Production process

Divide and create a production stage/production center to manage the flow of raw materials, waste products and costs throughout the production process.

Lock/lock a production stage/production center.

Retrieve and report the status of stages/production centers.

Raw material norms

Import and manage the data level.

Calculate the formula content and product unit price of the raw material level determination based on the change in the quality of input materials and the purchase price of input materials.

Approve/lock in determining the level of materials for activities to plan material needs and/or production.

Production planning

Set up a safe warehouse level/minimum warehouse/maximum warehouse for each warehouse item.

Connect to the Subsystem of Warehouse Demand Planning of the Subsystem of Warehouse - Warehouse Management to get information on the demand planning of goods for sale.

Calculate the Production Demand Calendar based on the sales demand plan, safe warehouse level and initial inventory of the warehouse goods.

Divide the Production Demand Calendar into the Production Plan Calendar. Integrate the strategy to divide the Production Demand Calendar into an appropriate Production Plan Calendar to ensure the maximum efficiency of production activities while still ensuring the production cycle.

Planning the demand for materials

Advance planning

- From the Production Planning Calendar, calculate and determine the Raw Material Use History based on the required raw material level and the production time process.

- Calculate the Raw Material Requirement Calendar based on the Raw Material Use History, the safe storage level and the initial inventory of the material.

- Divide the Raw Ingredient Request Calendar into a Purchase Request Calendar with the purchasing/supply section. Integrate the strategy to distribute the Original Required Calendar

- Make a reasonable Purchase Request Calendar to ensure the effectiveness of purchasing activities and ensure the time of supply from the supplier.

Backward planning

- When the Purchase Request Schedule is implemented by the purchasing/supplying section into Order/Receipt Orders, the system will automatically calculate the Raw Request Schedule.

- Based on the comparison between the Material Requirement Calendar and the Material Requirement Calendar, the system will automatically detect the time of lack of material to alert the responsible staff to the manage.

- Based on the Material Inventory Calendar, the system will automatically calculate and distribute the available/purchased materials into the corresponding Production Schedules in the Production Planning Calendar.

Execute production orders

The production schedule for Production Supps has been planned to be put into production based on the predetermined criteria:

The urgency of the output of the Production Order.

Production Scale.

Raw materials for the Production Leder.

Machinery and equipment for Production.

Laborers serving for the Production Service.

Approve the Production Order for put into actual production. Division of Production Lots into Production Lots

Enter and manage records of Production Lots.

Create Material Transfer Notes with the warehouse (via Warehouse Division - Warehouse Management). Monitor the delivery of raw materials from warehouse to production.

Monitor the status/cost/output of each Production Batch at each stage of production/each production process.

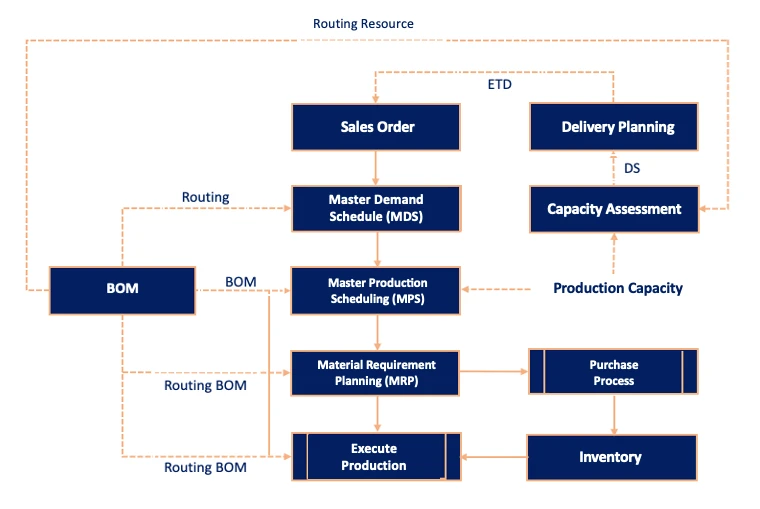

OVERVIEW PROCESS

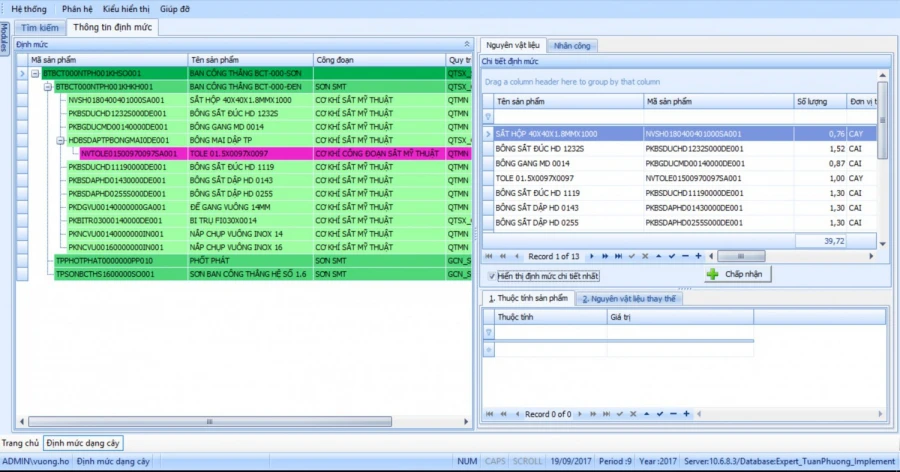

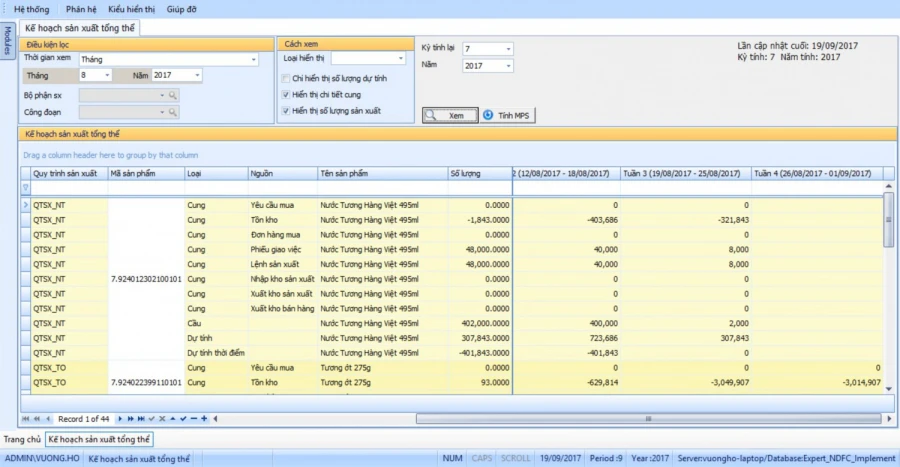

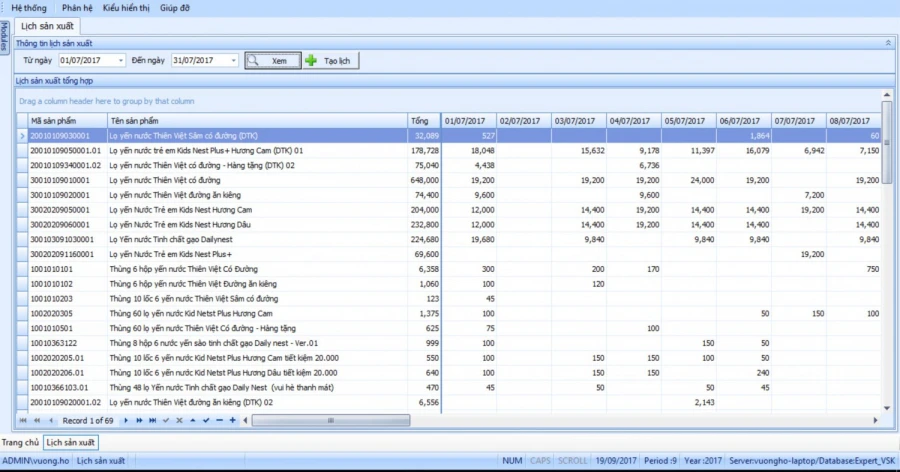

SOME PRODUCTION MANAGEMENT INTERFACE SCREENS

Figure 1: Production norm (My-level)

Figure 2: Overall Production Plan (MPS)

Figure 3: Production Calendar (Production Calendar)

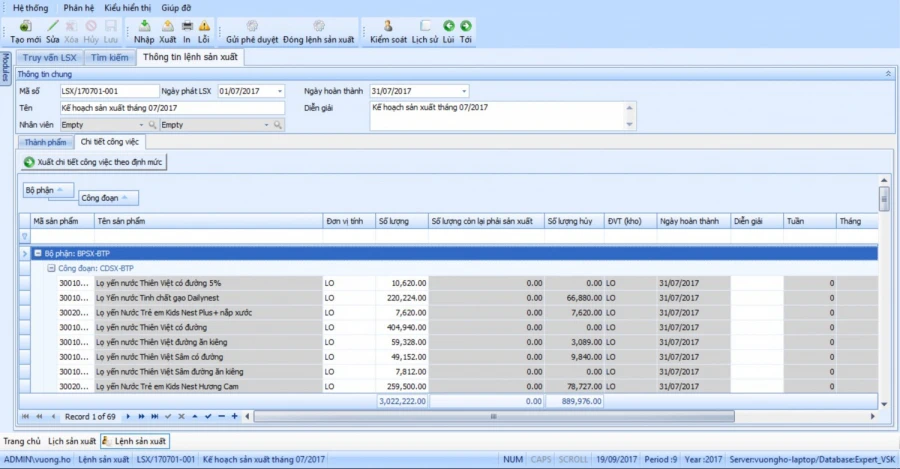

Figure 4: Production Order (Work Order)

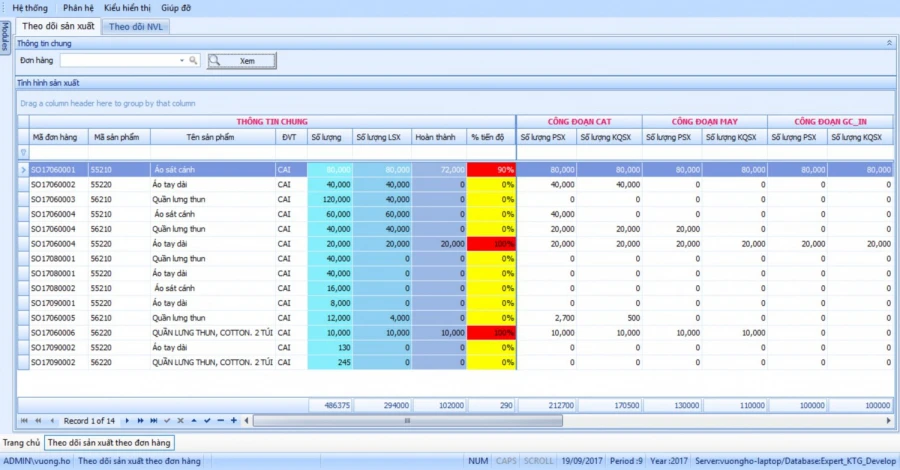

Figure 5: Production progress monitoring report