Pharmaceutical (drug) production in Vietnam is classified into two types based on the origin of the drug:

New medicine

New medicine was introduced to our country along with modern medicine (western medicine), so it is often called western medicine. Those are drugs produced from chemicals, some types of microorganisms, compounds from plants prepared in pure form or some natural compounds that are semi-synthesized into other substances. A small number of new drugs are prepared from animal products.

New drugs have a strong and convenient treatment effect, however, the main origin of new drugs is from chemicals, so they can cause some adverse side effects for patients.

Oriental medicine

Oriental medicine associated with traditional Chinese medicine, are drugs derived from plants (Medicinals) such as plants, stems, leaves, fruits, minerals, animals. Currently, some medicines are still prepared according to traditional methods, others are prepared in modern forms such as tablets, capsules, tea... to increase the convenience for users.

Oriental medicine has a slower treatment effect than new medicine, but oriental medicine can solve some chronic diseases according to the body's balanced conditioning mechanism. This is the unique strength of oriental medicine that modern medicine cannot deny.

In 2020, the Covid-19 pandemic affected many economic sectors of Vietnam, including the pharmaceutical industry. However, the survey results of Vietnam Report just conducted at the end of 2020 show that, compared to other industries, pharmaceuticals are one of the least affected industries because this is one of the essential products for people. Specifically, 64.3% of pharmaceutical enterprises responding to the survey said that they were moderately affected; 28.6% of enterprises assessed the impact was small and insignificant and only 7.1% of enterprises assessed that they were seriously affected.

The outbreak of the pandemic caused the demand for pharmaceuticals to spike, especially with drugs that strengthen resistance. Hospitals and individual customers all need to stock up on drugs to prevent epidemics. For enterprises in the medical supplies industry, the production and supply of medical equipment and protective equipment during the Covid-19 epidemic has contributed to a significant increase in revenue for these enterprises, even enterprises with net revenue and profit increased by three digits compared to the same period in 2019.

However, not all pharmaceutical and medical supplies businesses benefit, but the business situation of pharmaceutical enterprises is relatively diversified during the Covid-19 pandemic. In addition to large-profit enterprises with strong growth, the pharmaceutical industry also recorded many enterprises with a decrease in profits, including enterprises that recorded losses due to the impact of the epidemic. Although the situation has improved after Vietnam controlled the epidemic, according to the assessment of many businesses, the recovery level has not reached the same as before the pandemic. This is evidenced by the business results of domestic pharmaceutical companies that have hardly grown in 9 months. According to Vietstock's summary, in the third quarter of 2020, 18 pharmaceutical enterprises listed on the stock exchange generated nearly VND 8,796 billion in net revenue and VND 530 billion in net profit, respectively, decreasing by 4.9% and increasing by 7.6% over the same period.

The survey results also show the leading difficulties of pharmaceutical enterprises during the Covid-19 pandemic. Specifically, 78.6% of enterprises face difficulties when the demand of users of pharmaceutical products changes; 57.1% of enterprises have difficulty when approaching new customers, breaking the supply chain in business, increasing the price of input goods and 35.7% of enterprises have difficulties with competition between enterprises in the industry.

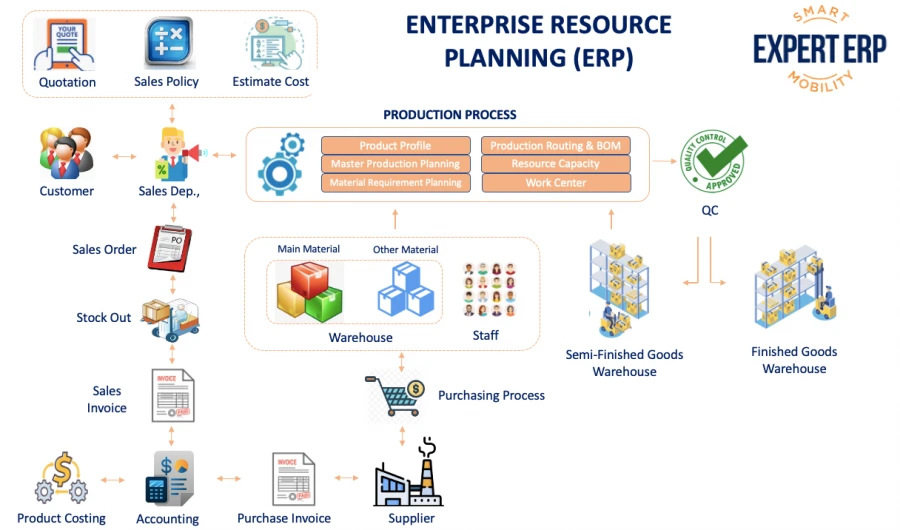

With in-depth knowledge and experience in research, analysis and development of Enterprise Resource Planning (ERP) Solutions in Europe. We build ExpertERP Solutions according to advanced technology, international standards with a process that both meets the multidisciplinary direction and can solve specific problems and intensive management requirements by industry.

With a team of experienced experts, successfully deployed for pharmaceutical manufacturing businesses in Vietnam. ExpertERP Total Management Solution applies to all business - production activities of enterprises, thanks to the application on a single platform of systems, software and databases, the flow of information data ensures transparency, seamless, instant, accurate. Allow access to data and statistics, instant reports, "Anytime - Anywhere - On any device", support the Leadership to make timely and correct decisions.

The Covid 19 pandemic situation will continue to have a bad impact and cause many difficulties for the production - business activities of enterprises in general, the pharmaceutical manufacturing industry in particular. However, this is a favorable time for businesses to stabilize, re-regulate all activities, and move towards a comprehensive "DIGITAL TRANSFORMATION" of the company. If you want to be highly capable of improving management, increasing labor productivity, and increasing profit margins, you must digitize all core activities of the enterprise, which is the Application of ENTERPRISE RESOURCE PLANNING (ERP) SOLUTION. With successful deployment experience for many businesses in the industry, GMC's ExpertERP Solution will help your business achieve these key goals.

EXPERT ERP ENTERPRISE RESOURCE PLANNING SOLUTION MODEL

Manage all care activities, exchange information, work, pursue customers of the marketing - sales team.

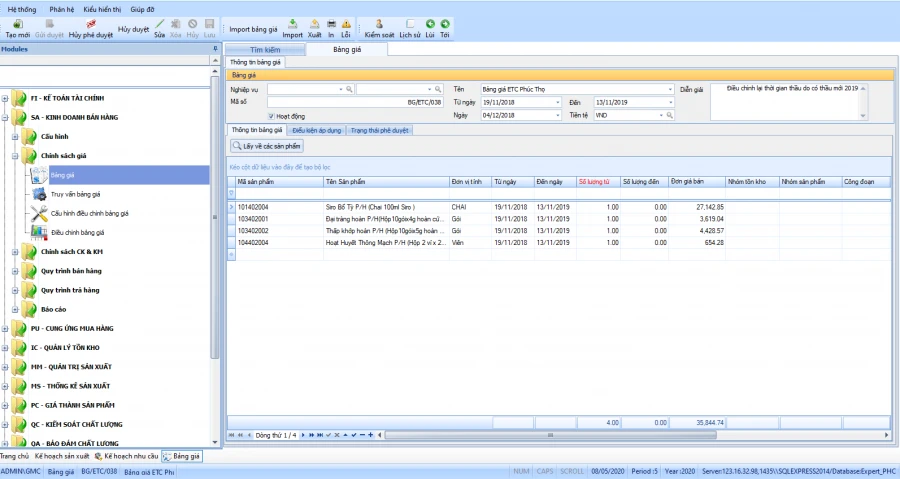

Support the sales department to calculate and build quotations according to the company's policy. Manage the entire transaction history of customers from quotes, orders, contracts, payments, ...

Help manage all supplier information, transaction history, price, payment policy, delivery, product warranty service quality, supplier evaluation.

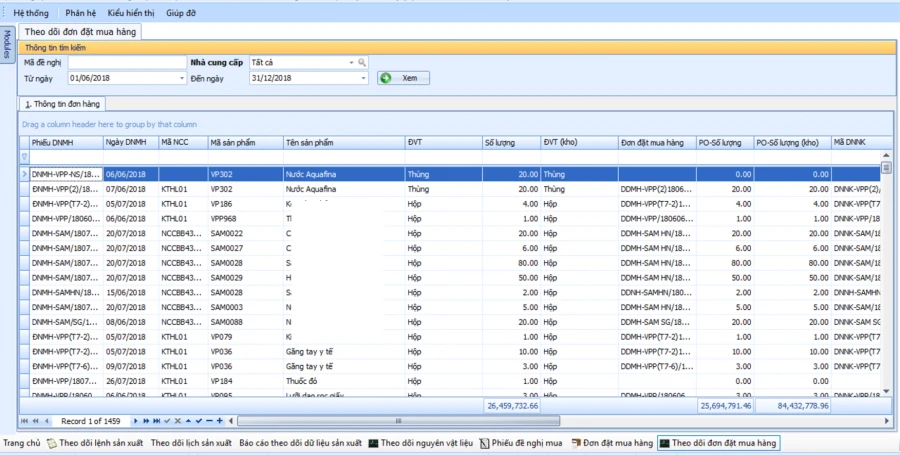

Support the Purchasing Department to make a purchase and supply plan based on the company's general business & production plan. Help track and manage orders from the time of purchase to the time of return to the warehouse, quality inspection, warehouse.

Support the Human Resources Department to manage all employee information, shift division, timekeeping, salary calculation, bonus, social insurance-health insurance-personal income tax, ... Establish, evaluate and monitor personal productivity targets (KPI) for each department, department.

Support in building Sales - Purchasing - Supplying - Production Plans.

Automatic planning of production plans based on the production capacity of each production resource in the factory by the ability to determine the productivity of machinery/manpower/tools according to each product in each stage.

From the production plan according to order/contract (Make to order) or production into the warehouse (Make to stock), it is possible to immediately refer to the data on available inventory; ordered goods; goods on the way to the warehouse; semi-finished products (in stock; on the line), ... calculate resources (NVL-Suppliance-Machinery-Workers-Time) to meet the production requirements of the order/contract or warehouse.

Especially production statistics by stage by mobile app, simple, easy to use, instant and accurate data, helping the Board of Directors have "real time" aggregate data to make timely and correct decisions.

All production - business data entered by departments and departments will be run to the Accounting-Finance Department to check, verify, calculate inventory, costs, profit and loss, balance cash flow and expenditure, loans, investment, ... immediately advise when the Board of Directors needs reporting data.

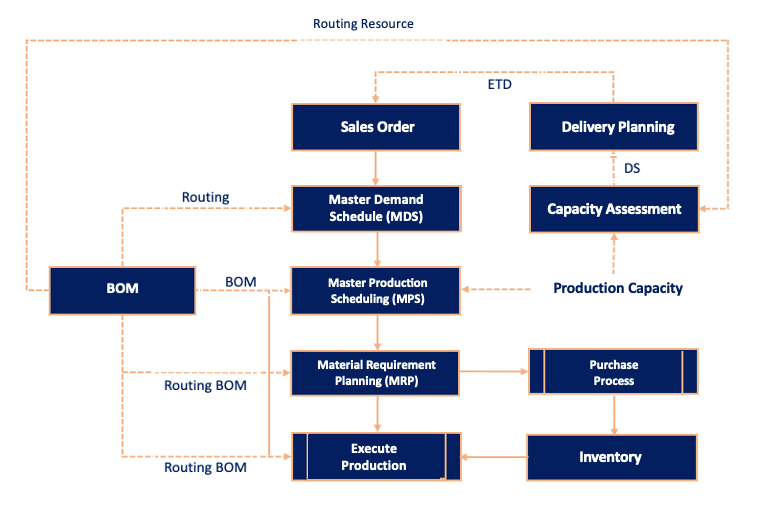

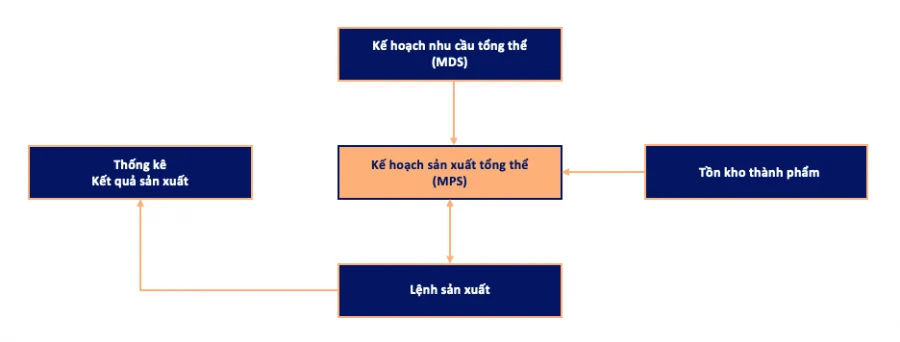

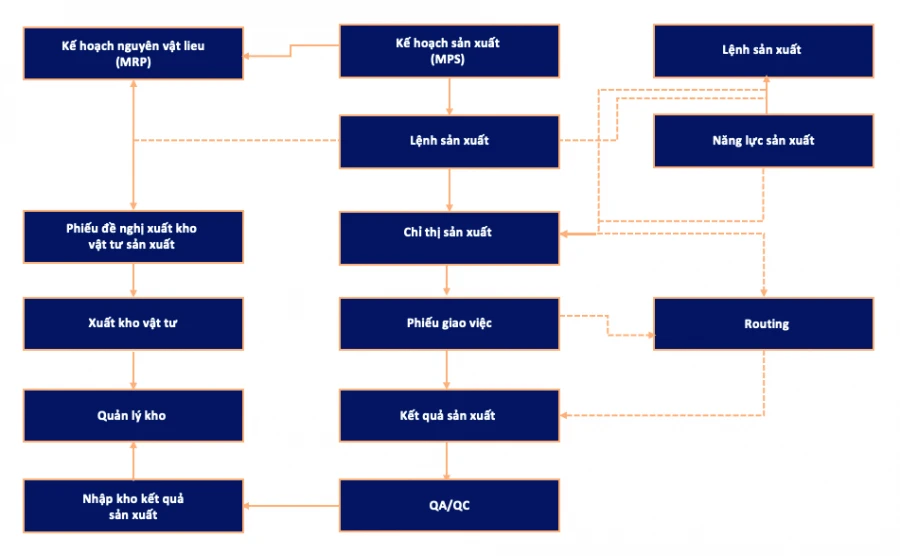

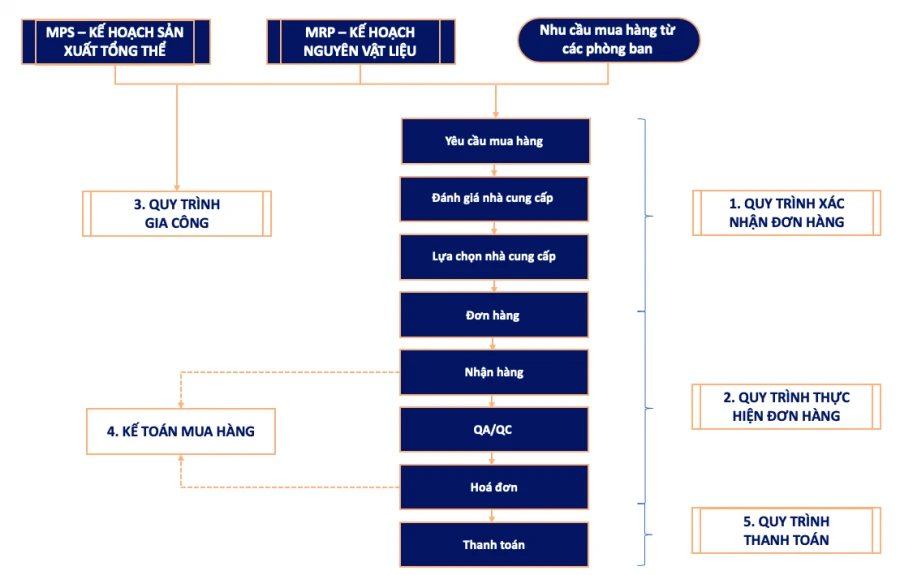

OVERALL PROCESS

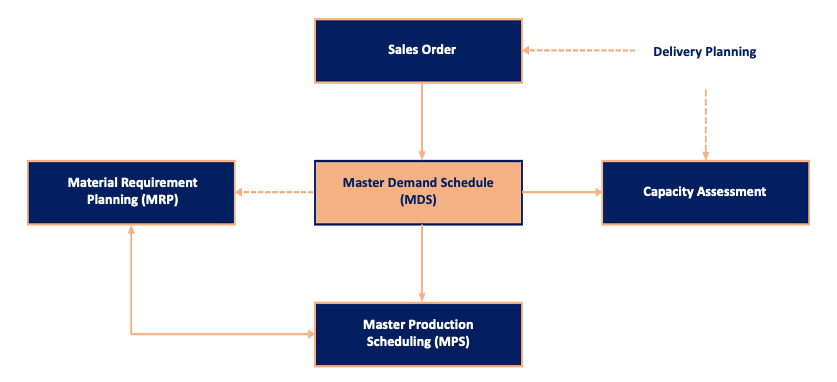

DEMAND PLAN

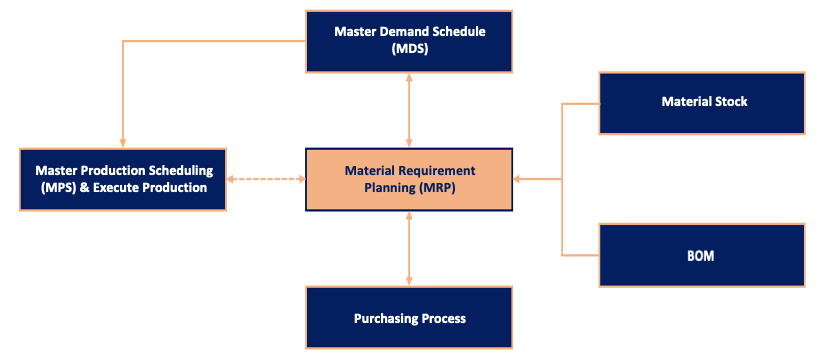

MATERIAL PLAN

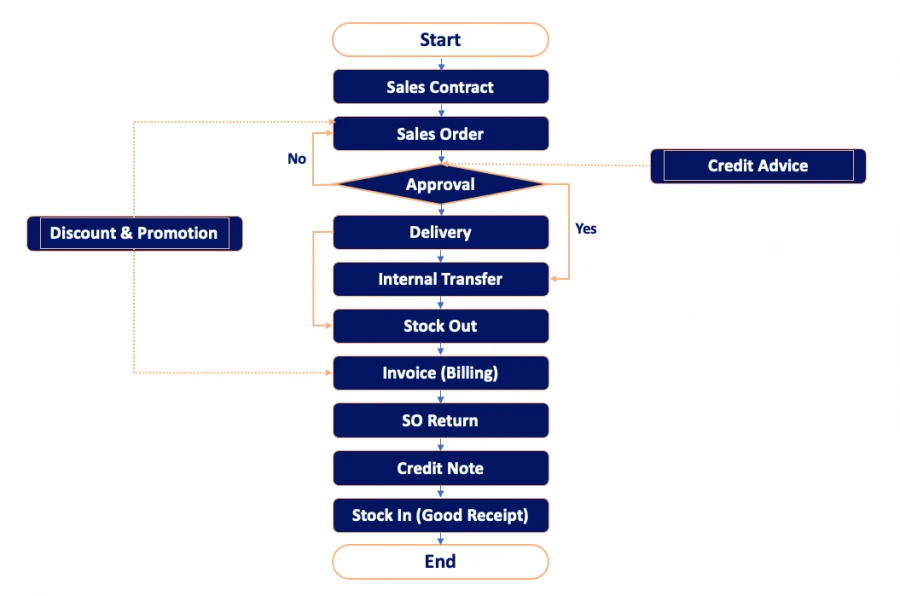

SALES PROCESS

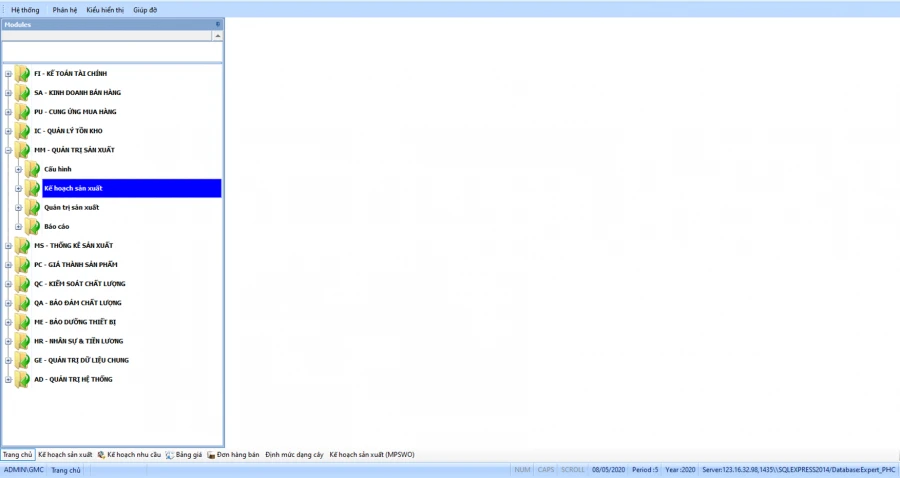

INTERFACE OF SUBSYSTEMS

Price list

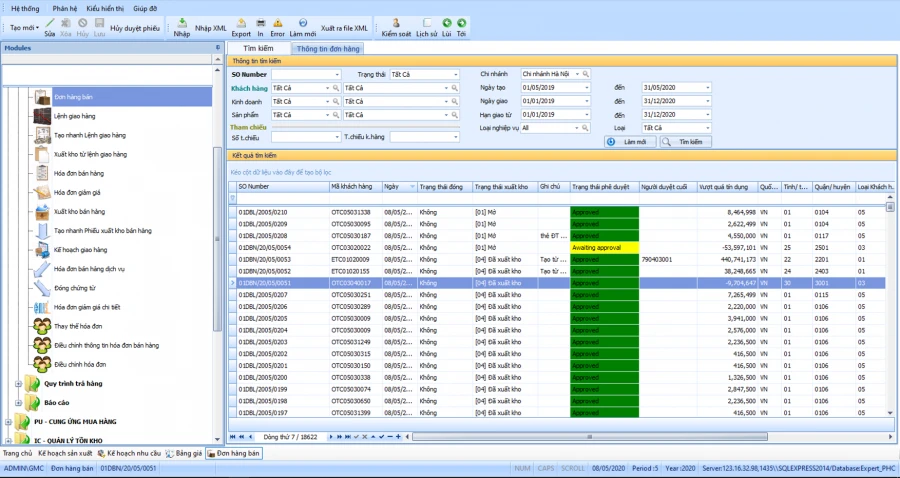

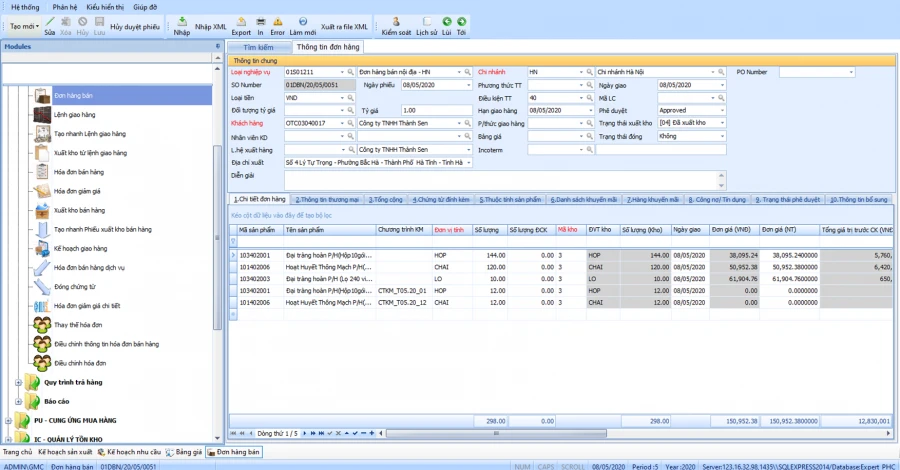

Order management

Order

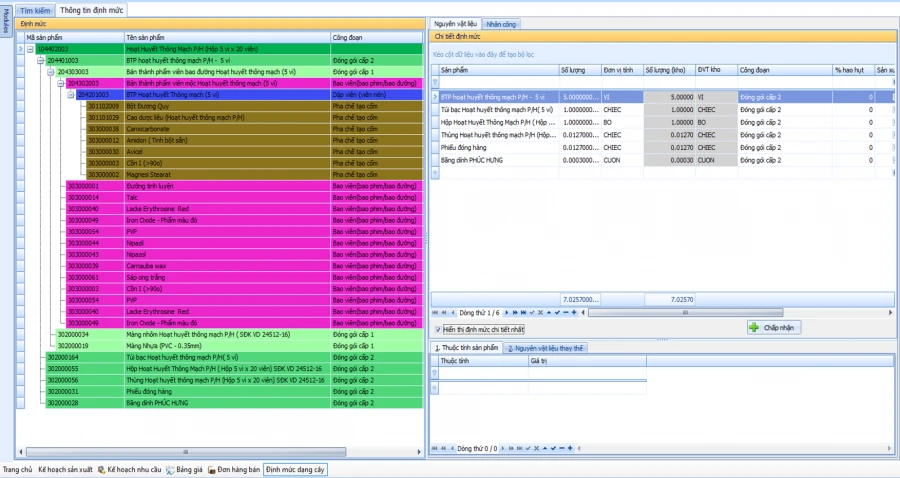

Production norm management

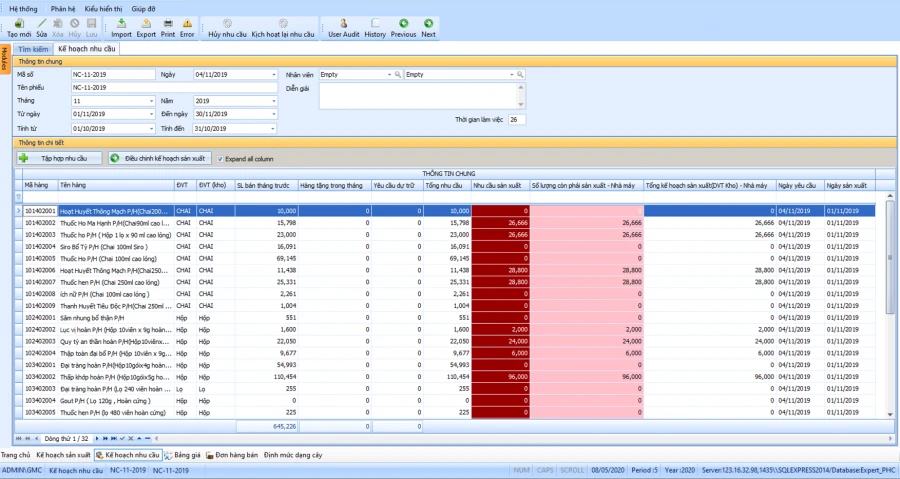

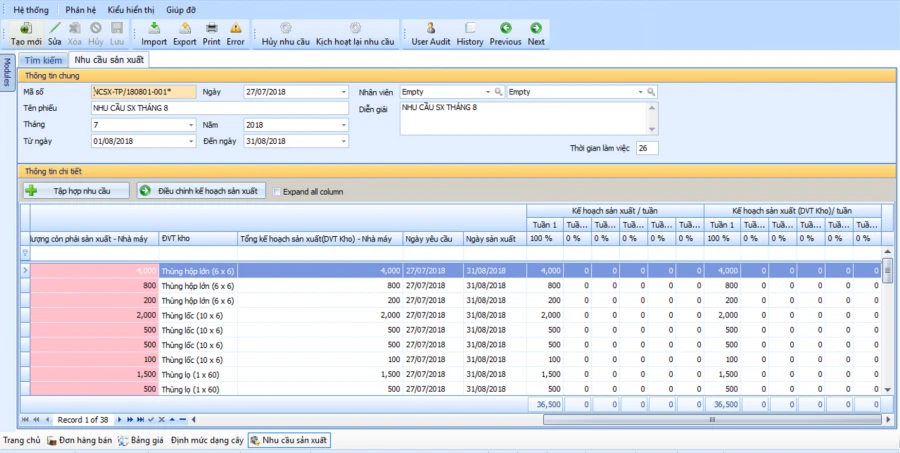

Production demand planning

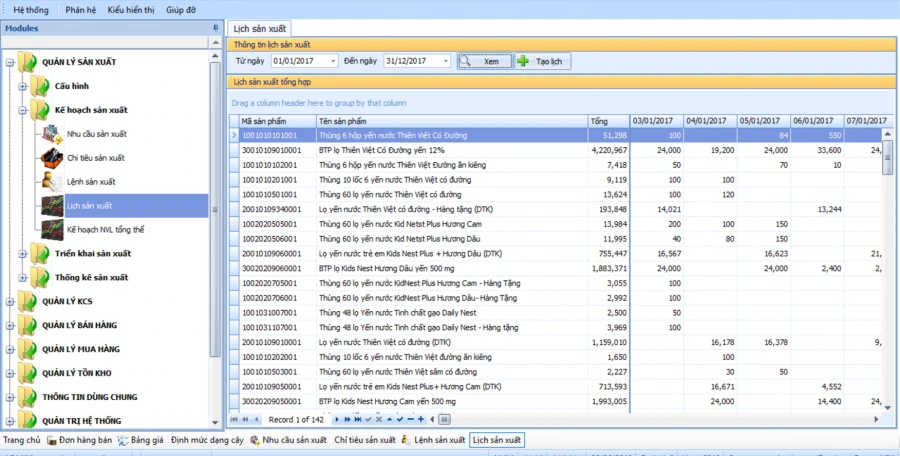

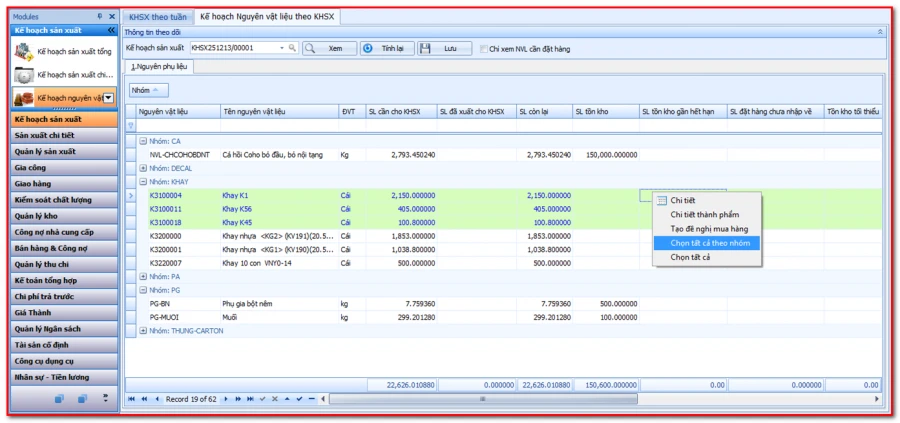

Weekly production demand planning

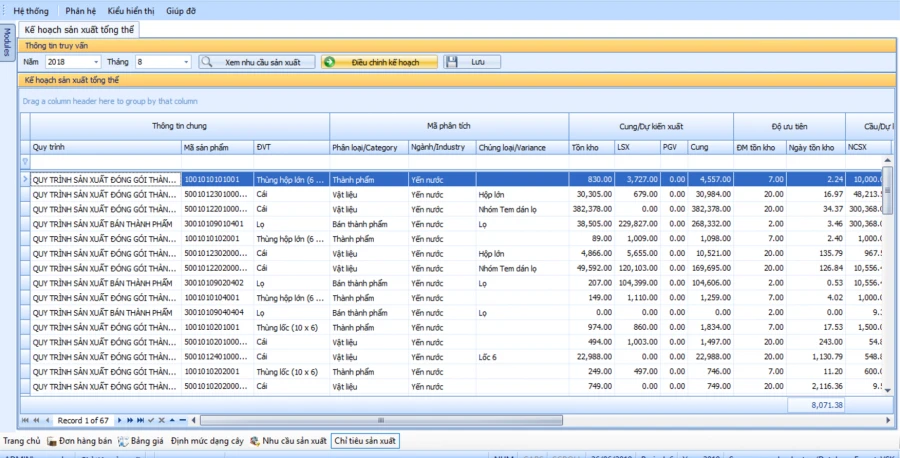

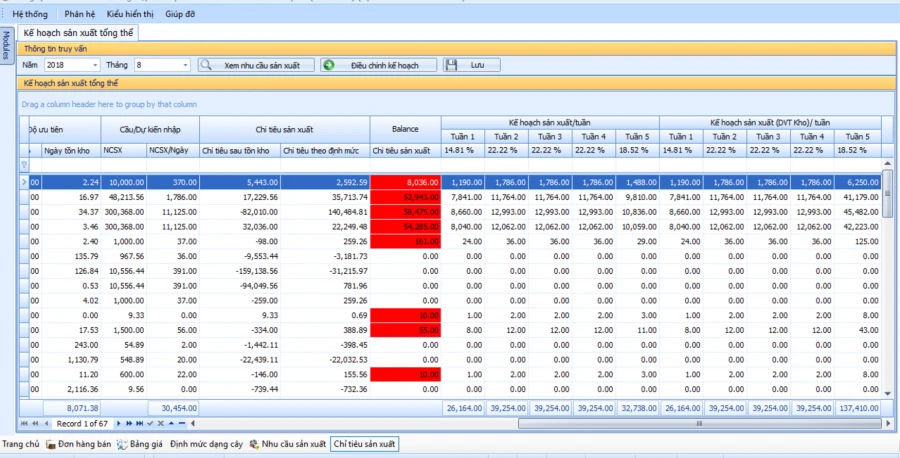

Overall production plan

Weekly production plan

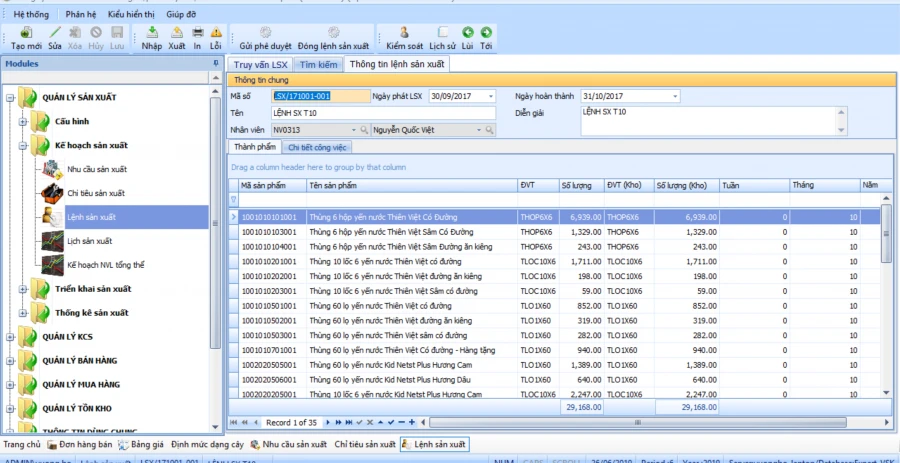

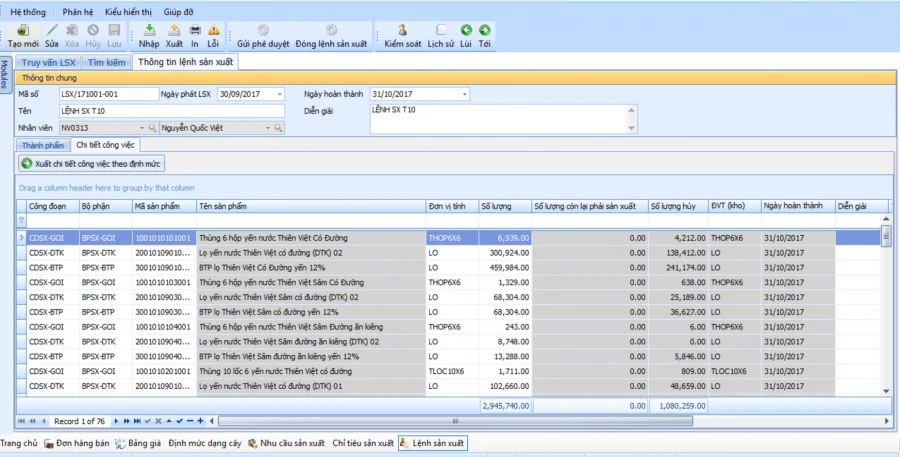

PRODUCTION ORDER ISSUANCE PROCESS

Production plan

Production implement

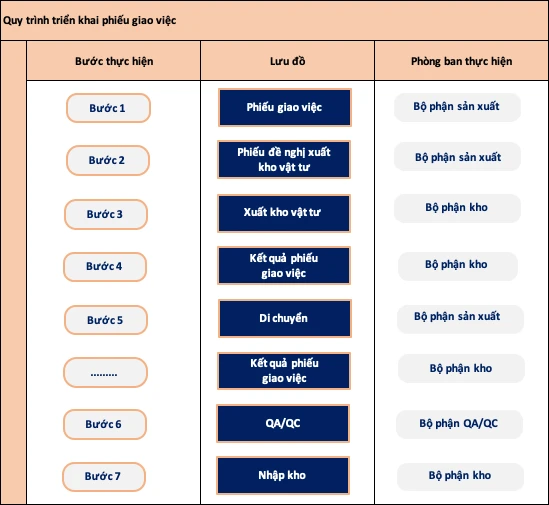

Implement the assigned form

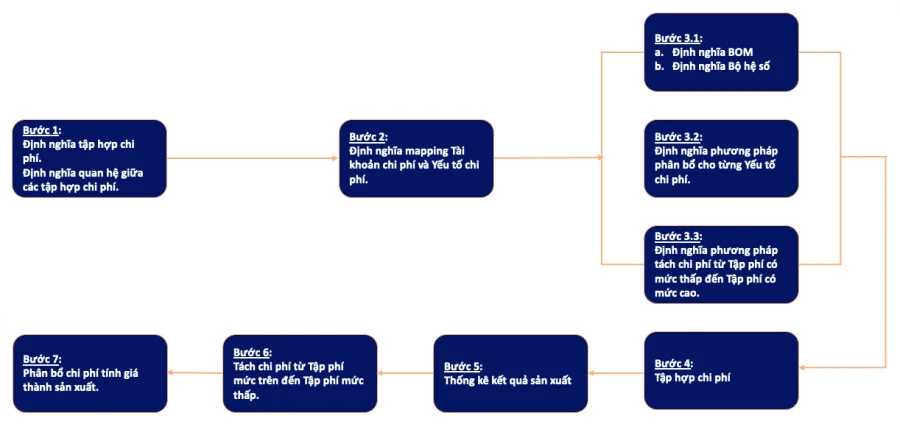

Cost calculation process

Production order

Divine the work from the production order

Production scheduling based on factory resources

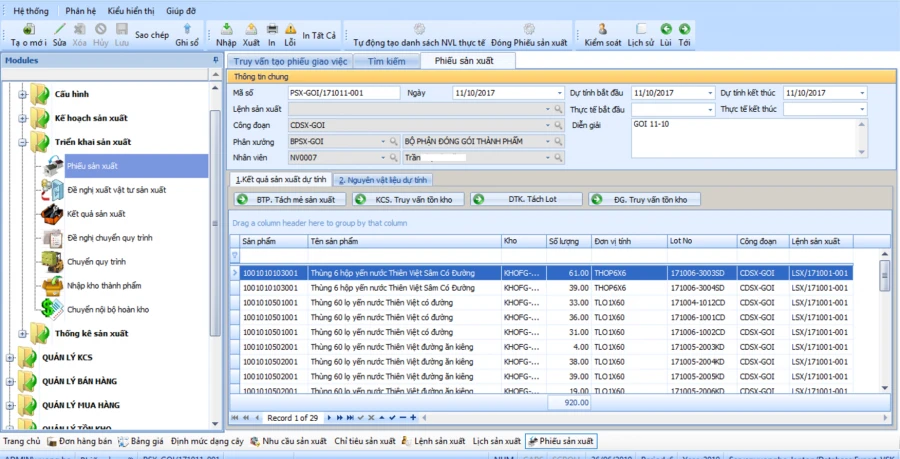

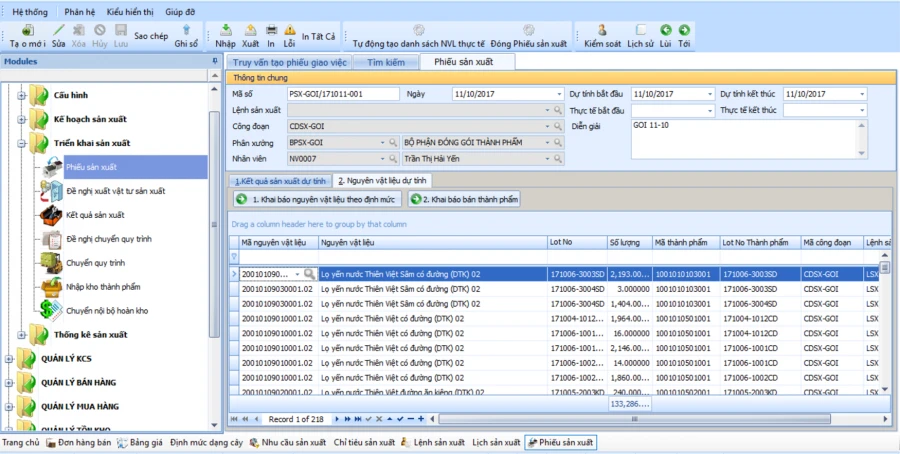

Production ticket

Expected raw materials for production ticket

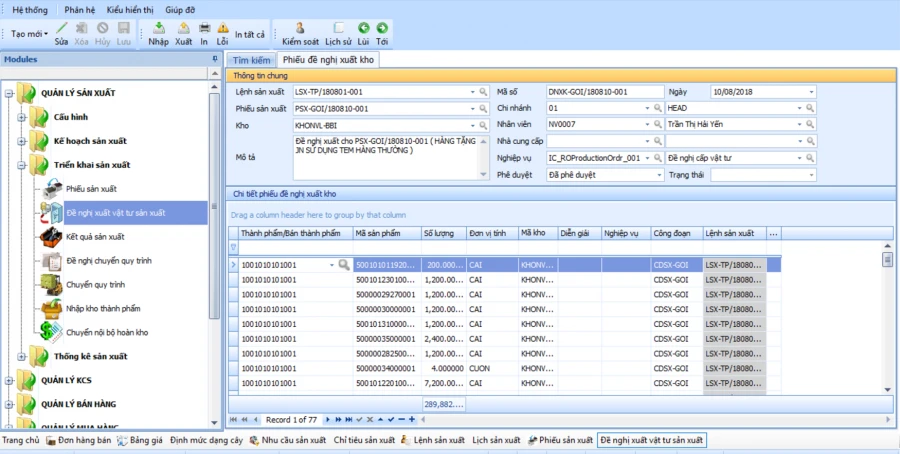

Proposed production materials

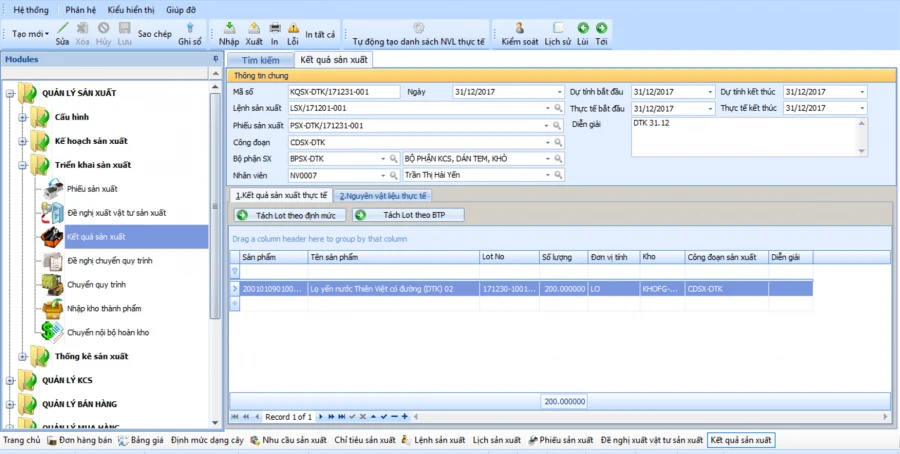

Production results

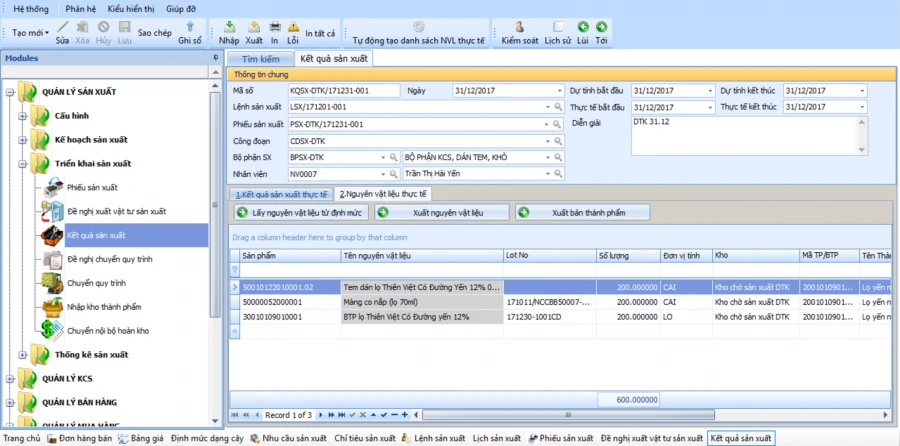

Record the actual materials of production results

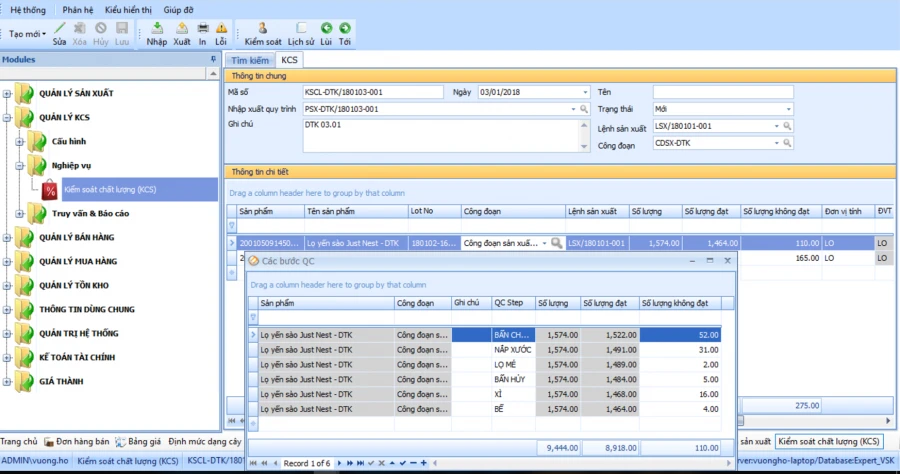

Record KCS

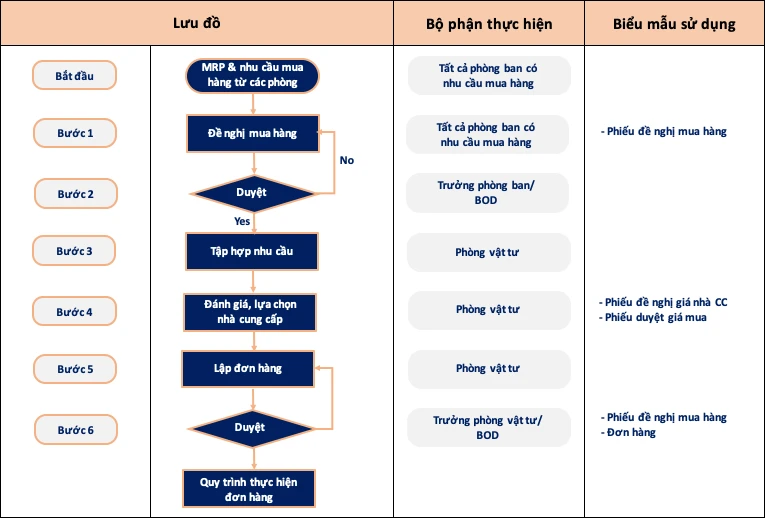

PURCHASING PROCESS

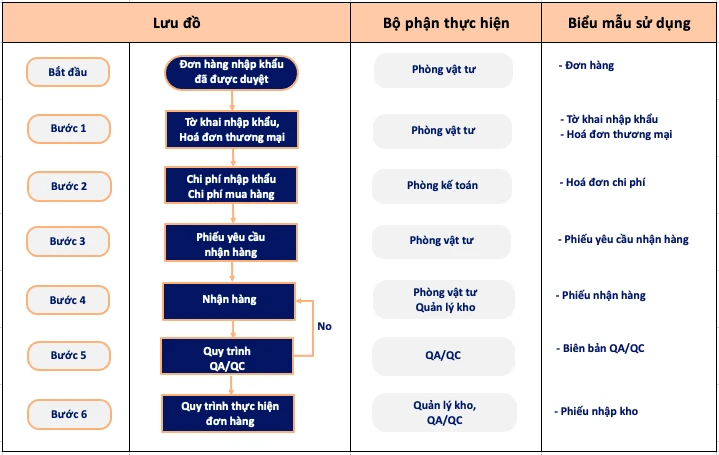

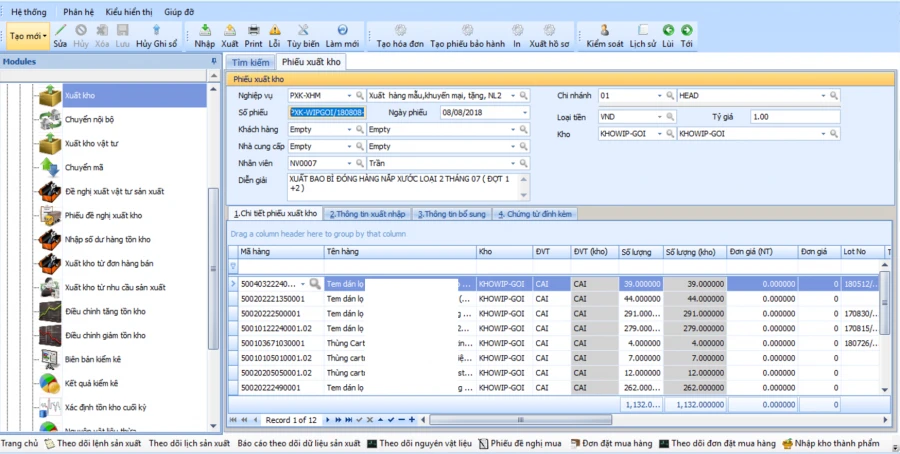

ORDER FULFILLMENT PROCESS

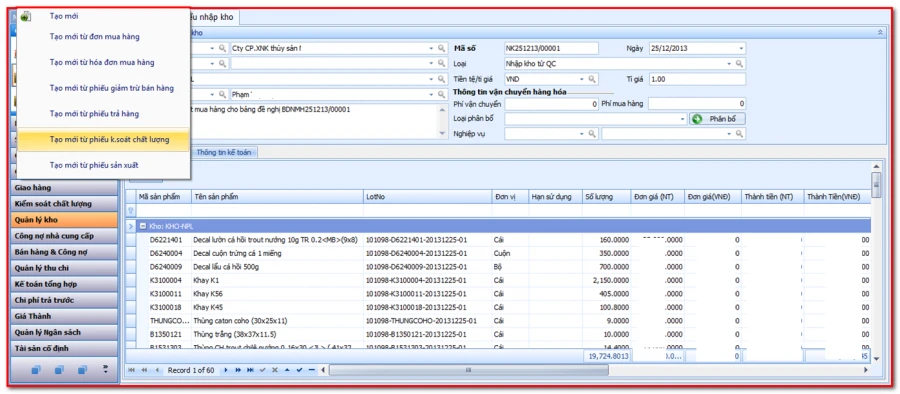

RECEIVING PROCESS

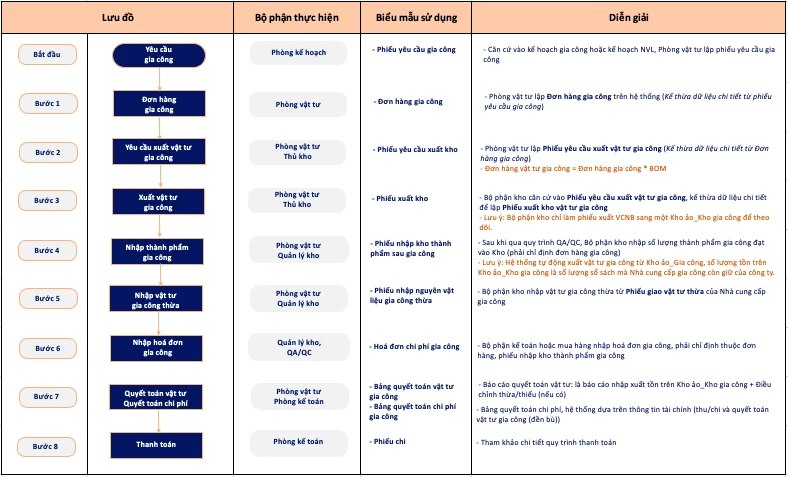

MACHINING PROCESS

Material Planning

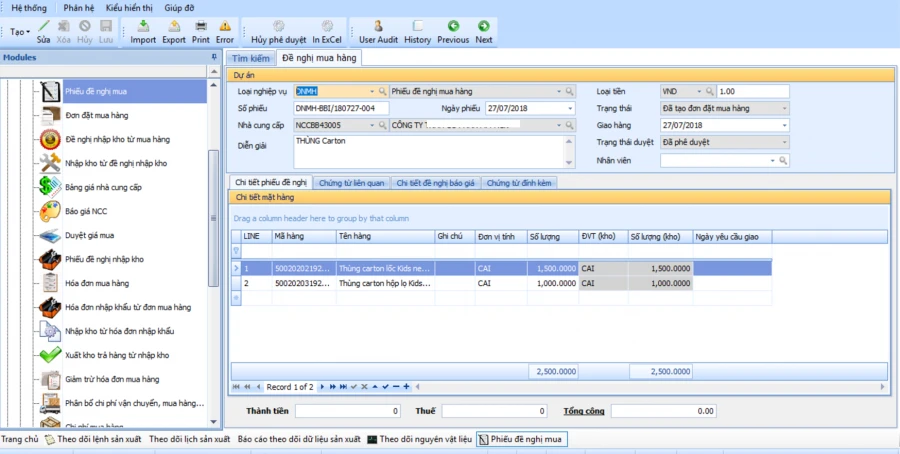

Purchase Request

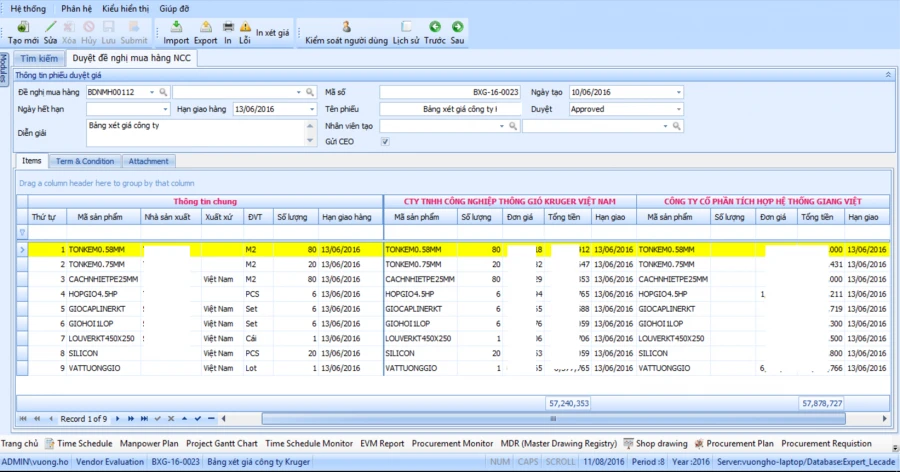

Supplier Evaluation

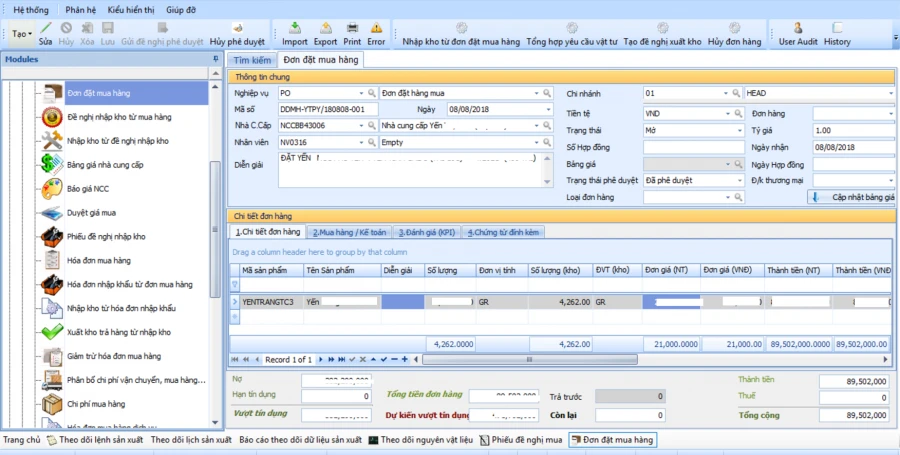

Purchase order

Purchase Status

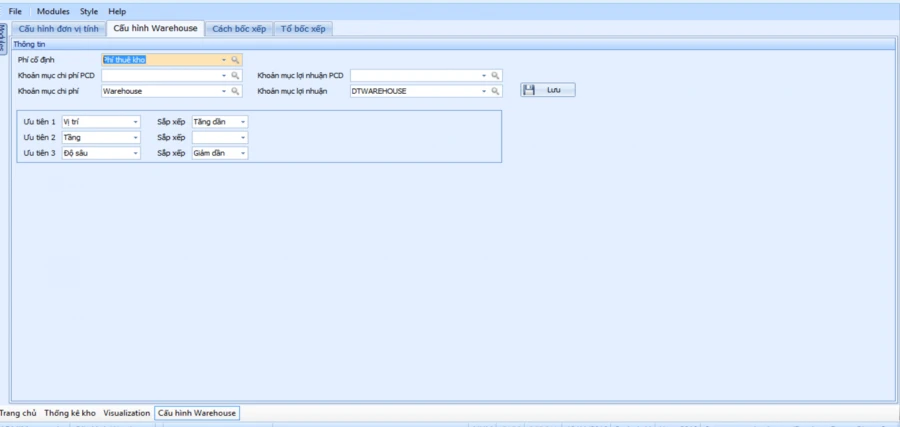

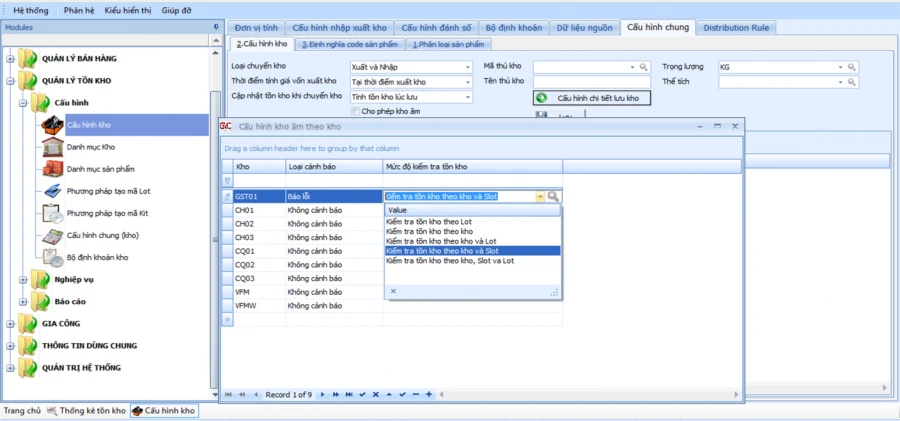

Allows automatic support for prioritizing the sorting of rows by:

Location

Floor

Depth

By sorting method: Ascending/Descending

Configure warehouse arrangement method

Import material warehouse

Export material warehouse

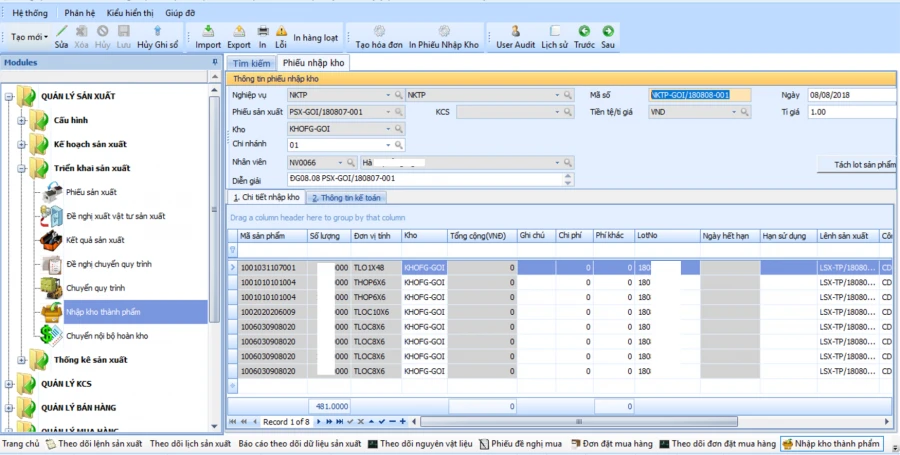

Stock Finish-Goods Receive

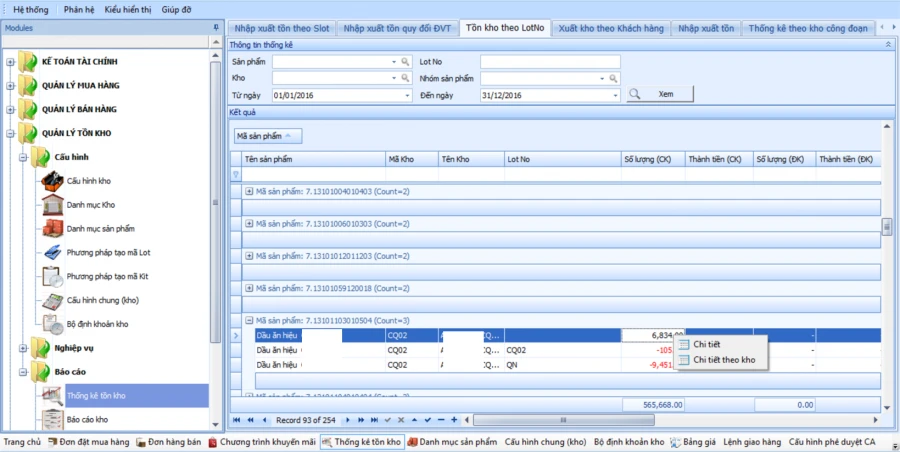

Batch inventory tracking

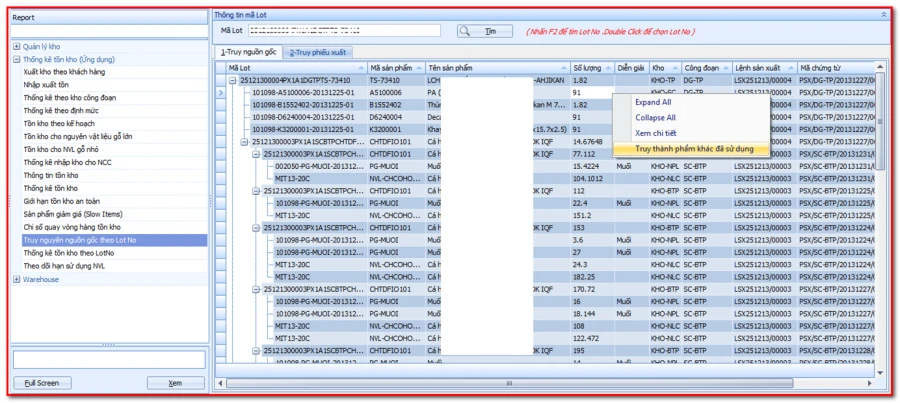

Traceability

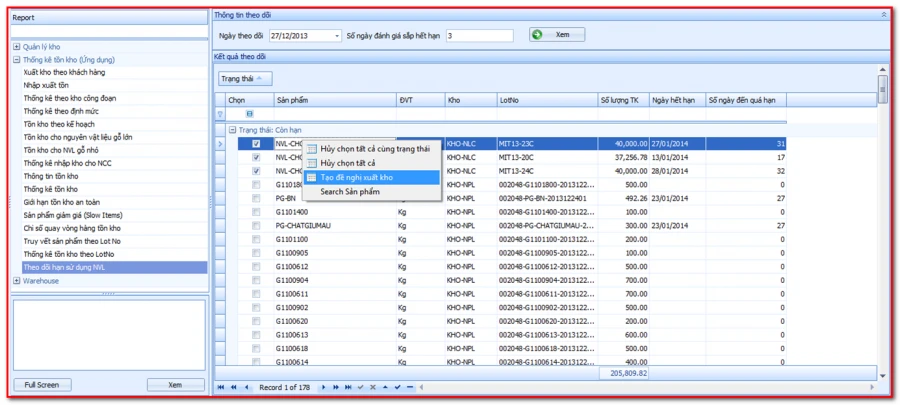

Tracking material expiry date

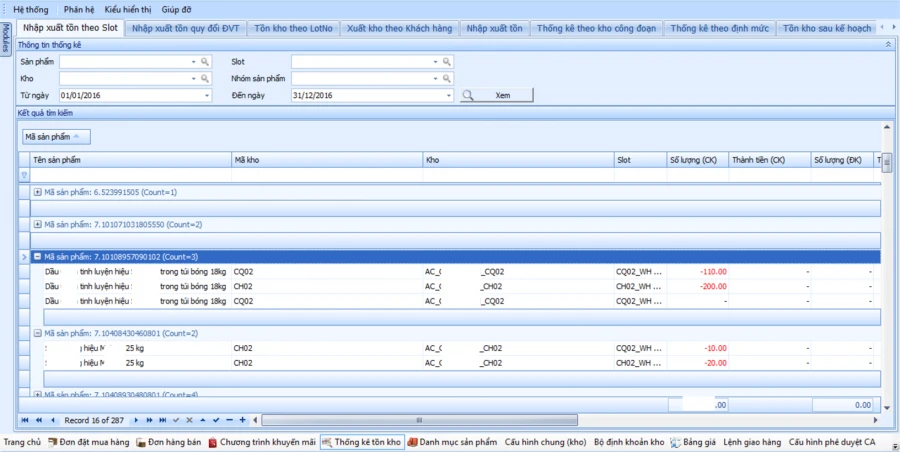

Inventory control by Warehouse, Area, Lot

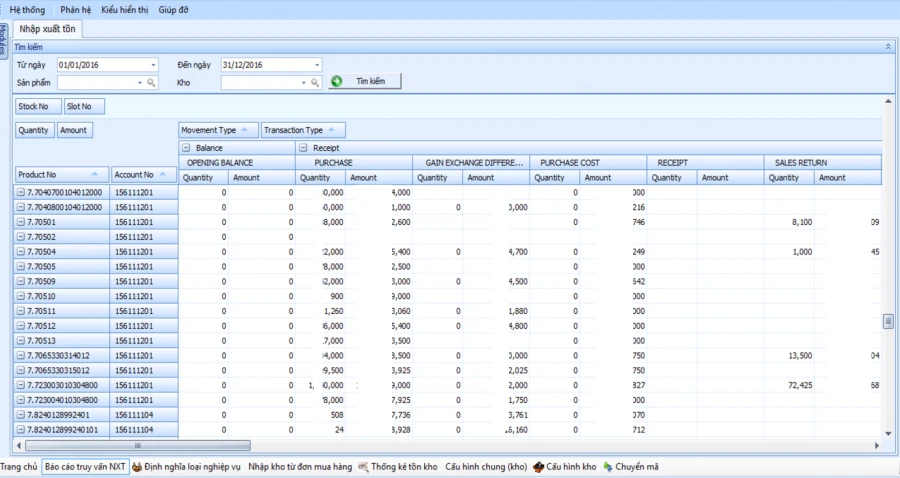

Track Import and Export Inventory by Movement Type

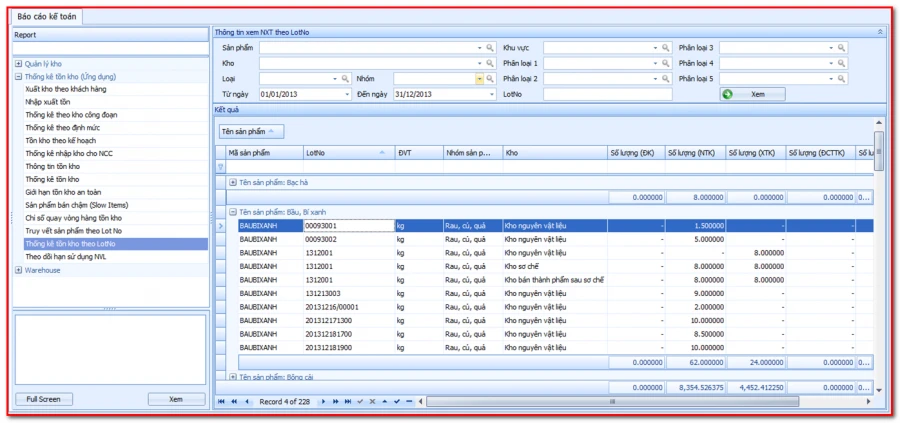

Track Import and Export Inventory by Lot

Track Import and Export Inventory by Warehouse Location

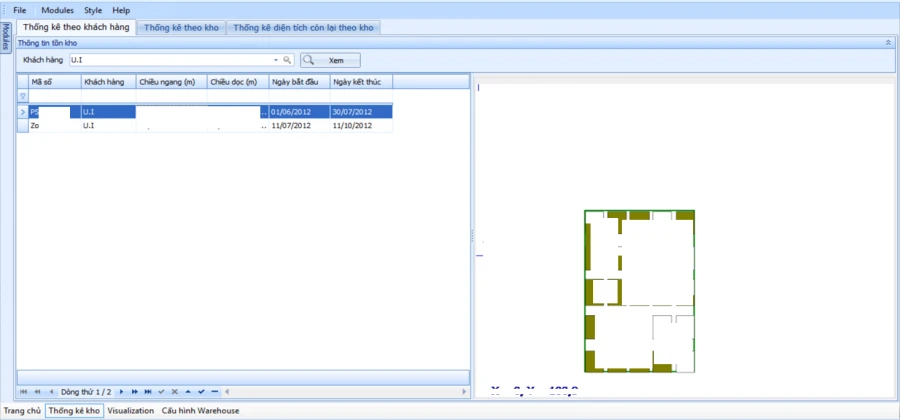

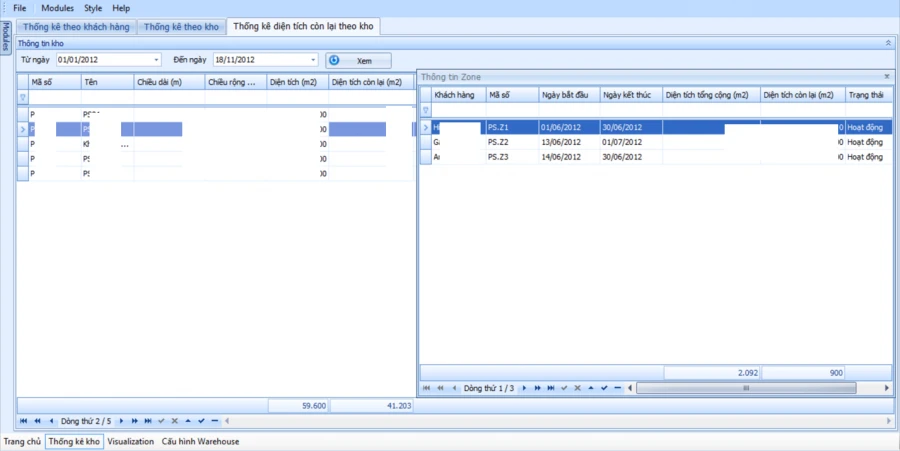

Track inventory by tenant

Track warehouse status

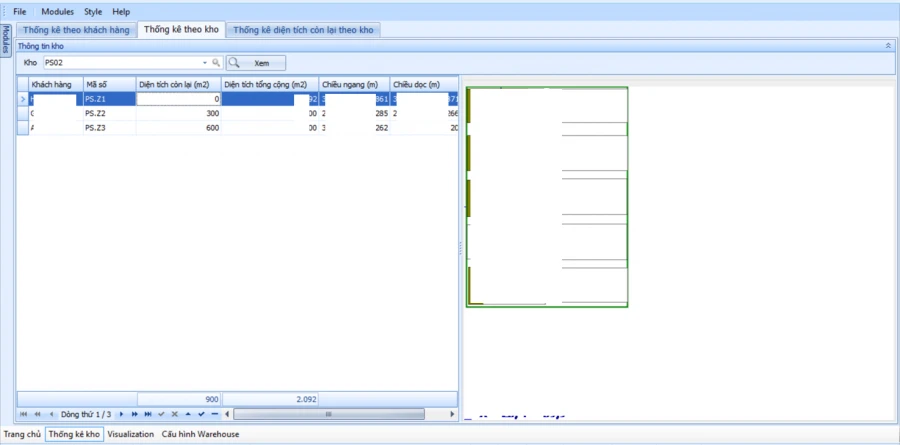

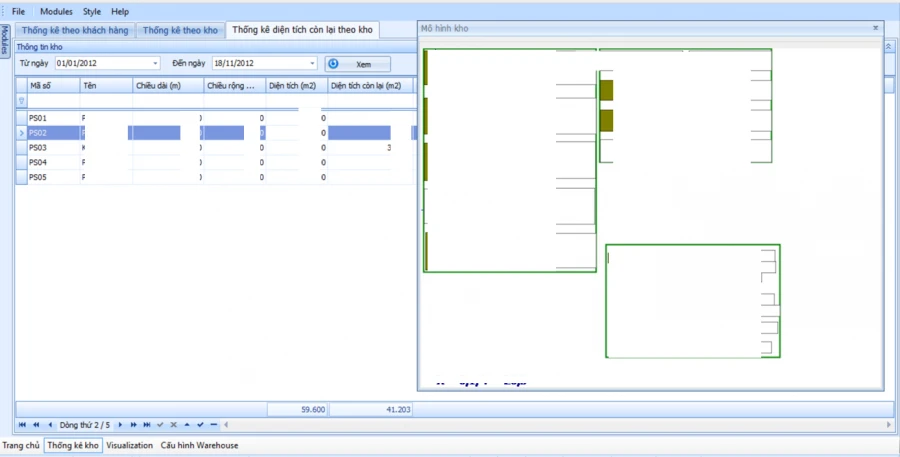

Track remaining space by warehouse

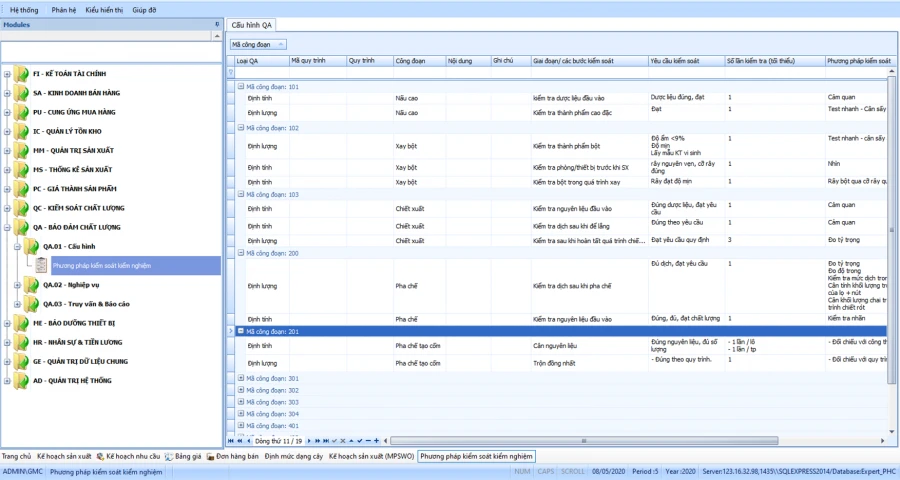

Quality management configuration

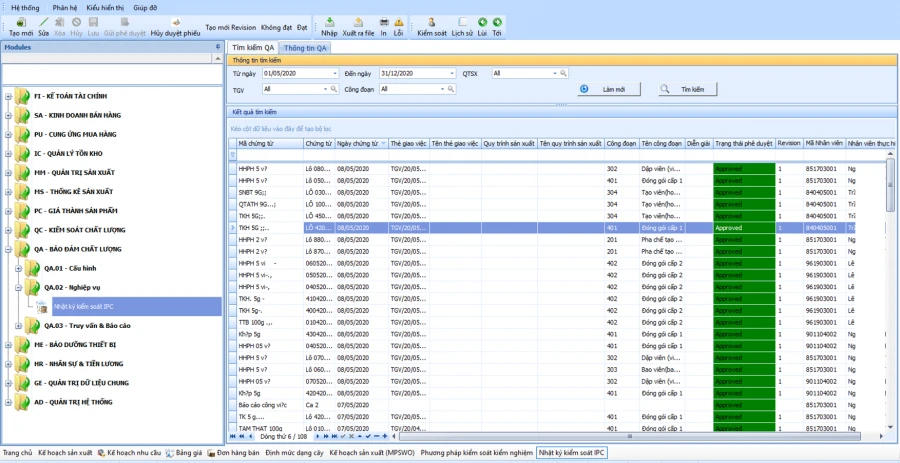

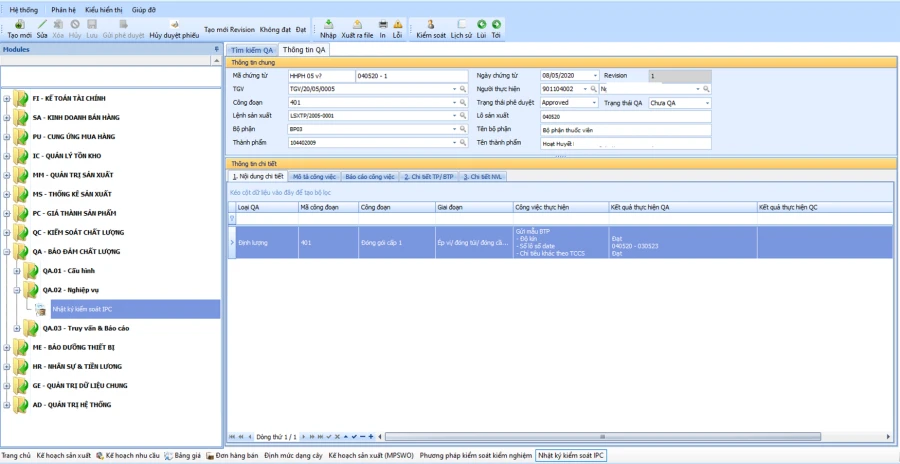

IPC Control Log

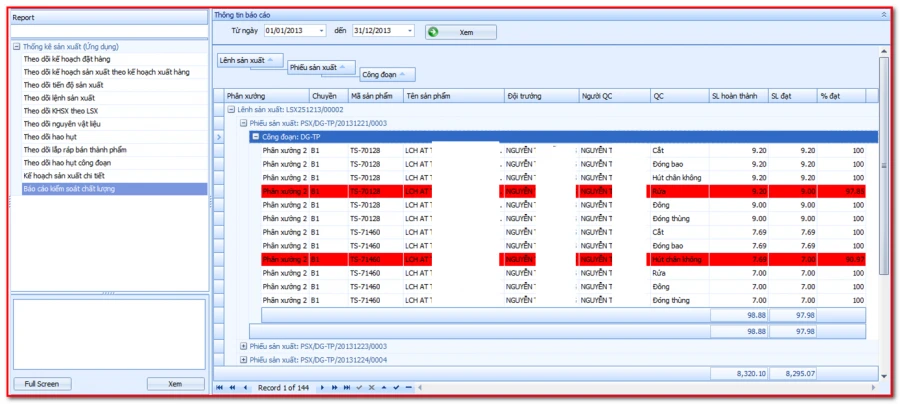

Quality control report

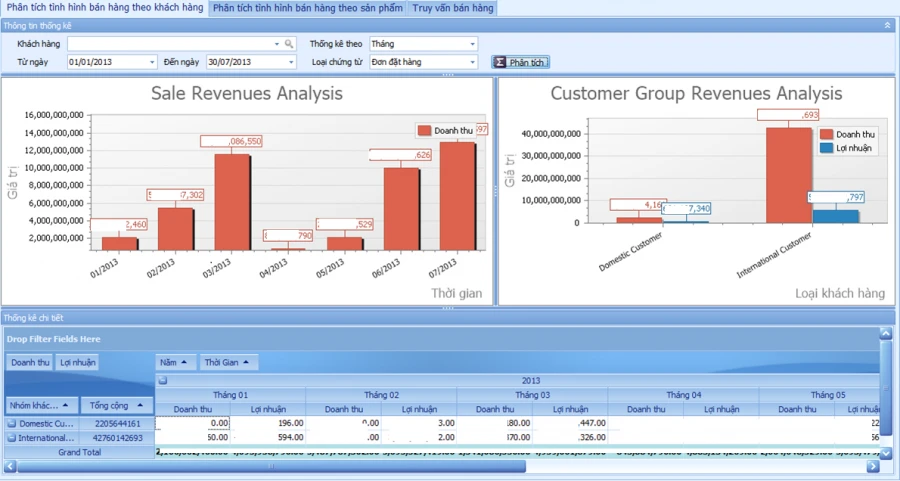

Sales Analysis

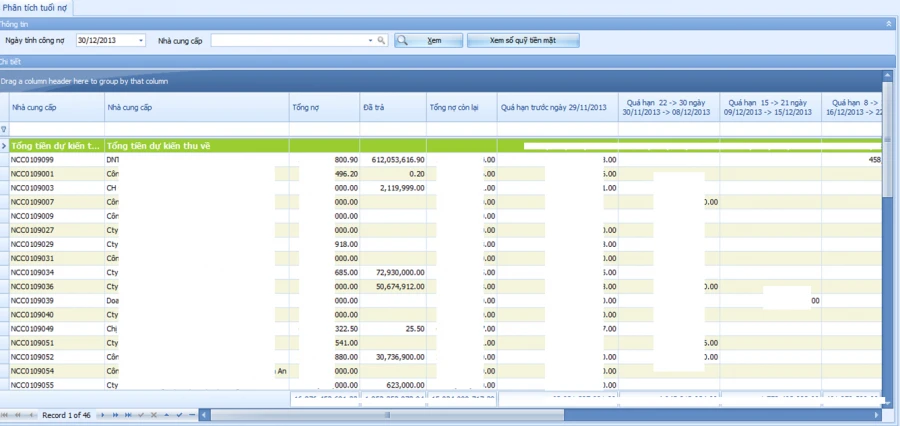

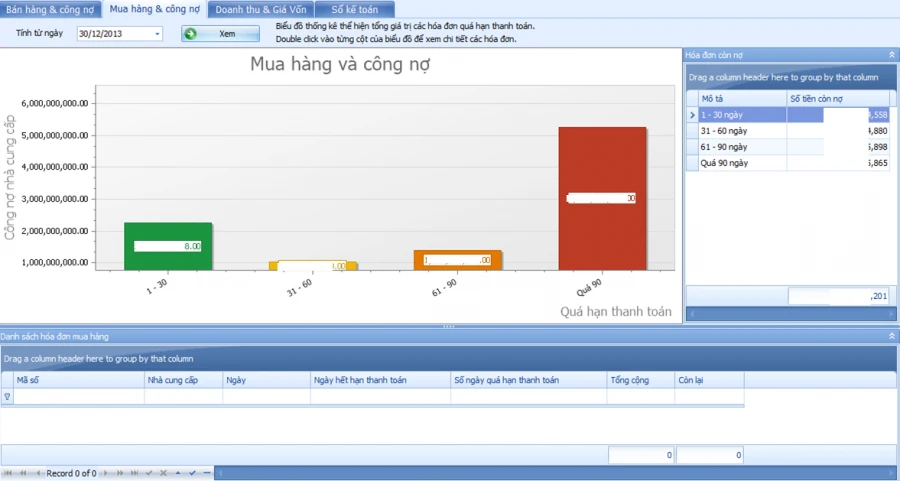

Purchases and accounts receivable/Payables

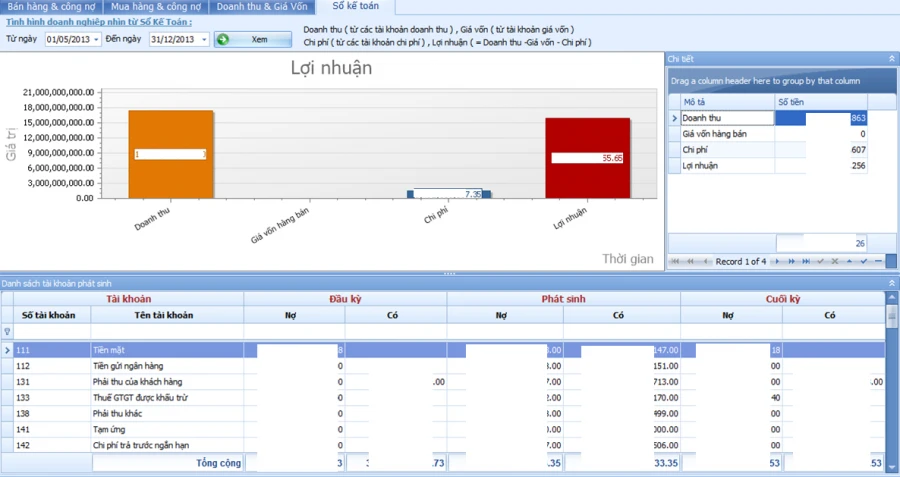

Business situation

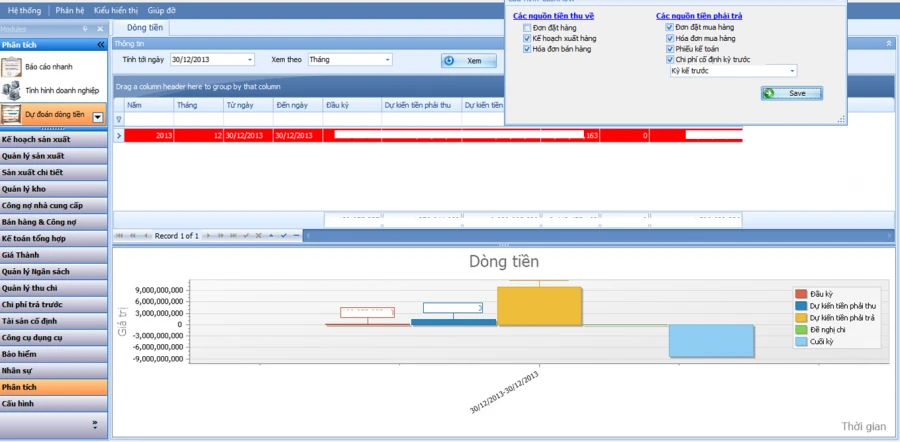

Cash flow forecasting

Monitor debt age