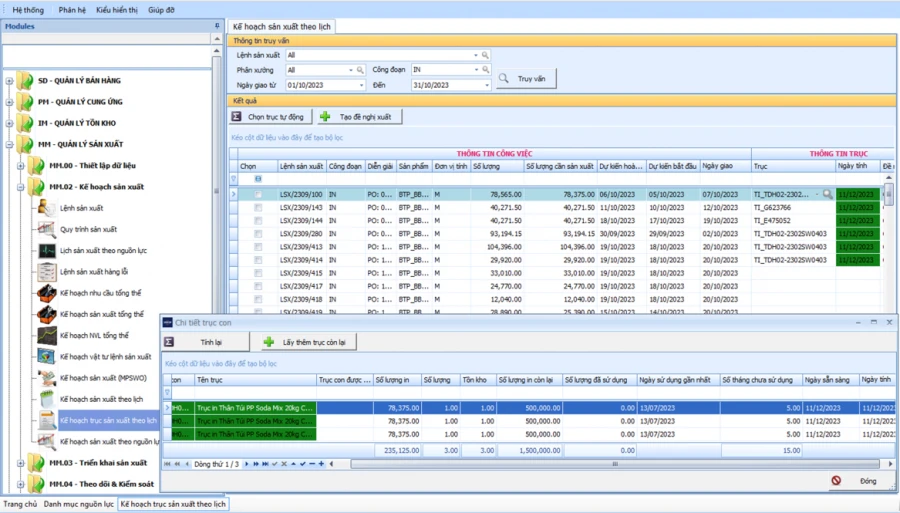

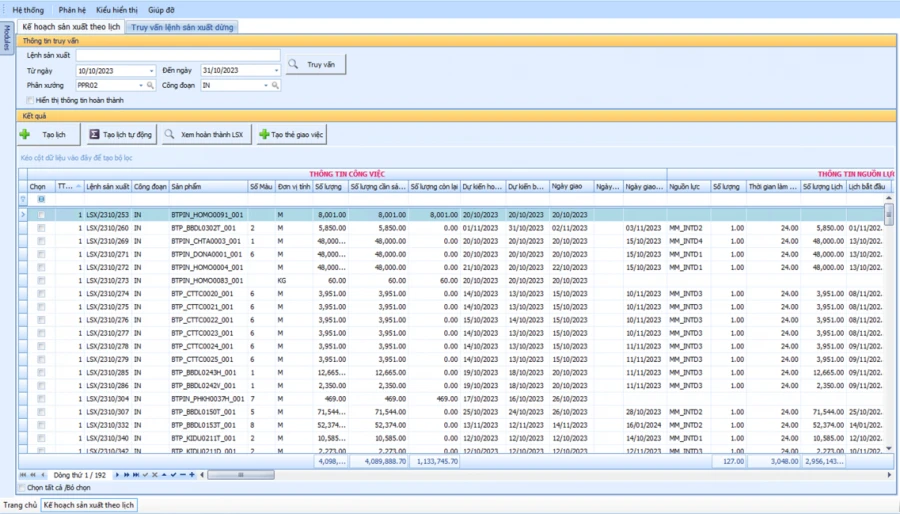

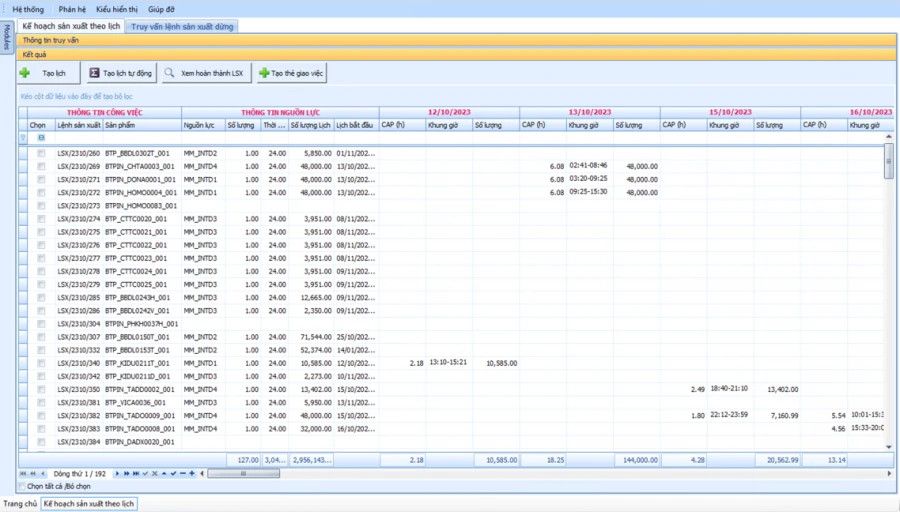

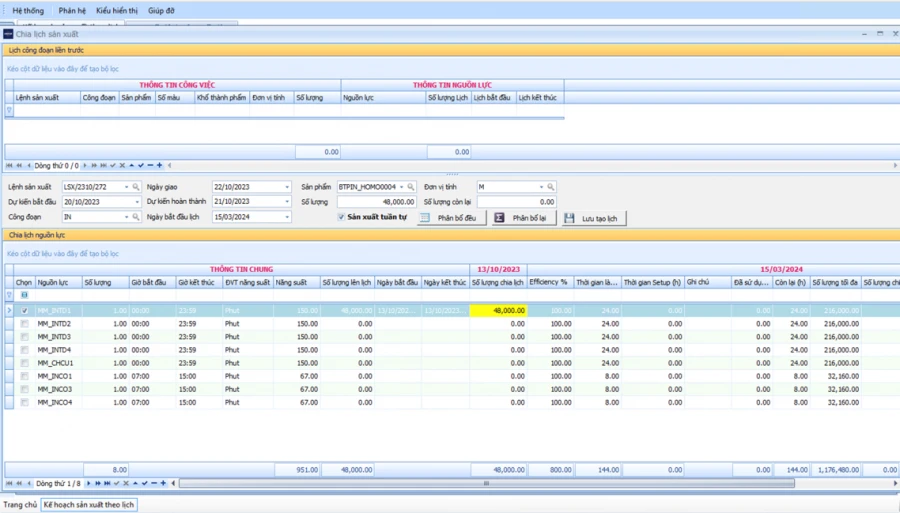

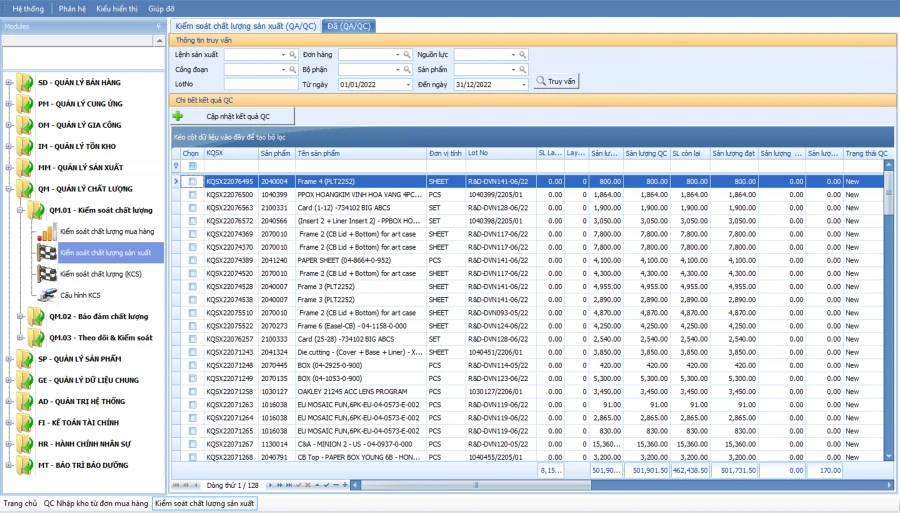

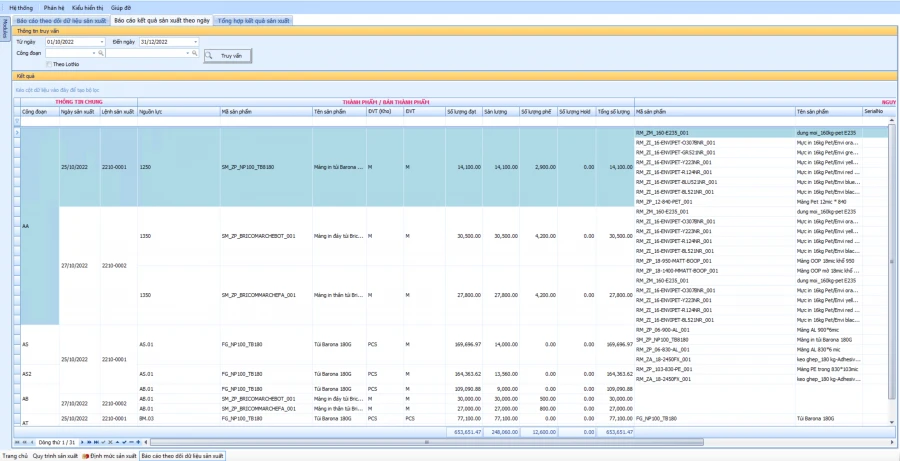

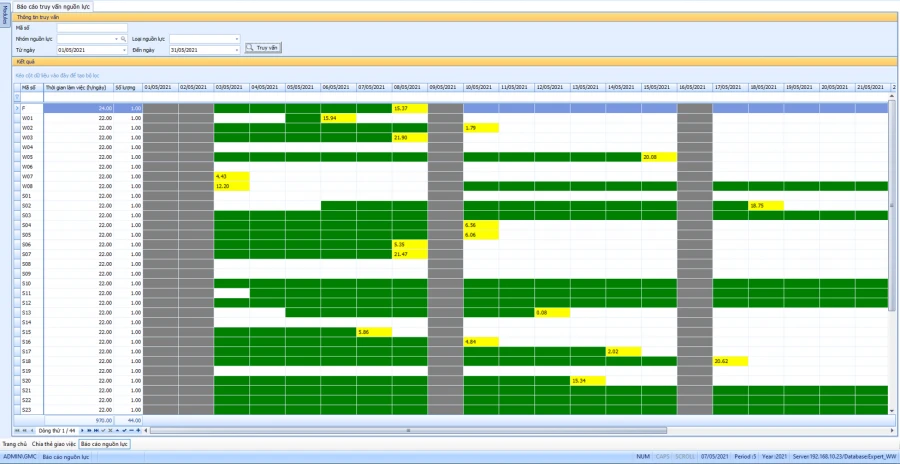

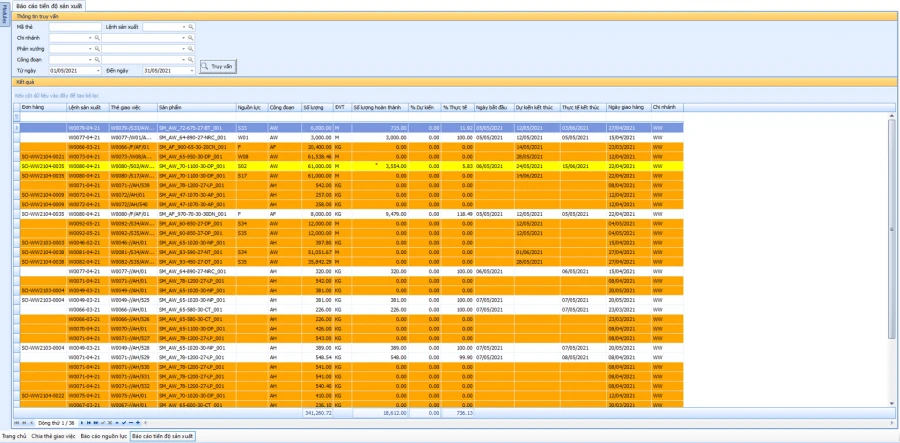

For Production Management:

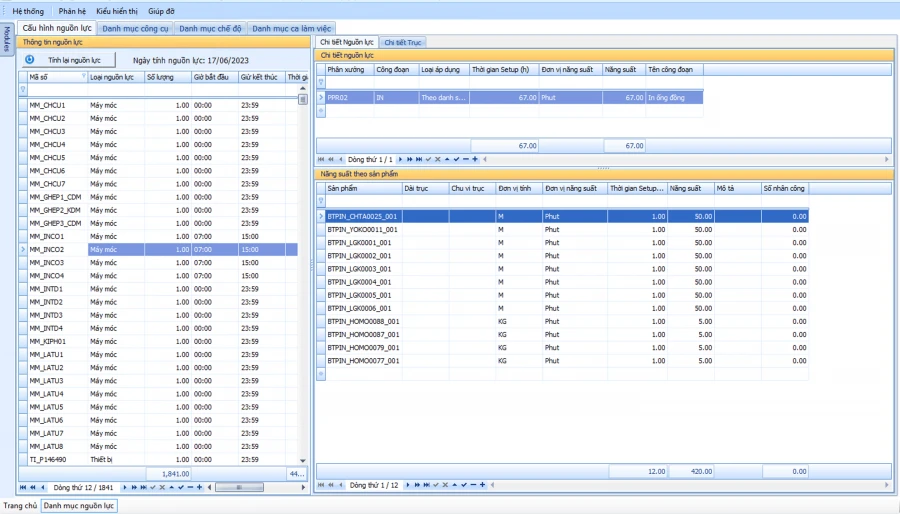

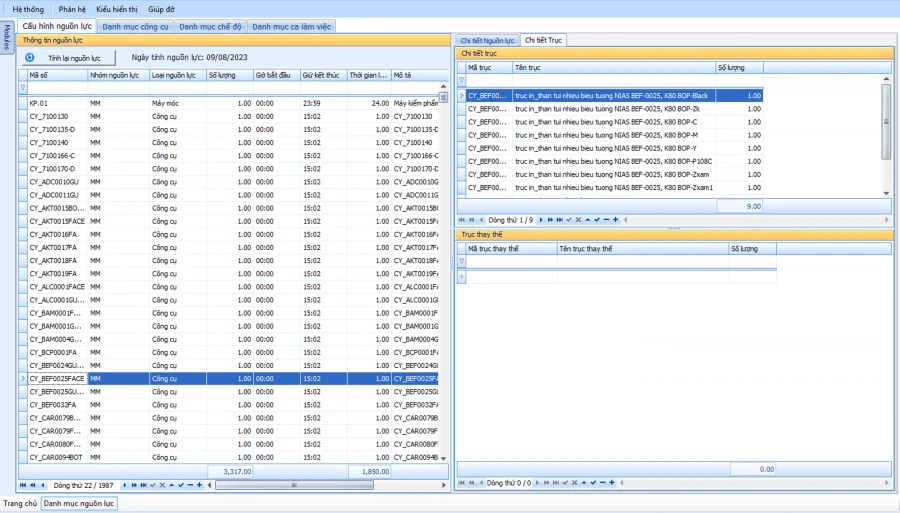

For Machine and Equipment Management:

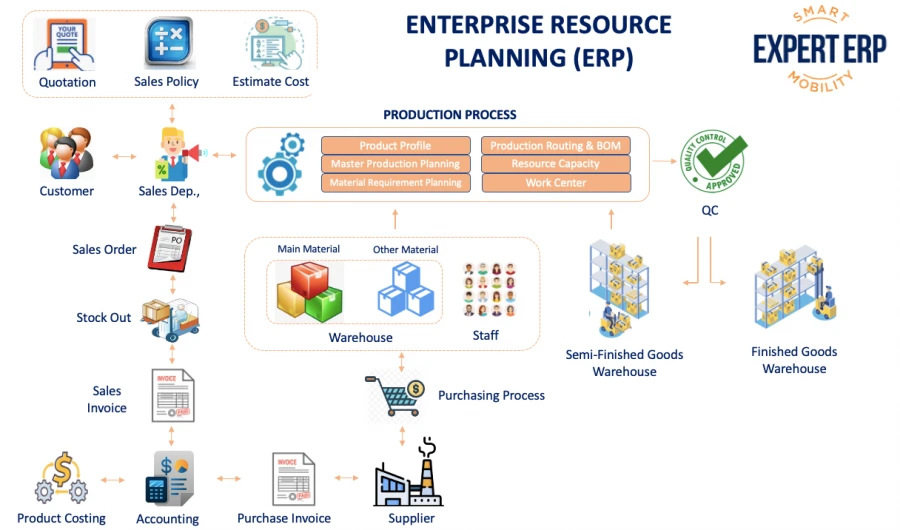

EXPERT ERP ENTERPRISE RESOURCE PLANNING SOLUTION MODEL

The software allows management:

Automatic calculation support system:

Automatic calculation system:

Ability:

Ability:

The software allows:

Ability:

Ability:

Ability:

Ability:

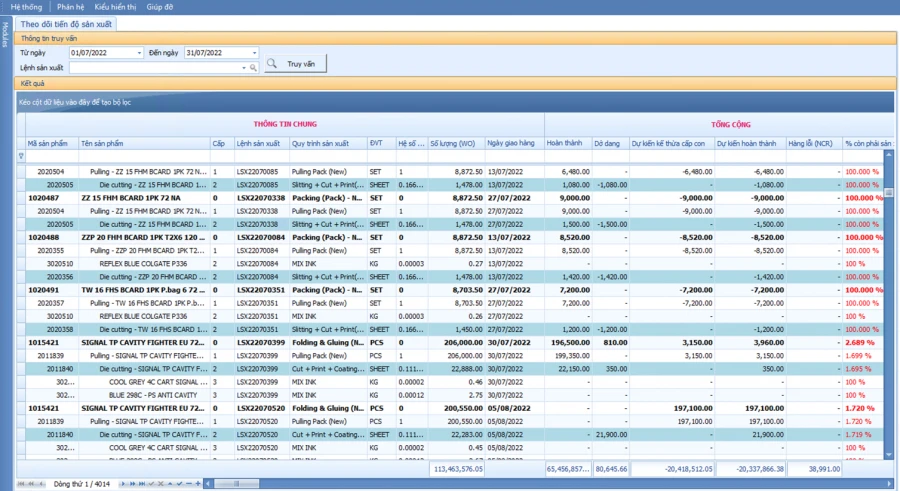

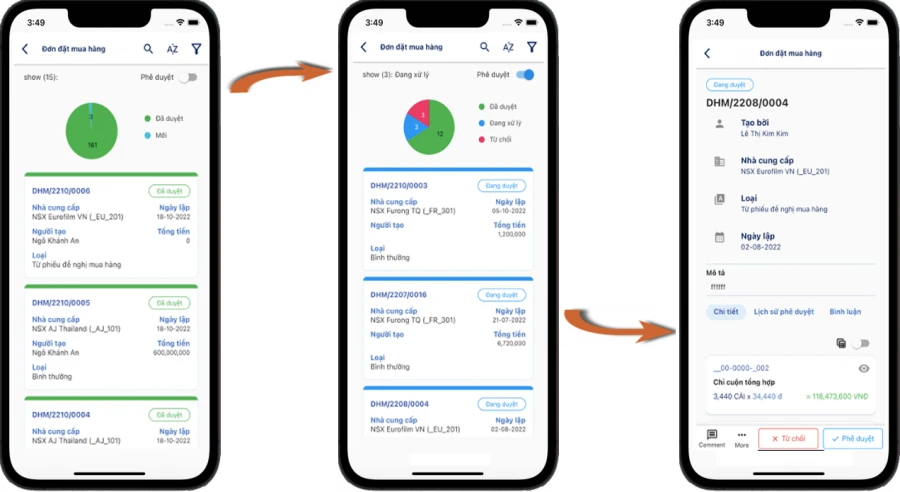

ORDER REVIEW

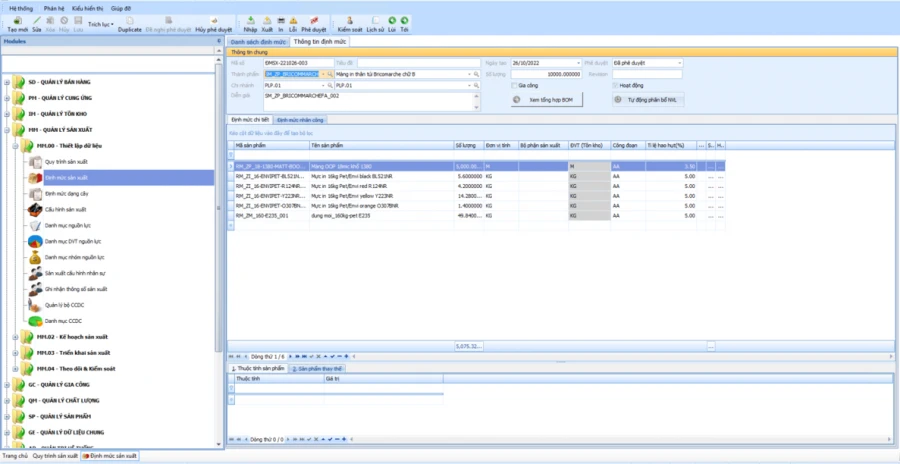

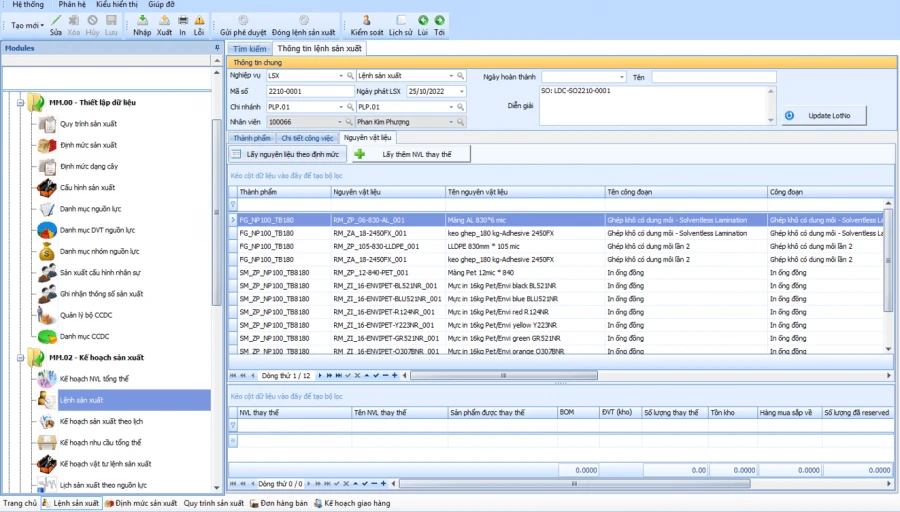

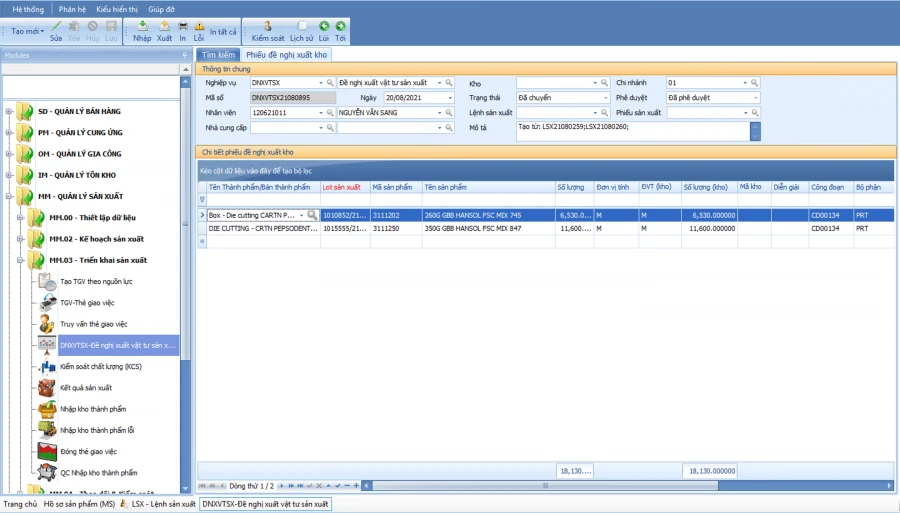

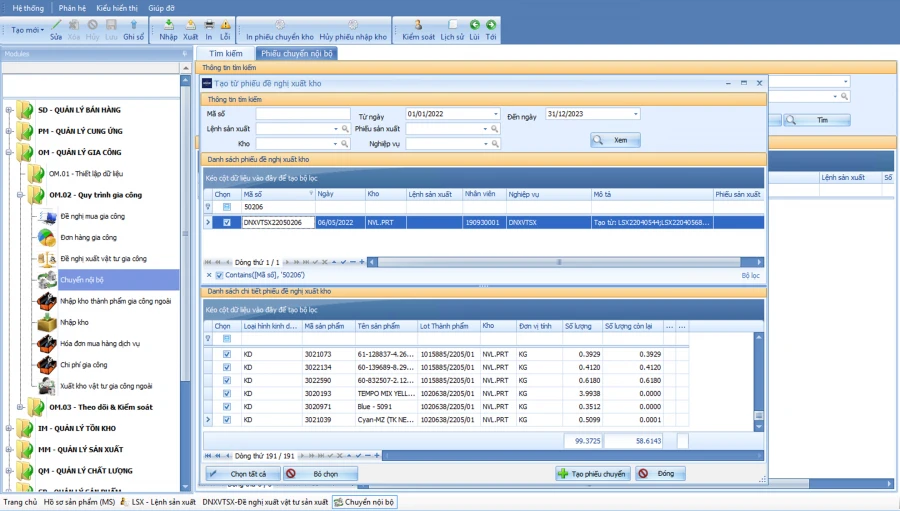

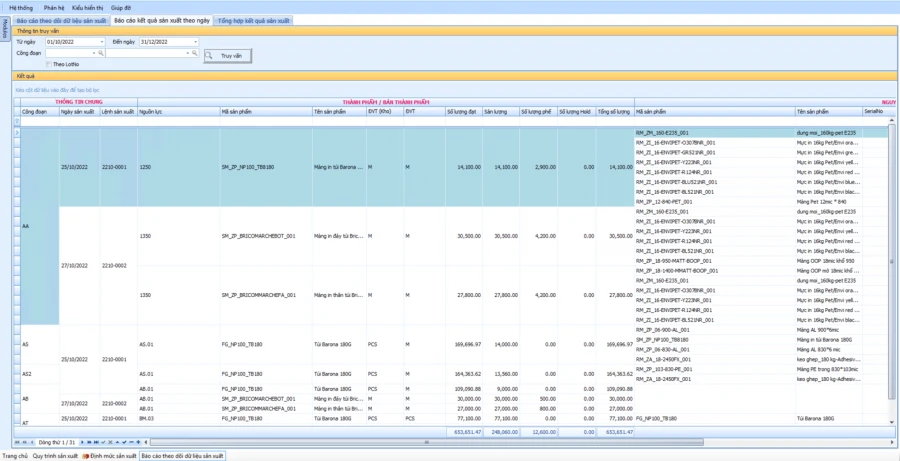

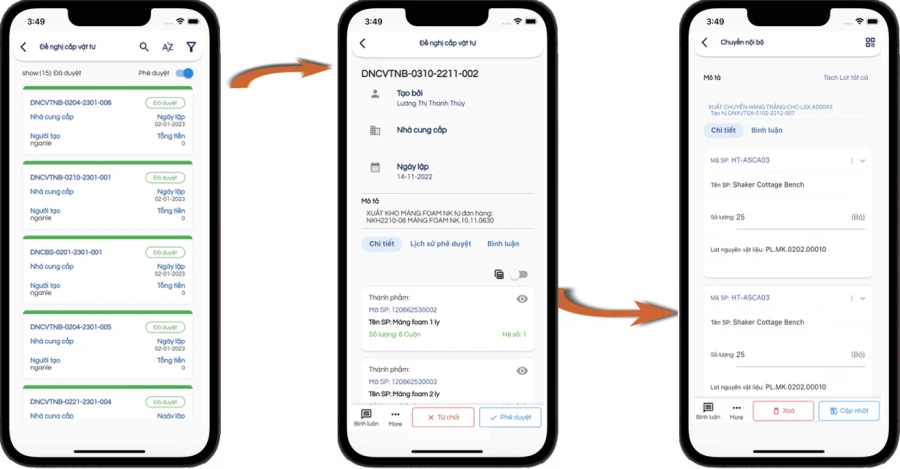

CONTROL THE LEVEL OF PRODUCTION MATERIALS

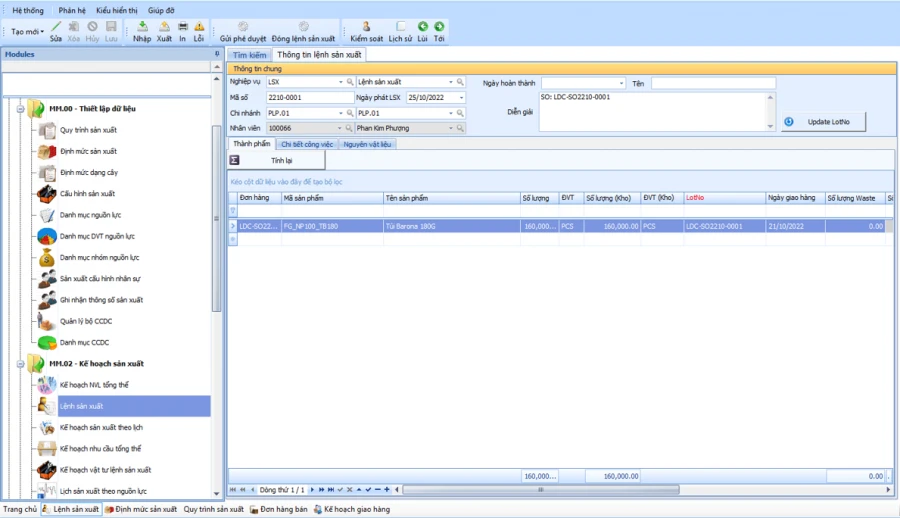

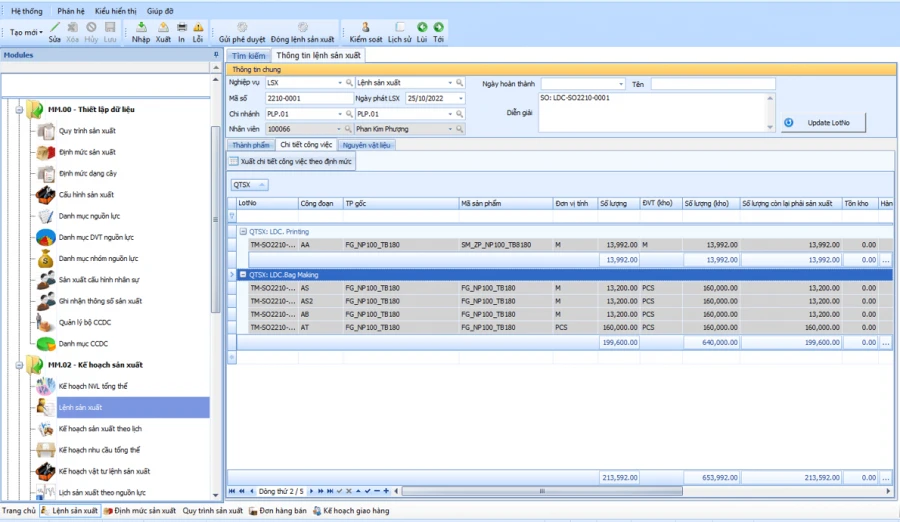

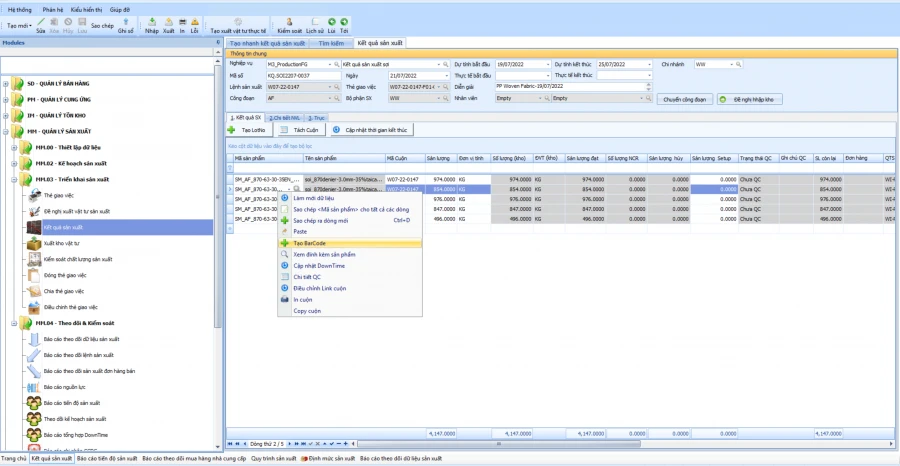

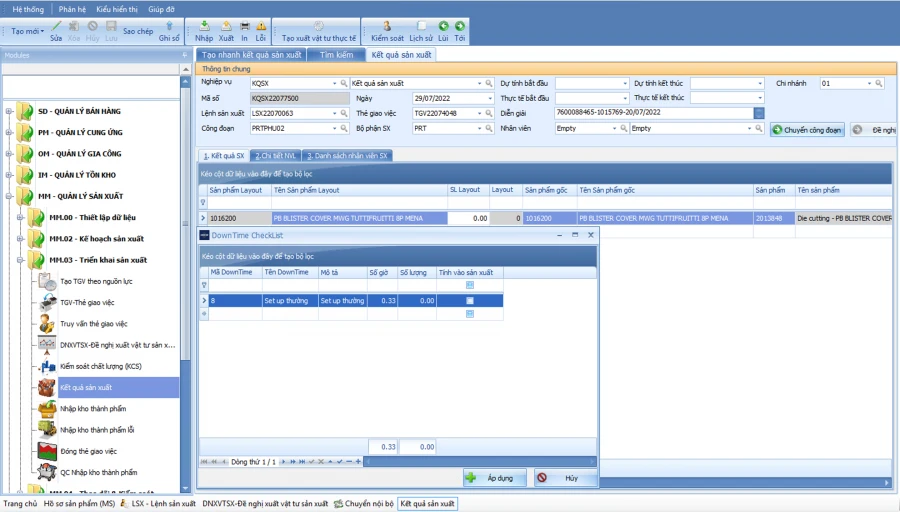

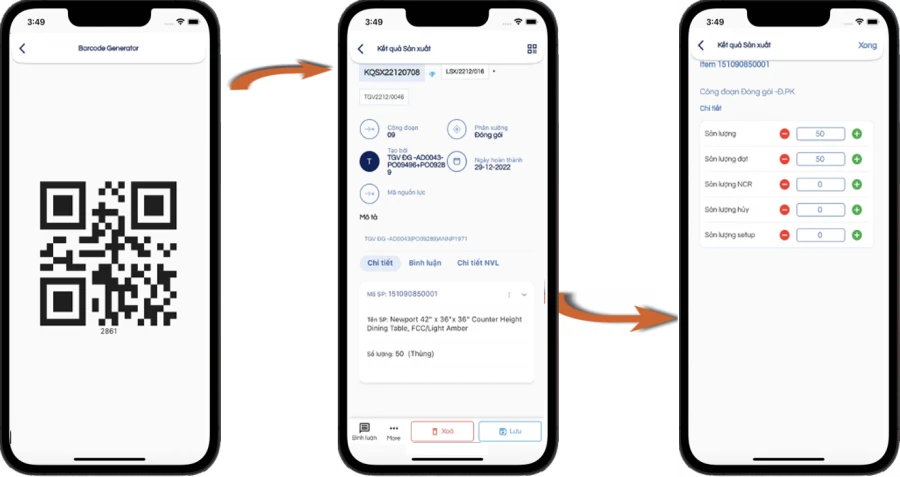

RECORD PRODUCTION RESULTS

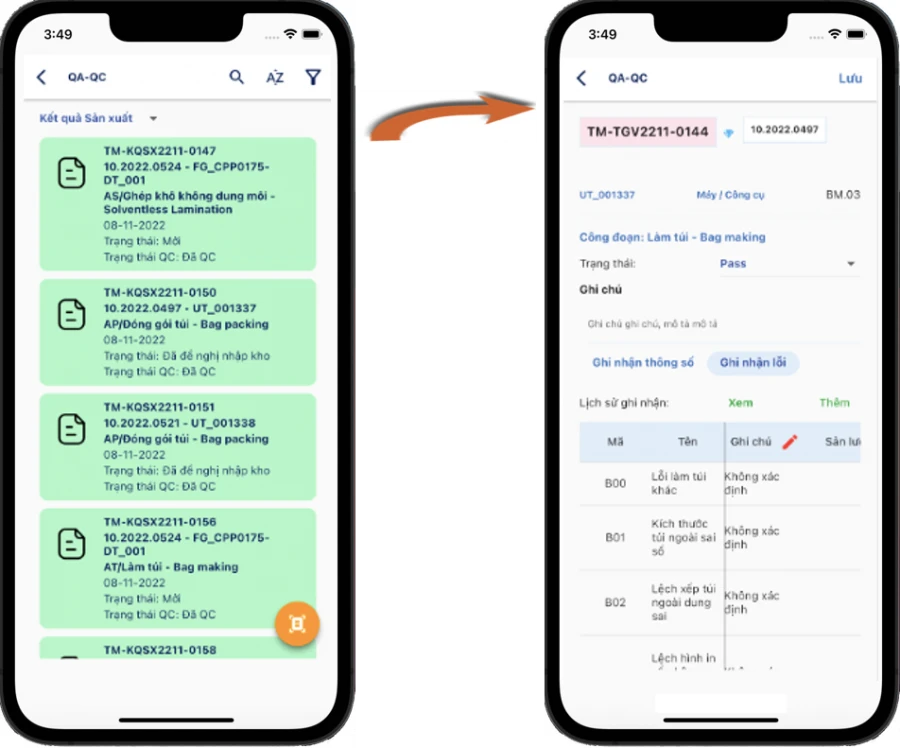

QUALITY ASSESSMENT BY LINE

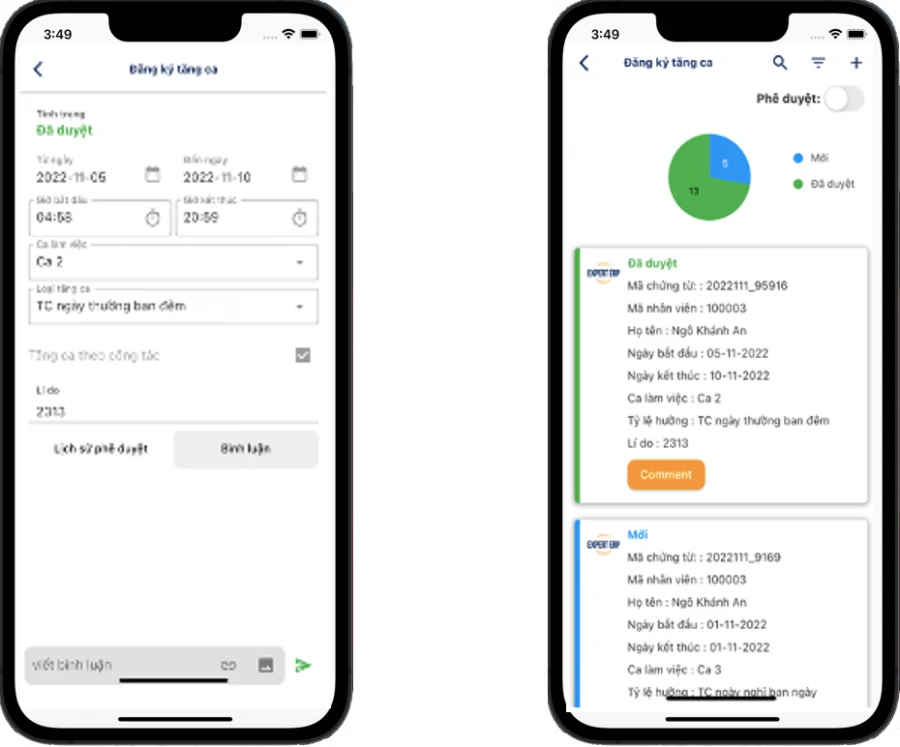

OVERTIME REGISTRATION

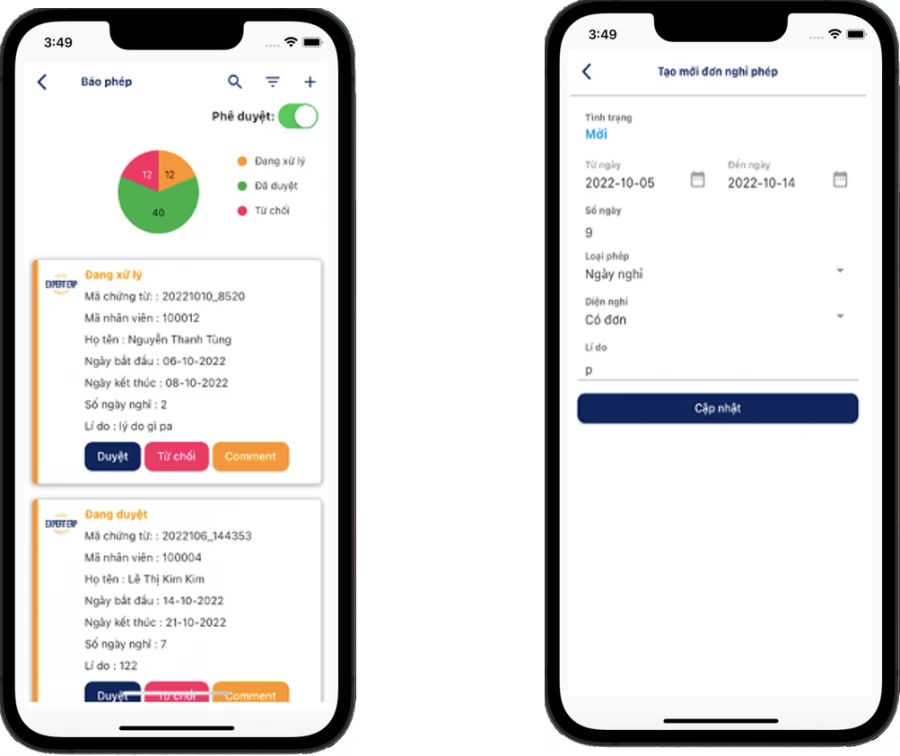

LEAVE REPORT

MACHINE STOP TIME ANALYSIS

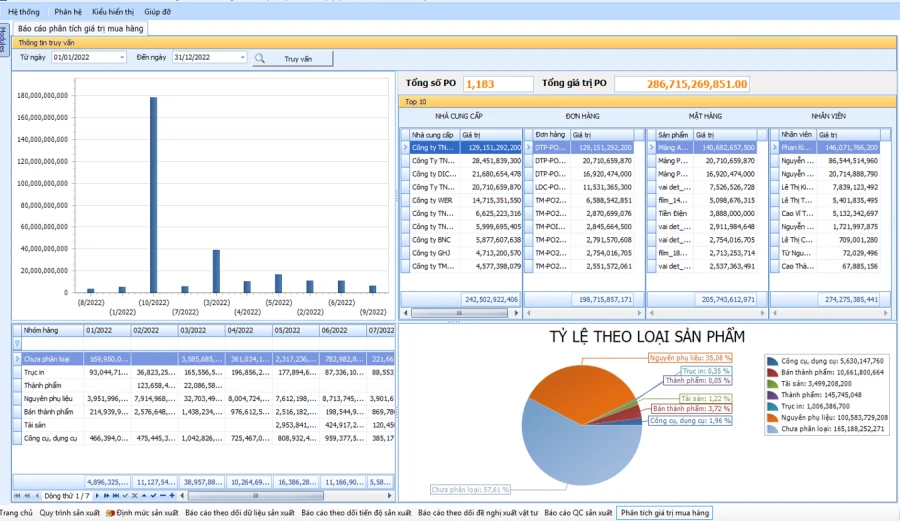

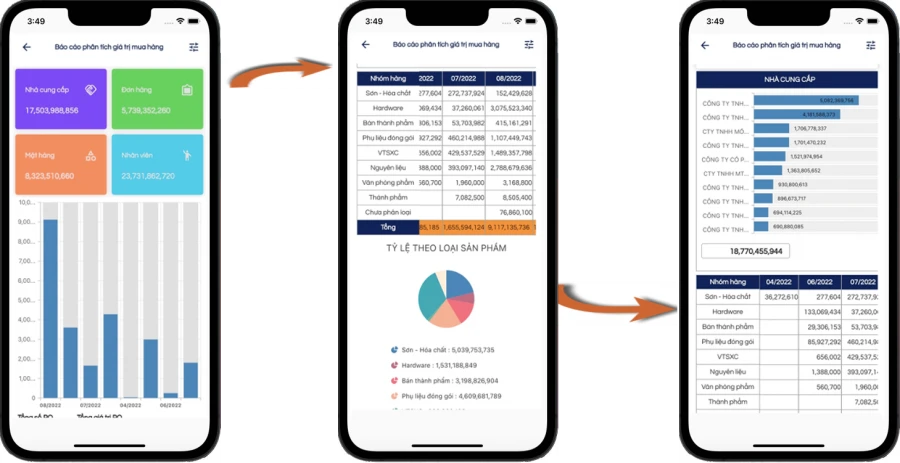

PURCHASE ANALYSIS

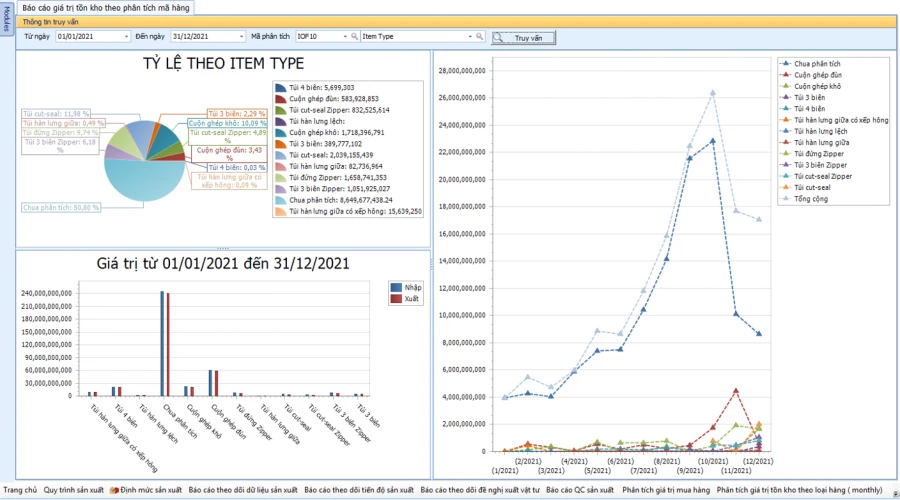

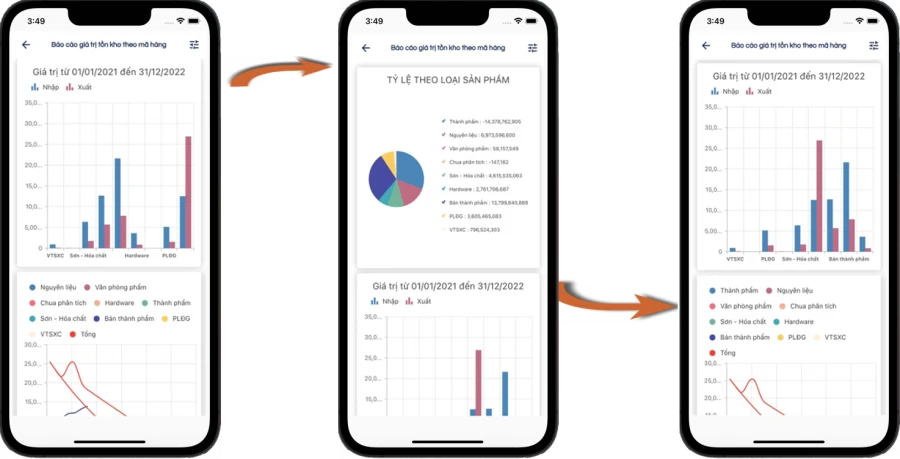

INVENTORY VALUE ANALYSIS

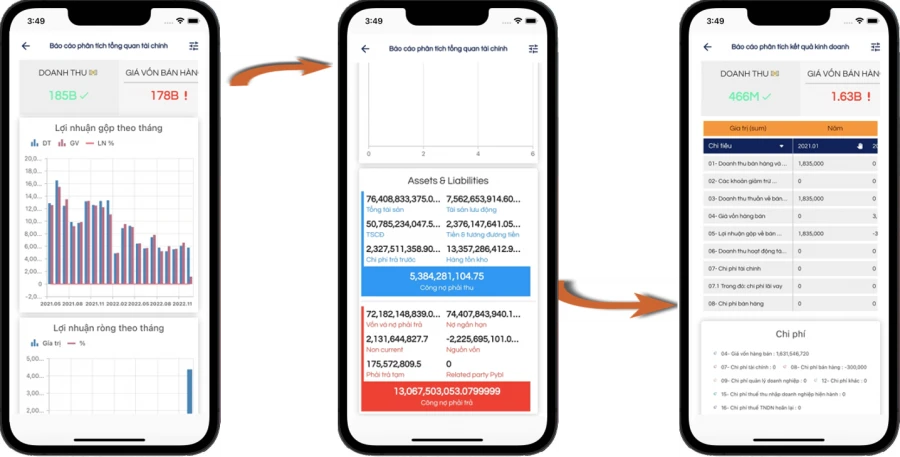

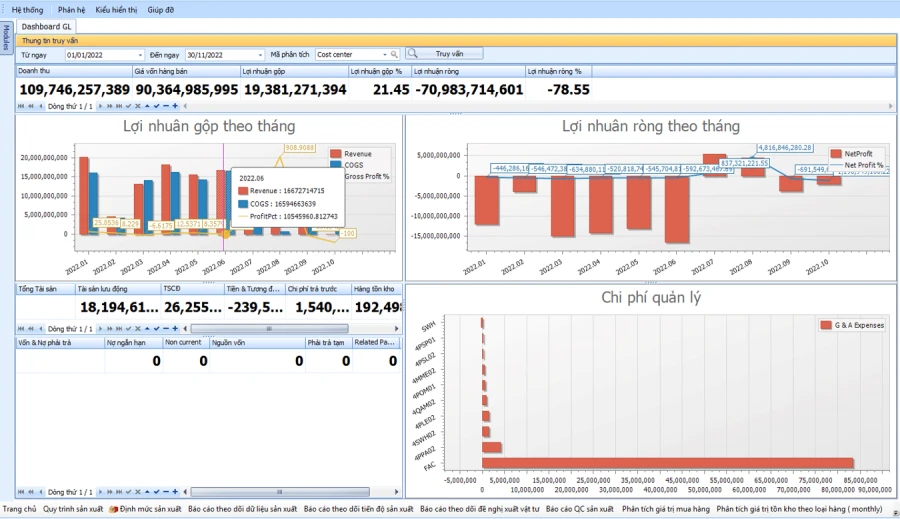

OVERVIEW OF FANANCIAL SITUATION